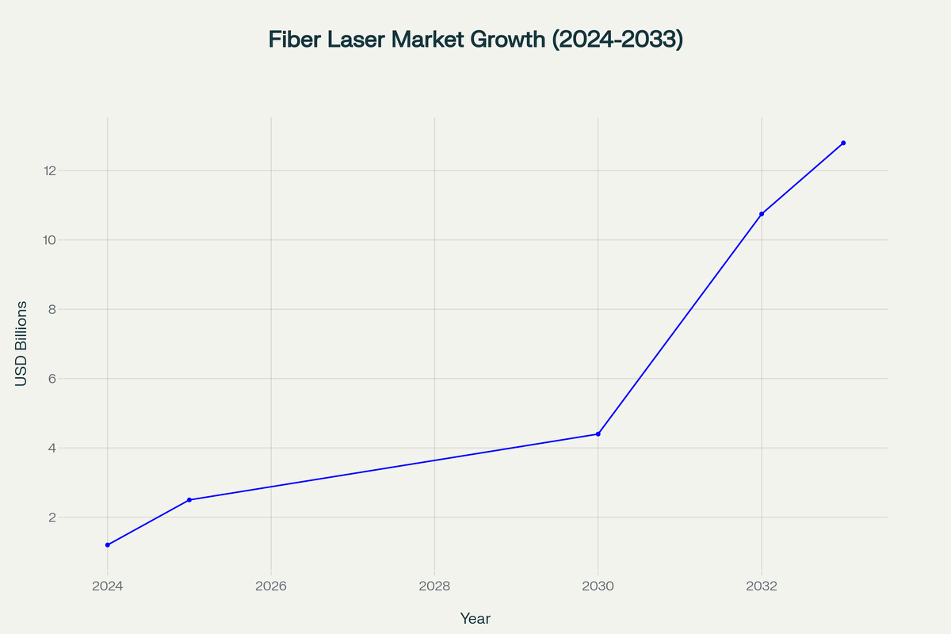

Selecting the optimal fiber-coupled laser source for your specific application requires careful consideration of multiple technical parameters, performance specifications, and industry requirements. With the global fiber-coupled laser market projected to reach $12.8 billion by 2033 at a CAGR of 10.8%, choosing the right laser source has never been more critical for maintaining competitive advantage in precision applications.

Global fiber-coupled laser market growth showing steady expansion from $1.2B in 2024 to $12.8B by 2033

Understanding Fiber-Coupled Laser Sources

Fiber-coupled laser sources represent sophisticated optical systems where laser output is precisely coupled into an optical fiber, enabling controlled light delivery with exceptional beam quality and stability. Unlike free-space lasers, fiber-coupled systems provide superior beam homogenization, circular intensity profiles, and enhanced system integration capabilities.

The fundamental advantage lies in their ability to deliver consistent, high-quality laser light through flexible fiber optic cables, making them ideal for applications requiring precise beam positioning, remote light delivery, and integration with complex optical systems.

Key Selection Criteria for Fiber-Coupled Laser Sources

Wavelength Selection: The Foundation of Performance

Wavelength choice fundamentally determines laser-material interaction efficiency and application suitability. The selection process requires understanding both material absorption characteristics and detector sensitivity requirements.

For research and microscopy applications, specific wavelengths offer distinct advantages:

- 405-488nm: Ideal for fluorescence microscopy and confocal imaging

- 638-660nm: Optimal for red fluorescent protein imaging

- 785nm: Balanced performance for Raman spectroscopy with reduced fluorescence interference

- 920-980nm: Essential for two-photon microscopy and deep tissue imaging

SUNLONGE’s SCL3000 series provides customizable wavelength options from 405nm to 980nm, offering unprecedented flexibility compared to standard fixed-wavelength systems that typically limit users to predetermined options.

Output Power Requirements: Balancing Performance and Safety

Laser output power directly impacts processing speed, signal quality, and application effectiveness. Power requirements vary significantly across applications:

- Low power (1-10mW): Suitable for spectroscopy and sensitive biological imaging

- Medium power (20-50mW): Optimal for confocal microscopy and material characterization

- High power (100mW+): Required for material processing and industrial applications

The SUNLONGE SCL3000 delivers 20-30mW per wavelength channel, providing sufficient power for demanding microscopy applications while maintaining safe operation parameters for biological samples.

Fiber Type Selection: Single Mode vs. Multimode vs. Polarization-Maintaining

Fiber type selection significantly impacts beam quality, polarization control, and system performance:

Single Mode Fiber (SMF):

- Core diameter: 8-10μm

- Superior beam quality (M² < 1.2)

- Minimal modal dispersion

- Ideal for precision applications requiring diffraction-limited performance[14]

Multimode Fiber (MMF):

- Core diameter: 50-100μm

- Higher power handling capability

- Reduced coupling efficiency requirements

- Suitable for power delivery and illumination applications[14]

Polarization-Maintaining (PM) Fiber:

- Maintains linear polarization state

- Essential for interferometry and polarization-sensitive measurements

- Extinction ratio >20dB at design wavelength

SUNLONGE’s SCL3000 utilizes single-mode polarization-maintaining fiber coupling, ensuring both superior beam quality and polarization stability for advanced research applications.

Beam Quality and Stability: Critical Performance Parameters

Beam quality, measured by the M² factor, quantifies how closely a real laser beam approaches ideal Gaussian beam performance. Lower M² values indicate superior focusing capability and beam propagation characteristics:

- M² = 1.0: Perfect Gaussian beam (theoretical ideal)

- M² < 1.5: Excellent beam quality for precision applications

- M² > 2.0: Acceptable for general illumination but limited focusing capability

Power stability is equally critical, with typical requirements including:

- Power fluctuation <0.15% RMS for precision measurements

- Long-term drift <1% over operational temperature range

- Fast settling time after power adjustments

Modulation Capabilities: Enabling Advanced Applications

Modulation frequency determines system responsiveness for time-resolved measurements and dynamic applications:

- DC to 1kHz: Suitable for steady-state measurements

- 1kHz to 100kHz: Required for fluorescence lifetime imaging and fast switching

- >100kHz: Essential for high-speed imaging and communication applications

Industry-Specific Application Requirements

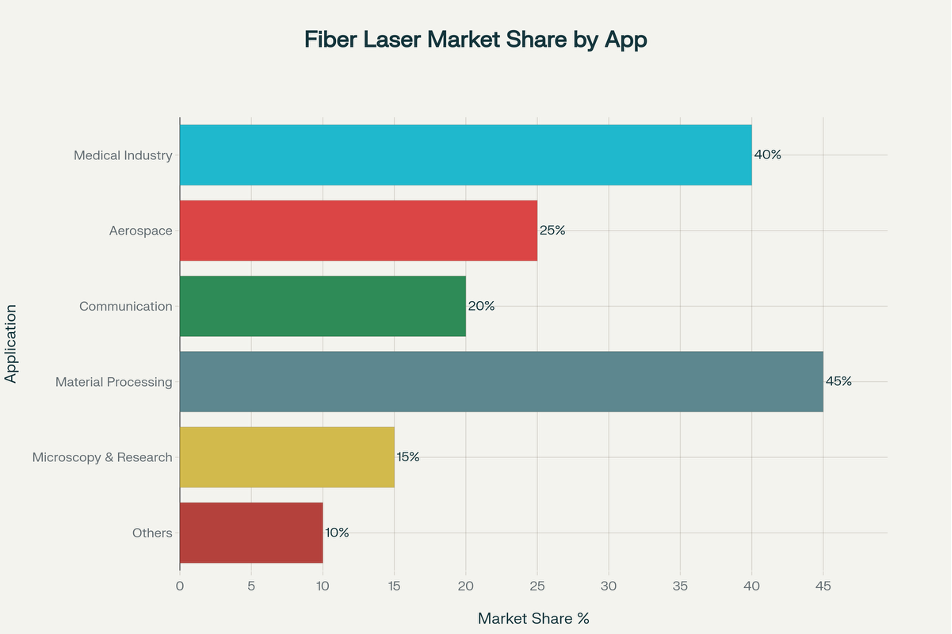

Market share distribution across key application sectors for fiber-coupled laser sources

Research and Microscopy Applications

Confocal and Super-Resolution Microscopy requires exceptional beam quality and wavelength precision. Key specifications include:

- Beam quality M² < 1.2 for optimal focusing

- Wavelength stability ±0.1nm over operational range

- Low noise operation for sensitive detection

Two-Photon Microscopy demands specific wavelength and power characteristics:

- Wavelengths: 780nm, 920nm, or 1050nm for optimal protein excitation

- High peak power with low average power to minimize photodamage

- Femtosecond pulse capability for efficient multiphoton absorption

Industrial Inspection and Quality Control

Material characterization and defect detection applications require:

- Wavelength selection based on material absorption properties

- High power stability for consistent measurement results

- Robust construction for industrial environments

Semiconductor inspection benefits from shorter wavelengths (405-488nm) for enhanced resolution and contrast, while metal analysistypically employs near-infrared wavelengths (785-980nm) for deeper penetration.

Photonics and Telecommunications

Fiber optic testing and characterization requires:

- Precise wavelength control for spectral analysis

- Low noise operation for sensitive measurements

- Compatibility with standard fiber optic components

SUNLONGE’s Competitive Advantages in Fiber-Coupled Laser Sources

Superior Technical Specifications

SUNLONGE’s SCL3000 series offers several key advantages over conventional fiber-coupled laser sources:

| Parameter | Standard Lasers | SUNLONGE SCL3000 | Competitive Advantage |

| Wavelength Range | Limited options | 405-980nm customizable | Wide customization flexibility |

| Output Power | 10-100mW | 20-30mW per channel | Optimized power delivery |

| Fiber Type | Single mode only | Single mode PM | Enhanced polarization control |

| Beam Quality (M²) | 1.2-1.8 | <1.2 | Superior beam quality |

| Stability | Standard | High stability | Enhanced measurement reliability |

| Modulation Frequency | Up to 50kHz | Up to 100kHz | Higher frequency response |

Advanced Integration and Ease of Use

Highly integrated design eliminates external control boxes and complex setup procedures. The SCL3000 integrates control electronics, temperature management, and laser driver circuits in a compact 186×160×63mm package.

Remote control capability enables automated operation with 10-100% power adjustment through manual knobs or external control signals, essential for system integration and automated testing protocols.

Cost-Effective Custom Solutions

Unlike competitors offering only standard wavelengths, SUNLONGE provides custom wavelength development to meet specific application requirements. This capability is particularly valuable for specialized research applications requiring non-standard excitation wavelengths.

Market Growth and Future Trends

The fiber-coupled laser source market demonstrates robust growth across multiple sectors. Material processing applications dominate with 45% market share, followed by medical applications at 40%. This growth reflects increasing adoption of precision laser technologies in advanced manufacturing and biomedical research.

Key market drivers include:

- Expanding automation in manufacturing processes

- Growing demand for precision medical procedures

- Increasing adoption in scientific research and development

- Rising requirements for non-invasive testing methods

Selection Framework: Step-by-Step Decision Process

Step 1: Define Application Requirements

- Identify target materials and interaction mechanisms

- Determine required spatial resolution and working distance

- Establish power and energy requirements

- Define environmental and safety constraints

Step 2: Wavelength Optimization

- Analyze material absorption spectra

- Consider detector sensitivity characteristics

- Evaluate fluorescence and background interference

- Select optimal wavelength for application efficiency

Step 3: Power and Beam Quality Specification

- Calculate minimum power requirements for signal-to-noise ratio

- Determine beam quality needs based on focusing requirements

- Consider safety classifications and user protection

Step 4: System Integration Considerations

- Evaluate fiber coupling requirements and connector types

- Assess modulation and control interface needs

- Consider environmental stability and mounting requirements

- Plan for maintenance and service accessibility

Step 5: Performance Validation

- Verify specifications meet application requirements

- Conduct pilot testing with representative samples

- Evaluate long-term stability and reliability

- Assess total cost of ownership including maintenance

Frequently Asked Questions (Q&A)

Q: What is the difference between single-mode and multimode fiber-coupled lasers?

A: Single-mode fibers have smaller core diameters (8-10μm) and provide superior beam quality with M² values approaching 1.0, making them ideal for precision applications requiring tight focusing. Multimode fibers feature larger cores (50-100μm) and can handle higher powers but sacrifice beam quality. SUNLONGE’s SCL3000 uses single-mode polarization-maintaining fiber for optimal performance in research applications.

Q: How important is polarization-maintaining (PM) fiber for my application?

A: PM fiber is critical for applications requiring polarization control, such as interferometry, polarization-sensitive spectroscopy, and certain microscopy techniques. PM fiber maintains linear polarization state with extinction ratios >20dB, preventing polarization fluctuations that can affect measurement accuracy. Standard single-mode fiber cannot preserve polarization state over long distances.

Q: What wavelength should I choose for Raman spectroscopy applications?

A: 785nm is the most commonly used wavelength for Raman spectroscopy as it provides optimal balance between Raman scattering efficiency and fluorescence suppression. However, wavelength selection depends on sample properties: 532nm offers higher Raman intensity but may cause fluorescence, while 1064nm minimizes fluorescence but reduces signal strength. SUNLONGE offers customizable wavelengths to optimize performance for specific sample types.

Q: How do I determine the required output power for my application?

A: Power requirements depend on several factors: sample properties, detection sensitivity, measurement speed, and safety considerations. For fluorescence microscopy, 1-10mW is typically sufficient. Raman spectroscopy may require 10-50mW depending on sample concentration and acquisition time. Material processing applications need 100mW or higher. The SUNLONGE SCL3000’s 20-30mW output is optimized for most research applications.

Q: What beam quality (M²) should I expect from fiber-coupled laser sources?

A: High-quality fiber-coupled lasers should achieve M² values below 1.5 for precision applications. SUNLONGE’s SCL3000 achieves M² <1.2, approaching diffraction-limited performance. This superior beam quality enables tighter focusing, better spatial resolution, and more efficient coupling into optical systems compared to sources with higher M² values.

Q: Can fiber-coupled lasers be modulated for time-resolved measurements?

A: Yes, modern fiber-coupled lasers offer various modulation capabilities. The SUNLONGE SCL3000 supports modulation frequencies up to 100kHz, enabling applications such as fluorescence lifetime imaging, fast switching between measurement conditions, and synchronization with detection systems. Modulation capability is essential for advanced research techniques requiring temporal control.

Q: What are the advantages of integrated laser systems versus modular approaches?

A: Integrated systems like SUNLONGE’s SCL3000 combine laser, driver, temperature control, and safety systems in a single compact unit. This approach offers several advantages: reduced complexity, improved reliability, easier installation, and lower total cost. Modular systems provide more flexibility but require expertise in system integration and may introduce additional noise sources.

Q: How do environmental factors affect fiber-coupled laser performance?

A: Temperature fluctuations can cause wavelength drift and power variations. Quality laser systems include active temperature stabilization to maintain specifications across operating ranges. Mechanical vibrations can affect fiber coupling efficiency and beam stability. The SCL3000’s integrated thermal management ensures consistent performance in laboratory environments.

Conclusion

Selecting the optimal fiber-coupled laser source requires systematic evaluation of wavelength requirements, power specifications, fiber type, beam quality, and application-specific needs. SUNLONGE’s SCL3000 series addresses these requirements with customizable wavelengths, superior beam quality (M² <1.2), polarization-maintaining fiber coupling, and integrated design.

The global fiber-coupled laser market’s projected growth to $12.8 billion by 2033 reflects increasing demand for precision laser solutions across research, medical, and industrial applications. Organizations investing in high-quality fiber-coupled laser sources position themselves for success in increasingly competitive markets requiring exceptional precision and reliability.

By following the systematic selection framework outlined in this guide and considering SUNLONGE’s competitive advantages, users can confidently choose fiber-coupled laser sources that meet current needs while providing headroom for future application expansion.

CN

CN