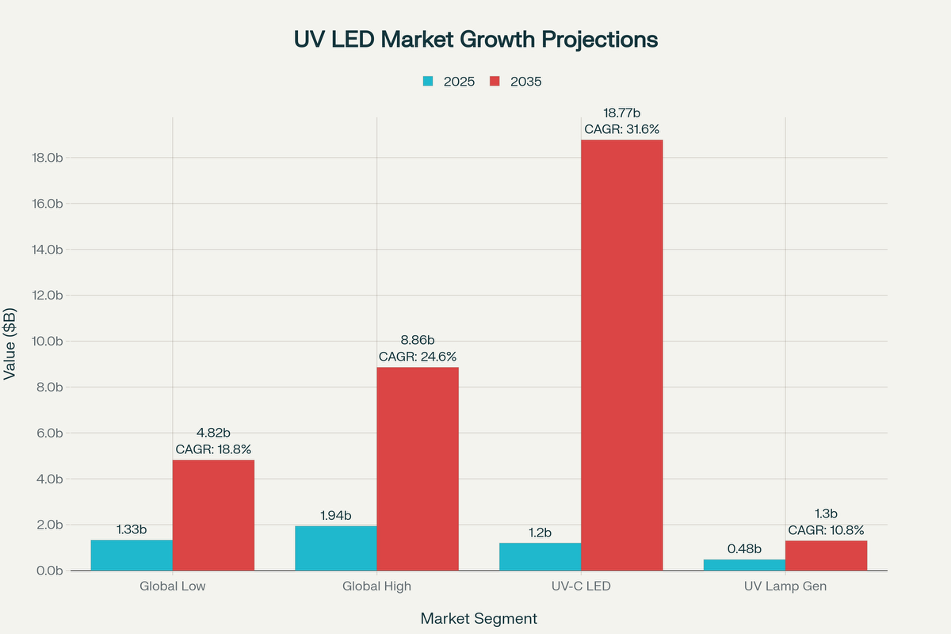

The ultraviolet LED lamp industry is experiencing unprecedented growth, with the global market projected to reach $8.86 billion by 2035at a remarkable 24.6% CAGR. This explosive expansion is driven by revolutionary advances in LED technology that are rapidly replacing traditional mercury-based systems across industries. At the forefront of this transformation stands Sunlonge International, a Hong Kong-based pioneer with over 25 years of UV lamp expertise, delivering cutting-edge UV LED lamp solutions that outperform conventional alternatives in virtually every metric.

UV LED Market Growth Projections (2025-2035) showing the exponential growth expected across different market segments

Understanding UV LED Lamp Technology

UV LED lamps represent a paradigm shift in ultraviolet lighting technology. Unlike traditional mercury vapor lamps that generate UV light through gas discharge, UV LEDs use semiconductor diodes made from aluminum gallium nitride or gallium nitride to emit precise wavelengths of ultraviolet radiation. This fundamental difference creates numerous advantages that make UV LED technology the superior choice for modern industrial applications.

The technology operates by passing an electric current through semiconductor materials, which directly converts electrical energy into UV photons without requiring gas ionization or thermal processes. This direct conversion mechanism enables instant startup, eliminates mercury contamination, and provides unprecedented control over wavelength output and intensity.

Market Dynamics Driving UV LED Adoption

The UV LED market is experiencing explosive growth across multiple sectors. The UV-C LED segment alone is projected to grow from $1.2 billion in 2025 to $18.77 billion by 2035, representing a staggering 31.6% CAGR. This growth is primarily driven by:

Industrial Curing Applications: The shift from mercury lamps to UV LEDs in industrial curing processes is accelerating, with UV LEDs offering 30-70% energy savings and eliminating warm-up times. Industries including automotive, electronics, and printing are rapidly adopting UV LED curing systems for adhesives, coatings, and inks.

Non-Destructive Testing (NDT): The NDT sector is increasingly adopting UV LED lamps for fluorescent penetrant inspection and magnetic particle testing. UV LED systems provide superior defect detection accuracy with up to 99% improved precision compared to traditional methods.

Disinfection and Sterilization: Post-pandemic demand for chemical-free disinfection has driven massive adoption of UV-C LEDs in healthcare, water treatment, and air purification systems.

Sunlonge’s Competitive Advantages in UV LED Technology

Advanced NICHIA LED Integration

Sunlonge’s UV LED lamps utilize premium NICHIA 5W 365nm LED technology, representing the pinnacle of UV LED engineering. The SL6300 series delivers exceptional performance with UV intensity ranging from 4,000 to 35,000 μW/cm² at 15 inches, far exceeding industry standards. This precision wavelength control ensures optimal fluorescence activation for NDT applications while maintaining >85% intensity stability throughout the LED’s 30,000-hour lifespan.

Industry-Leading Certifications

Sunlonge’s commitment to quality is demonstrated through comprehensive industry certifications. Their UV LED lamps meet stringent ASTM E1417, E1444, E709, E2297, and E3022 standards for fluorescent penetrant and magnetic particle inspection. The aerospace-grade SL6300-AR model specifically meets Rolls-Royce RRES 90061 requirements, positioning Sunlonge as a trusted supplier for the most demanding applications.

Innovative Design Features

Adjustable Beam Technology: Sunlonge’s patented adjustable beam system allows users to modify the illuminated area from 30mm to 100mm diameter by adjusting the lens focus. This versatility enables precise inspection of various component sizes without requiring multiple lamp models.

Dual Power Capability: The SL8104 series features both AC and rechargeable battery operation, providing unparalleled flexibility for laboratory and field applications. The high-capacity 2200mAh lithium battery delivers 2.5 hours of continuous operation.[9]

Ergonomic Design: Weighing only 160 grams, Sunlonge’s UV LED flashlights reduce operator fatigue during extended inspection periods while maintaining professional durability through robust aluminum alloy construction.

UV LED vs. Mercury Lamp Performance Analysis

The technical superiority of UV LED technology over traditional mercury lamps is evident across multiple performance metrics:

Energy Efficiency Revolution

UV LED lamps consume 60-70% less energy than equivalent mercury vapor systems. This dramatic efficiency improvement translates to significant operational cost savings, particularly in high-usage industrial environments. Traditional mercury lamps operate at approximately 30% wall-plug efficiency, meaning a 10W mercury lamp delivers only 1-3W of useful UV output. In contrast, UV LEDs achieve direct energy conversion with minimal heat generation, maximizing useful UV output per watt consumed.

Lifespan and Reliability

UV LED lifespan exceeds 25,000-30,000 hours compared to mercury lamps’ typical 1,000-8,000 hours. This 3-10x lifespan advantage dramatically reduces maintenance costs and equipment downtime. Sunlonge’s UV LED lamps maintain >90% of initial intensitythroughout their operational life, ensuring consistent performance without the gradual degradation common in mercury systems.

Operational Advantages

Instant Startup: UV LEDs activate immediately upon power application, eliminating the 30 seconds to 2 minutes warm-up timerequired by mercury lamps. This instant-on capability enables more efficient workflows and reduces energy waste during standby periods.

Temperature Control: UV LEDs generate minimal heat compared to mercury lamps, preventing thermal damage to heat-sensitive materials. This low-temperature operation expands application possibilities and improves workplace safety.

Environmental Safety: UV LEDs contain no mercury or hazardous materials and produce no ozone, creating safer working environments while eliminating complex disposal requirements.

Industrial Applications and Use Cases

Non-Destructive Testing Excellence

UV LED lamps have revolutionized NDT applications through superior fluorescence detection capabilities. The precise 365nm wavelength output optimally activates fluorescent penetrants and magnetic particles, revealing surface cracks and defects with unprecedented clarity. Industries including aerospace, automotive, and oil & gas rely on UV LED systems for:

- Aircraft component inspection for fatigue crack detection

- Pipeline integrity assessment using magnetic particle testing

- Pressure vessel examination in power generation facilities

- Automotive engine block quality control processes

Leak Detection Systems

UV LED technology has transformed automotive leak detection, achieving 99% accuracy in identifying system leaks. The fluorescent dye method using UV LED illumination enables rapid identification of leaks in:

- Air conditioning systems with refrigerant leak detection

- Engine oil circulation pathways

- Coolant system integrity verification

- Transmission fluid leak identification

Industrial Curing Applications

The industrial curing market is rapidly adopting UV LED systems for their instant curing capabilities and energy efficiency. Key applications include:

- Adhesive bonding in electronics assembly

- Coating applications for automotive parts

- Ink curing in commercial printing

- Composite material processing in aerospace

Technical Specifications and Performance Data

Sunlonge SL6300 Series Performance Matrix

| Specification | SL6300-Standard | SL6300-Aerospace |

| UV Intensity | 35,000 μW/cm² @ 15″ | 3,500 μW/cm² @ 15″ |

| Wavelength | 365-370nm | 365-370nm |

| LED Life | 30,000 hours | 30,000 hours |

| Battery Life | 2.5 hours continuous | 2.5 hours continuous |

| Beam Diameter | 30-100mm adjustable | 50-100mm adjustable |

| Weight | 160g | 160g |

| Certifications | ASTM compliant | RRES 90061 certified |

Energy Consumption Comparison

UV LED Systems:

- Power consumption: 5-15 watts

- UV output efficiency: >40%

- Heat generation: Minimal

- Operational cost: $0.02-0.05/hour

Mercury Lamp Systems:

- Power consumption: 50-400 watts

- UV output efficiency: 10-30%

- Heat generation: Significant cooling required

- Operational cost: $0.15-0.50/hour

Quality Assurance and Manufacturing Excellence

Sunlonge’s manufacturing philosophy centers on precision engineering and quality control. Established in 1999 with headquarters in Hong Kong and manufacturing facilities in mainland China, the company maintains comprehensive R&D capabilities that enable continuous innovation in UV LED technology.

Quality Control Processes

- 100% LED testing before assembly

- Calibrated intensity measurements for each unit

- Accelerated aging tests to verify lifespan claims

- Environmental stress testing for durability validation

- Wavelength accuracy verification to ±1nm tolerance

Manufacturing Standards

Sunlonge’s facilities operate under ISO quality management systems and maintain clean room environments for LED assembly. This controlled manufacturing approach ensures consistent product quality and reliability across all product lines.

Future Technology Trends and Innovations

Deep UV LED Development

The industry is advancing toward deeper UV wavelengths (200-280nm) for enhanced disinfection applications. Sunlonge is actively developing UV-C LED products to address growing demand in water treatment and air purification markets.

Smart Integration Capabilities

Next-generation UV LED systems will incorporate IoT connectivity and smart monitoring features, enabling remote diagnostics, usage tracking, and predictive maintenance capabilities. This evolution will further enhance the value proposition of UV LED technology over traditional alternatives.

Efficiency Improvements

Ongoing research in AlGaN semiconductor technology promises continued improvements in UV LED efficiency, with projections indicating 12% annual increases in UV output power. These advances will further strengthen the cost-effectiveness argument for UV LED adoption.

Economic Analysis and Return on Investment

Total Cost of Ownership Comparison

5-Year Operating Cost Analysis (Per Unit):

UV LED System (Sunlonge SL6300):

- Initial cost: $800-1,200

- Energy costs: $150

- Maintenance/replacement: $50

- Total 5-year cost: $1,000-1,400

Mercury Lamp System (Equivalent):

- Initial cost: $400-600

- Energy costs: $750

- Lamp replacements: $400

- Maintenance labor: $300

- Total 5-year cost: $1,850-2,050

Productivity Benefits

Beyond direct cost savings, UV LED systems provide significant productivity advantages:

- Zero warm-up time increases equipment utilization by 15-20%

- Reduced maintenance minimizes production interruptions

- Consistent performance improves inspection reliability and reduces rework

- Portable operation enables field inspections without power infrastructure

Environmental Impact and Sustainability

UV LED technology aligns with global sustainability initiatives through multiple environmental benefits:

Mercury Elimination

Traditional UV lamps contain 5-10mg of mercury per unit, creating disposal challenges and environmental hazards. UV LEDs contain no hazardous materials, simplifying end-of-life handling and reducing environmental impact.

Energy Conservation

The 60-70% energy reduction achieved by UV LED systems significantly reduces carbon footprint. For large industrial operations, this efficiency improvement can eliminate thousands of tons of CO2 emissions annually.

Waste Reduction

The 25,000+ hour lifespan of UV LEDs dramatically reduces replacement frequency, minimizing packaging waste and transportation impacts associated with frequent lamp changes.

Frequently Asked Questions

Q: How do UV LED lamps compare to mercury lamps in terms of UV intensity?

A: Modern UV LED lamps like Sunlonge’s SL6300 series deliver 35,000 μW/cm² at 15 inches, matching or exceeding mercury lamp output while providing superior wavelength precision and stability.

Q: What is the typical lifespan of UV LED lamps?

A: Quality UV LED lamps offer 25,000-30,000 hours of operational life, which is 3-10 times longer than traditional mercury lamps. Sunlonge’s LEDs maintain >90% of initial intensity throughout this lifespan.

Q: Are UV LED lamps suitable for aerospace applications?

A: Yes, Sunlonge manufactures aerospace-certified UV LED lamps that meet Rolls-Royce RRES 90061 requirements and comply with all relevant ASTM standards for aviation NDT applications.

Q: What are the safety advantages of UV LED technology?

A: UV LEDs eliminate mercury exposure risks, reduce heat generation, produce no ozone, and enable instant on/off operation, creating significantly safer working environments compared to traditional UV lamps.

Q: How quickly do UV LED lamps start up compared to mercury lamps?

A: UV LEDs provide instant startup with full intensity immediately upon activation, while mercury lamps require 30 seconds to 2 minutes warm-up time

Q: What maintenance is required for UV LED lamps?

A: UV LED lamps require minimal maintenance due to their solid-state design and long lifespan. Unlike mercury lamps that need regular bulb replacement, UV LEDs typically operate maintenance-free for years.

Q: Can UV LED lamps operate on battery power?

A: Yes, Sunlonge’s portable UV LED lamps feature high-capacity lithium batteries providing 2.5 hours of continuous operation, making them ideal for field inspections and remote applications.

Industry Applications Table

| Industry | Application | Sunlonge Model | Key Benefits |

| Aerospace | Component crack detection | SL6300-AR | RRES 90061 certified, 3,500 μW/cm² |

| Automotive | Leak detection systems | SL6300-S | 35,000 μW/cm² intensity, portable |

| Oil & Gas | Pipeline inspection | SL8104-H | 21,000 μW/cm², rugged design |

| Electronics | PCB inspection | SL8103 | Wireless operation, compact size |

| Power Generation | Turbine blade testing | SL8604 | High penetration, adjustable focus |

Conclusion

The UV LED revolution is transforming industrial inspection and curing applications worldwide, with the market experiencing exceptional 24.6% annual growth driven by superior technology and compelling economic advantages. Sunlonge’s UV LED lamps represent the pinnacle of this technological advancement, offering industry-leading performance, comprehensive certifications, and innovative features that deliver measurable value across diverse applications.

With 25+ years of UV expertise, cutting-edge NICHIA LED technology, and rigorous quality standards, Sunlonge has established itself as the preferred supplier for organizations demanding the highest levels of performance and reliability. The compelling combination of 60-70% energy savings, 30,000-hour lifespan, and instant startup capability makes UV LED technology the clear choice for forward-thinking companies seeking competitive advantages through advanced inspection and curing solutions.

As industries continue embracing sustainable, efficient technologies, UV LED lamps from Sunlonge provide the performance, reliability, and economic benefits necessary to excel in today’s demanding industrial environment. The future of UV lighting is here, and it shines brightest through LED innovation.

CN

CN