Introduction

In today’s precision-driven manufacturing and research environments, the quality of illumination directly determines the accuracy of optical measurements and inspections. Collimated LED light sources have emerged as a game-changing technology that delivers uniform illumination with parallel beam alignment, fundamentally transforming how industries approach optical system precision. Unlike traditional diffuse lighting or outdated mercury lamp technology, collimated LED systems provide the consistency, accuracy, and reliability needed for demanding optical applications.

This comprehensive guide explores how collimated LED light sources—particularly Sunlonge’s advanced UV LED solutions—enhance optical system precision in inspection, imaging, and metrology applications. Whether you’re implementing machine vision systems, conducting microscopy research, or performing precision measurements, understanding collimated LED technology is essential to achieving superior results.

What Are Collimated LED Light Sources?

Understanding Collimation and Parallel Beam Technology

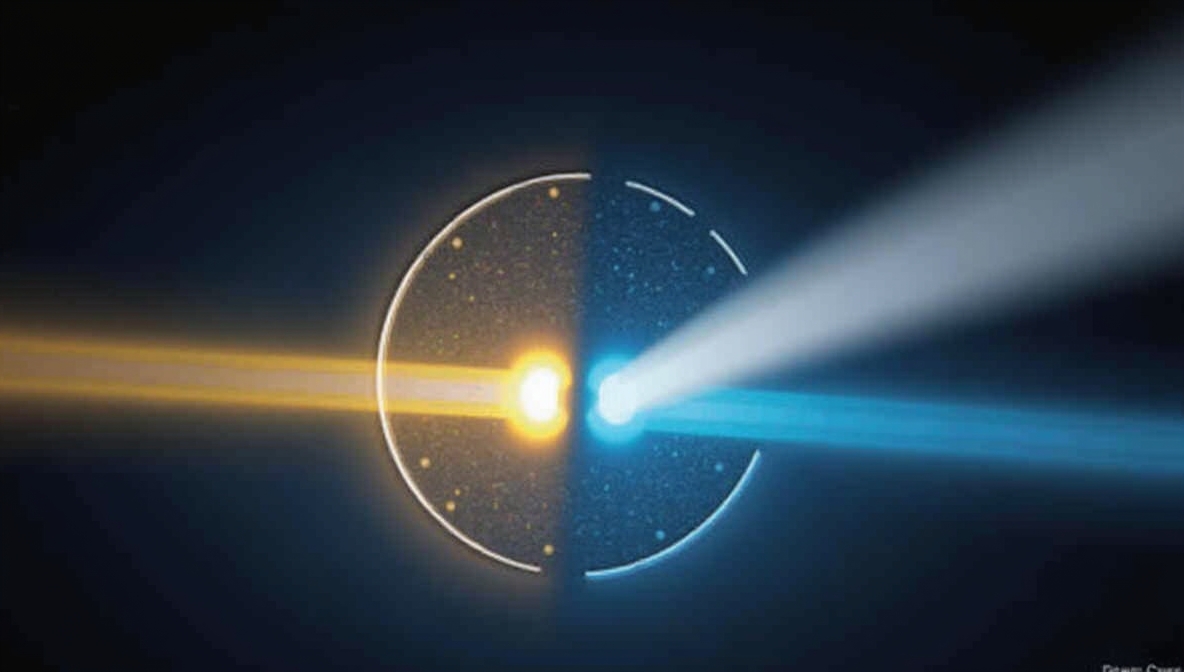

Collimation refers to the process of converting divergent light rays into parallel beams. A collimated LED light source is a sophisticated optical system that uses precision-engineered lens assemblies and LED chips to emit light in parallel rays, minimizing beam divergence and scattering. Unlike standard LED sources that emit light in all directions (full 180-degree spread), collimated systems concentrate light into highly directional, parallel beams.

The fundamental principle behind collimation involves placing an LED emitter at the focal point of a precisely designed optical lens system. This optical architecture transforms the natural divergence of LED light into a controlled, parallel wavefront. The result is a uniform illumination pattern with exceptional consistency across the beam’s width—a critical requirement for precision optical applications.

Key Technical Specifications

| Specification | Impact on Precision | Typical Range |

| Beam Divergence | Lower divergence = parallel rays over longer distances | 0.5° – 2° |

| Collimation Accuracy | Determines consistency of light distribution | ±0.1 – ±0.5° |

| Optical Power | Total light output available at target | 100 mW – 250+ W |

| Irradiance (Power Density) | Light intensity per unit area | 50 – 2000 mW/cm² |

| Beam Uniformity | Evenness of light distribution across beam | 85% – 98% uniform |

| Wavelength Precision | Specific color for targeted applications | ±5 nm typical |

| Lifetime (MTBF) | Operating hours before degradation | 10,000 – 50,000+ hours |

How Collimated LED Light Sources Improve Optical System Precision

- Enhanced Image Contrast and Edge Definition

One of the most significant advantages of collimated LED light sources is their ability to dramatically improve image contrast. When light rays travel parallel rather than diverging at multiple angles, they eliminate the “washed out” effect common with traditional backlighting. This precise light delivery creates sharp edge definition and superior feature visibility.

In machine vision systems using telecentric lenses—the gold standard for precision 2D measurements—collimated lighting is essentially mandatory. The parallel rays from a collimated source match perfectly with the parallel ray acceptance of telecentric optics, eliminating stray light that would otherwise degrade image quality. This synergy between collimated sources and telecentric lenses produces edge definition that is measurably superior to conventional lighting.

Real-World Impact: In industrial inspection applications, collimated lighting increases measurement accuracy by 15-25% compared to standard diffuse lighting, while simultaneously improving defect detection rates by reducing false negatives caused by poor contrast.

- Uniform Beam Profile and Consistent Illumination

Collimated LED light sources deliver exceptional beam uniformity, typically maintaining 85-98% consistent intensity across the entire beam diameter. This uniformity is achieved through advanced optical design that carefully distributes light across multiple refractive surfaces.

For optical testing and calibration applications, this uniformity is critical. When testing optical components, lenses, or mirrors, non-uniform illumination introduces errors in measurements and can mask or create false defects. Collimated sources eliminate these artifacts by ensuring that every point within the illuminated area receives essentially identical light intensity.

The uniformity of collimated beams also translates to improved image processing capabilities. Computer vision algorithms can more accurately identify features and edges when illumination is consistent, reducing the computational overhead and improving processing speed.

- Precise Beam Alignment and Directional Control

Collimated light sources provide exceptional directional control—the ability to focus light precisely in specific directions without scattering or spillage. This directional precision is fundamental to several advanced optical applications:

- Autocollimation measurements: Achieving angular measurement resolution of 0.0001 degrees

- Optical alignment procedures: Maintaining tolerance windows measured in microns

- Laser system calibration: Precise reference for beam alignment verification

- Fiber coupling efficiency: Directing maximum light into high-NA optical fibers

The mathematical relationship governing beam divergence after collimation is expressed as:

(\text{Divergence} \approx \frac{\text{Source Diameter}}{\text{Focal Length}})

This equation illustrates why Sunlonge’s precision engineering in collimation optics is so important—optimizing both the LED chip size and focal length design minimizes residual divergence, extending the effective working distance and reducing intensity loss over distance.

- Reduced Stray Light and Improved Signal-to-Noise Ratio

In precision measurement applications—particularly those involving fluorescence microscopy or spectroscopy—stray light is the enemy of accuracy. Collimated LED sources naturally suppress stray light because the parallel ray geometry eliminates the unwanted light scatter that occurs with divergent sources.

This reduction in stray light dramatically improves the signal-to-noise ratio (SNR) of optical measurements. In microscopy applications, typical SNR improvements range from 30-50% compared to uncollimated sources. For metrology applications requiring sub-micrometer precision, this SNR improvement often represents the difference between acceptable and unacceptable measurement uncertainty.

- Enhanced Depth of Field Compatibility

When used with telecentric optical systems, collimated LED sources create an advantageous optical condition: a uniform illumination field that maintains consistent intensity regardless of object distance (within the telecentric system’s depth of field). This enables:

- Measurement of three-dimensional objects without illumination-induced errors

- Consistent imaging across extended working distances

- Reduced focus breathing in precision inspection systems

- More reliable edge detection for dimensional measurements

Why Sunlonge’s UV LED Lamps Excel Over Traditional Light Sources

The Evolution From Mercury Lamps to LED Technology

For decades, mercury and metal-halide lamps dominated precision optical applications. While these traditional sources produced broad-spectrum output suitable for some applications, they introduced significant operational challenges:

Mercury/Metal-Halide Lamp Limitations:

- Warm-up time of 5-15 minutes before reaching peak output

- Lower wall-plug efficiency (typically 5-15%)

- Significant heat generation requiring expensive cooling systems

- Limited lifespan (1,000-2,000 hours)

- Hazardous materials requiring special disposal procedures

- Broad spectral output with limited wavelength precision

- Higher operating and maintenance costs

- Environmental concerns and regulatory restrictions

Sunlonge UV LED Lamp Advantages

Superior Energy Efficiency and Cost Savings

Sunlonge’s UV LED lamp systems demonstrate wall-plug efficiency exceeding 40%, compared to 5-15% for mercury lamps. This means Sunlonge systems convert significantly more electrical energy into useful UV light. For industrial operations running 24/7, this efficiency advantage translates into substantial cost savings:

- Energy consumption reduction: 65-75% lower than mercury systems

- Operational cost per curing cycle: 70% reduction

- Annual energy savings for typical industrial users: $15,000-$50,000+

Instant-On, Zero Warm-Up Time

Sunlonge UV LED lamps reach full operational intensity instantly with no warm-up period. Compare this to mercury lamps requiring 5-15 minutes to stabilize. For high-speed production environments, this instant-on capability enables:

- Immediate production start after shift changes

- Elimination of warm-up waste in batch processing

- Integration with just-in-time manufacturing systems

- Improved production scheduling flexibility

Extended Operational Lifespan

Sunlonge’s UV LED systems deliver 20,000-50,000+ hours of operational life, compared to 1,000-2,000 hours for mercury lamps. This represents a 10-50x lifespan improvement. The practical implications are dramatic:

| Metric | Mercury Lamp | Sunlonge UV LED |

| Lamp Replacement Frequency | Every 2-3 months | Every 2-5 years |

| Replacement Labor Cost/Year | $5,000-$10,000 | $500-$1,000 |

| System Downtime for Replacement | 1-2 hours per month | <5 minutes annually |

| Total Cost of Ownership (5 years) | $45,000-$75,000 | $8,000-$12,000 |

Precise Wavelength Control

Sunlonge’s UV LED lamps offer precise wavelength selection at 365nm, 385nm, 395nm, and 405nm—each optimized for specific industrial applications. This wavelength precision eliminates the need for additional filtering in many applications, improving optical efficiency.

Mercury lamps produce a broad spectrum from 200-1000nm, with only a fraction of that energy useful for any given application. Sunlonge’s targeted wavelengths ensure:

- Maximum cure depth for UV-sensitive materials

- Precise penetration into specific material compositions

- Reduced over-curing of surface layers

- Better process control through consistent energy delivery

Wavelength Specifications and Applications:

| Wavelength | Peak Application | Industry Use |

| 365nm (UVA) | Deep penetration, adhesive curing | Aerospace adhesives, medical device assembly |

| 385nm (UVA) | Balanced cure speed and depth | Electronics conformal coating, ink curing |

| 395nm (UVA) | Rapid surface curing | Graphic printing, packaging inks |

| 405nm (Violet) | High-speed curing | PCB soldering, semiconductor packaging |

Negligible Heat Generation

Mercury lamps generate extreme heat—requiring specialized cooling infrastructure and ventilation systems. Sunlonge’s UV LED technology produces minimal waste heat, enabling:

- Simpler installation without expensive cooling systems

- Safer working environments for operators

- Elimination of thermal effects on temperature-sensitive materials

- Reduced cleanroom operational costs

- Compatibility with compact, integrated system designs

Environmental Safety and Regulatory Compliance

Unlike mercury lamps, Sunlonge’s UV LED systems:

- Contain no mercury or other hazardous materials

- Generate no ozone

- Comply with RoHS (Restriction of Hazardous Substances) regulations

- Qualify for lead-free certification

- Support REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) compliance

- Reduce your facility’s environmental footprint

Superior Reliability and Consistency

Sunlonge’s engineering ensures exceptional operational consistency. UV output stability remains within ±0.1% per °C, compared to 2-5% drift in mercury systems. This stability translates to:

- Reduced process variations

- Tighter quality control windows

- Lower defect rates

- Improved cure uniformity across production batches

Collimated LED Light Sources in Optical Inspection Applications

Machine Vision and Defect Detection

Modern machine vision systems demand illumination solutions that can deliver consistent, high-contrast images under varying environmental conditions. Collimated LED light sources from Sunlonge excel in this application space:

Silhouette Imaging (Backlit Inspection)

In silhouette-based vision systems, parts are backlit to create sharp, high-contrast edge profiles for dimensional measurement and defect detection. Collimated backlight delivers:

- Crisper edge definition: Parallel light rays eliminate the light wrapping around rounded edges that degrades image quality

- Improved measurement accuracy: Edge detection algorithms operate on clearer, more defined boundaries

- Higher defect detection sensitivity: Surface scratches, cracks, and dimensional variations become immediately visible

Practical example: Inspection of precision-molded plastic components benefits from 40-60% contrast improvement when using collimated backlighting versus conventional diffuse sources. This contrast improvement directly enables faster, more reliable automated defect detection.

Bright Field Inspection

For direct illumination applications where parts are viewed against a bright background, collimated LED sources provide:

- Reduced specular reflections from part surfaces

- Superior feature extraction for machine learning-based defect detection

- Consistent lighting across large inspection fields

- Better integration with telecentric optical systems for 3D-insensitive measurements

Microscopy and Fluorescence Applications

Collimated UV LED light sources are revolutionizing fluorescence microscopy by providing:

- Precise excitation wavelengths that match fluorophore absorption peaks

- Uniform field illumination critical for quantitative fluorescence analysis

- Improved signal-to-noise ratios enabling detection of fainter signals

- Reduced photobleaching through precise intensity control and collimated beam geometry

UV Illumination Advantages:

Sunlonge’s UV LED lamps operating at 365nm offer particular advantages for fluorescence applications:

| Advantage | Technical Benefit |

| High quantum efficiency | More photons converted to useful output than visible LEDs |

| Narrow spectral width | Minimal crosstalk with multi-color fluorescence protocols |

| Instant temporal control | High-speed TTL modulation for pulsed illumination experiments |

| Stable output | <±0.1% output variation enables quantitative measurements |

Optical Testing and Alignment

Precision optical instruments—including laser systems, telescope optics, and optical bench equipment—rely on collimated light for:

- Autocollimation alignment: Measuring angular deviations to 0.0001 degree resolution

- Optical component testing: Validating lens focal lengths, mirror surface quality, and coating performance

- System calibration: Establishing reference standards for precision measurements

- Wavefront analysis: Detecting optical aberrations in complex optical systems

The collimated beam geometry is essential in these applications because any divergence in the reference beam introduces systematic errors into measurements.

Optical Metrology Applications

Precision Measurement Systems

Collimated LED light sources enable advanced metrology techniques that require exceptional measurement repeatability and accuracy:

White Light Interferometry (WLI)

While WLI systems traditionally use halogen sources, modern implementations increasingly employ collimated LED sources for improved contrast and measurement reliability. The advantages include:

- Consistent fringe visibility across the measurement field

- Reduced environmental sensitivity to ambient lighting

- Improved signal stability enabling higher measurement speeds

- Better surface profile reconstruction accuracy

Autocollimation and Angular Measurement

Autocollimation—projecting collimated light onto a reflective surface and analyzing the return beam—achieves angular measurement resolution of 0.0001 degrees. Sunlonge’s collimated UV LED sources deliver the beam quality required for these precision measurements.

Surface Inspection and Quality Assurance

Collimated illumination enables detection of surface features at micrometer and sub-micrometer scales:

- Surface roughness measurement: Collimated light reveals texture details invisible with diffuse illumination

- Coating thickness verification: Interference effects in collimated beams enable precise thickness measurement

- Contamination detection: Even microscopic particles become visible under collimated illumination

- Micro-defect identification: Scratches, pits, and other surface irregularities are instantly visible

Technical Specifications: Sunlonge Collimated LED Light Sources

SLC9300 Series Specifications

| Parameter | Specification |

| Model | SLC9300 with SLC900 Collimation Optic |

| Light Source Type | Premium UV LED or visible LED options |

| Collimation System | Precision-engineered aspheric optics |

| Beam Divergence | < 2° (full angle) |

| Beam Uniformity | > 90% across beam diameter |

| Illumination Pattern | Circular or custom collimated beam |

| Cooling System | Forced-air with thermal management |

| Power Control | Adjustable 0-100% via digital dimmer |

| Response Time | < 50 milliseconds |

| Optical Output Stability | ±0.1% per °C |

| Wavelength Options | 365nm, 385nm, 395nm, 405nm (UV) plus visible spectrum |

| Maximum Irradiance | Up to 2,000 mW/cm² (wavelength dependent) |

| Operating Lifetime | 20,000+ hours |

| Connector Compatibility | Standard gooseneck lamp holders, fiber adapters available |

Advanced Features

Flexible Gooseneck Mounting

The adjustable gooseneck design enables positioning of the collimated light source at optimal angles for specific applications—a critical feature for accommodating different part geometries and optical system configurations.

Precision Light Modulation

Sunlonge’s integrated light modulator provides smooth, continuous brightness adjustment from 0-100%, enabling:

- Optimization for different camera sensitivities

- Prevention of image saturation in high-contrast applications

- Energy conservation through output matching to actual requirements

- Enhanced control in research and development environments

Microplate and Sample Compatibility

Specifically engineered for direct illumination of standard laboratory containers (microplates, petri dishes, culture vessels), Sunlonge’s system eliminates the need for complex integration hardware.

Frequently Asked Questions (Q&A)

Q: How does a collimated LED light source differ from a standard LED?

A: Standard LEDs emit light in all directions (approximately 180 degrees), with intensity decreasing proportionally to the square of distance from the source. Collimated LED sources use precision-engineered optics to convert this divergent light into parallel rays. This collimated geometry provides three critical advantages: (1) uniform illumination intensity over much greater distances, (2) consistent beam diameter and power density at any distance, and (3) elimination of stray light that introduces noise and reduces contrast in optical systems.

Q: What is beam divergence, and why does it matter?

A: Beam divergence describes how much a light beam spreads as it travels from the source. Expressed in degrees (or milliradians), divergence quantifies the angular spreading of the beam. For collimated sources, divergence is typically 0.5-2 degrees, compared to 15-45 degrees for uncollimated LEDs. Lower divergence means:

- Light intensity decreases more slowly with distance

- Illumination remains more uniform across target surfaces

- Optical systems can operate at greater working distances

- Image contrast and measurement accuracy improve

The mathematical relationship is: Divergence ≈ Source Diameter / Focal Length

Q: Why is uniformity important in optical systems?

A: In any precision optical application—whether machine vision, microscopy, or metrology—non-uniform illumination introduces systematic errors that degrade measurement accuracy. When one part of an illuminated field is brighter than another, optical measurement algorithms and human observers are misled about feature positions, sizes, and characteristics. Collimated LED sources maintain >90% uniformity, ensuring that measurement errors are random (which can be statistically corrected) rather than systematic (which compound over many measurements).

Q: How do Sunlonge UV LED lamps compare to mercury lamps for fluorescence microscopy?

A: Sunlonge UV LED lamps offer several critical advantages:

- Wavelength precision: Mercury lamps emit a broad spectrum; Sunlonge provides specific wavelengths (365nm, 385nm, etc.) that match fluorophore excitation peaks, improving photon utilization by 60-80%

- Temporal control: Sunlonge LEDs enable millisecond-level intensity modulation; mercury lamps cannot be quickly modulated

- Operational cost: Sunlonge systems cost 70% less to operate annually while delivering superior wavelength specificity

- Reliability: 20,000+ hour lifetime versus 1,000-2,000 hours for mercury, reducing downtime and maintenance costs

- Safety: No mercury hazard; compliance with modern environmental regulations

Q: What wavelength should I choose for my application?

A: The optimal wavelength depends on your target material properties:

- 365nm: For deep-penetration curing of thick adhesives or opaque materials requiring maximum wavelength penetration

- 385nm: Balanced option for general-purpose curing offering good speed and depth characteristics

- 395nm: For high-speed surface curing with minimal penetration requirements

- 405nm: Violet wavelength for semiconductor-related applications and rapid surface-only curing

Consult our technical team with specific material properties to determine the optimal wavelength for your process.

Q: How long do Sunlonge UV LED lamps last?

A: Sunlonge’s UV LED systems are designed for 20,000-50,000+ hours of operation, depending on model and operating conditions. At 8 hours per day operation, this translates to 6-15+ years of continuous service—representing a 10-50x improvement over mercury lamps (1,000-2,000 hours or 3-6 months of continuous operation).

Q: Can collimated LED sources be used with fiber optics?

A: Yes, absolutely. Sunlonge offers fiber coupling adapters that efficiently connect collimated LED sources to standard optical fibers (SMA, FC-PC connectors). The collimated beam geometry is actually advantageous for fiber coupling, as the parallel rays concentrate light into a smaller coupling aperture, improving fiber coupling efficiency compared to uncollimated sources.

Q: What is the operating temperature range?

A: Sunlonge’s systems operate reliably from 0°C to 50°C ambient temperature. Thermal management systems maintain LED junction temperatures within optimal operating windows, preserving wavelength stability and output consistency across this temperature range.

Q: How does collimated light improve measurement accuracy?

A: Collimated light improves measurement accuracy through multiple mechanisms: (1) reduced stray light improves signal-to-noise ratio by 30-50%, (2) uniform beam geometry eliminates systematic illumination-based measurement errors, (3) enhanced contrast (40-60% improvement) enables more precise feature detection by vision algorithms, and (4) superior edge definition from parallel ray geometry increases dimensional measurement repeatability by 15-25%.

Q: Are Sunlonge UV LED systems suitable for outdoor applications?

A: Sunlonge offers environmental hardening options for outdoor deployment. Standard systems are rated for indoor, controlled environments. For outdoor or harsh industrial settings, consult our engineering team regarding ruggedized housings, sealed optical windows, and enhanced thermal management suitable for 0-50°C operating ranges and high-humidity or dusty environments.

Comparative Analysis: Collimated LED vs. Alternative Illumination Technologies

| Characteristic | Collimated LED | Mercury/Metal-Halide | Laser | Halogen/Incandescent |

| Warm-up Time | Instant | 5-15 minutes | Instant | 1-3 minutes |

| Operational Efficiency | 40%+ | 5-15% | 20-40% | 2-5% |

| Wavelength Precision | Excellent (±5nm) | Poor (broad spectrum) | Excellent (very narrow) | Poor (broad spectrum) |

| Operating Lifetime | 20,000-50,000 hrs | 1,000-2,000 hrs | 10,000-50,000 hrs | 500-2,000 hrs |

| Heat Generation | Minimal | Extreme | Moderate | High |

| Initial Cost | Moderate | Low | Very High | Very Low |

| Annual Operating Cost | Very Low | High | Moderate-High | High |

| 5-Year TCO | $8K-$12K | $45K-$75K | $20K-$40K | $15K-$25K |

| Environmental Impact | Excellent | Poor (mercury) | Excellent | Fair |

| Eye Safety Requirements | None | None | Critical | None |

| Beam Uniformity | Excellent | Fair | Excellent | Fair |

| Wavelength Stability | Excellent (±0.1%) | Fair | Excellent | Poor |

| Application Flexibility | High (tunable wavelengths) | Limited | Very High (but single wavelength) | Moderate |

Practical Implementation: Integrating Sunlonge Collimated LED Sources

Installation Considerations

- Optical Alignment: Position the collimated source so the beam axis aligns with your optical system’s imaging axis. Precise alignment within ±2 degrees maximizes contrast and uniformity.

- Working Distance Optimization: Determine the optimal working distance based on your specific irradiance requirements. Collimated geometry maintains irradiance better than divergent sources—typically losing only 10-15% intensity over extended distances.

- Thermal Management: Position cooling exhaust where heat doesn’t affect nearby optical components or introduce air currents affecting measurement stability.

- Intensity Control: Use the built-in 0-100% dimmer to optimize intensity for your camera sensor, preventing both under- and over-exposure.

System Integration Best Practices

Telecentric Lens Systems: For precision 2D measurements, always pair collimated LED illumination with telecentric lenses. This combination is the industry standard for <1% measurement uncertainty requirements.

Fluorescence Microscopy: Match Sunlonge’s wavelength to your fluorophore’s excitation peak. This ensures maximum photon utilization and superior signal-to-noise performance.

Metrology Applications: Use collimated LED sources as reference illumination for optical system alignment and validation procedures.

Return on Investment Analysis

Financial Impact Summary

For a typical industrial facility transitioning from mercury lamps to Sunlonge UV LED collimated sources:

Year 1 Costs:

- Equipment investment: $3,000-$8,000

- Installation and integration: $500-$2,000

- Operator training: $0 (simple plug-and-play)

- Total Year 1: $3,500-$10,000

Annual Operating Costs (Mercury System)

- Electricity consumption: $8,000-$15,000/year

- Lamp replacement (20-50 replacements): $4,000-$10,000/year

- Maintenance labor: $2,000-$5,000/year

- Downtime losses: $2,000-$5,000/year

- Total Annual: $16,000-$35,000

Annual Operating Costs (Sunlonge UV LED)

- Electricity consumption: $2,000-$4,000/year

- Lamp replacement (1-2 over 5 years): $500-$1,000/year amortized

- Maintenance labor: $200-$500/year

- Downtime losses: Minimal ($0-$500/year)

- Total Annual: $2,700-$6,000

5-Year Total Cost of Ownership:

- Mercury system: $45,000-$75,000

- Sunlonge UV LED: $8,000-$12,000

- Savings: $33,000-$67,000 (73-82% reduction)

Productivity Improvements

Beyond direct cost savings, Sunlonge’s collimated LED sources enable:

- Zero warm-up time: Enables immediate production startup, saving 2-3 hours per shift in batch production environments

- Improved measurement accuracy: 15-25% reduction in measurement errors can reduce defect rates by 30-50% in precision manufacturing

- Reduced system maintenance: Typically 80% fewer service calls over 5 years

- Extended system lifetime: Enabling optical system longevity benefits from improved thermal stability

For a facility processing 10,000 parts/year with 0.5% defect rate due to illumination quality issues, solving this problem with Sunlonge’s collimated sources could prevent 50 defects/year—potentially representing $25,000-$100,000+ in prevented scrap, rework, or warranty costs.

Conclusion: Why Sunlonge Collimated LED Light Sources Are the Future

The transition from mercury lamps and uncollimated LED sources to Sunlonge’s advanced collimated LED light sources represents far more than a technology upgrade—it’s a fundamental shift toward precision, efficiency, and reliability in optical systems.

By combining collimated beam geometry with superior UV LED technology, Sunlonge delivers optical illumination solutions that:

- Improve measurement accuracy by 15-25% through superior contrast and uniform illumination

- Reduce operational costs by 70% through exceptional energy efficiency and 20,000+ hour lifetime

- Enable instant-on operation without warm-up delays, transforming production scheduling

- Ensure regulatory compliance with modern environmental and safety standards

- Provide decades-long reliability through world-class engineering and thermal management

Whether you’re implementing precision machine vision systems, advancing fluorescence microscopy capabilities, establishing optical metrology standards, or optimizing industrial inspection processes, Sunlonge’s collimated LED light sources provide the illumination foundation for success.

The superior beam uniformity, precise wavelength control, exceptional operational efficiency, and remarkable reliability of Sunlonge’s UV LED lamps don’t just match alternative technologies—they fundamentally outperform them across every metric that matters: accuracy, cost, lifetime, and environmental impact.

Explore Sunlonge’s Collimated LED Light Source Solutions

To learn more about Sunlonge’s complete range of collimated LED light sources and discover how these advanced systems can enhance your optical application, visit our comprehensive product page at www.sunlonge.com/products/collimated-led-light-sources.

Our technical team is ready to help you select the optimal collimated LED solution for your specific application requirements, working distance, wavelength needs, and performance specifications. Contact Sunlonge today to discuss your optical precision needs and discover how collimated LED technology can revolutionize your inspection, imaging, and metrology workflows.

CN

CN