Introduction

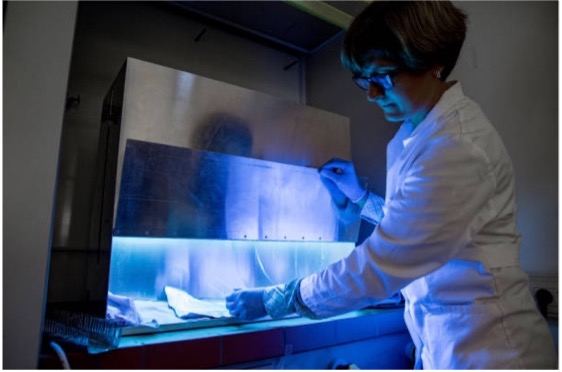

Under the rapid advancement of technology, diverse measures and applications have arisen to provide solutions to various problems. Among all these devices, the UV inspection lamp is often perceived as low-tech compared with the more complex techniques. However, there must be a reason that it has survived in the market for a long time and has not been replaced by any high-tech substitutes. It is even expected to grow at a compound annual growth rate of 11.2% from 2022 to 2023. In fact, UV inspection lamps are typically divided into two types: magnetic particle inspection (MPI) and fluorescent penetrant inspection (FPI), despite sharing the same characteristic of using ultraviolet light during the inspection process.

Differences between Magnetic Particle Inspection (MPI) and Fluorescent Penetrant Inspection (FPI)

The decision of which inspection to apply is commonly made by Level III-certified personnel at the facility. Fortunately, most of the time, the huge variance between these two techniques clearly directs the decision to either one.

- Purposes of inspection – Considering the different requirements and characteristics of different types of inspection, the purposes of the inspection are a critical factor in determining the type of technique. In particular, magnetic particle inspection serves as an ideal NDT method for detecting inclusions. Inclusions, the pieces of metal that are not homogenized with the metal of other parts of the shell of the casting mold, can be extremely harmful as they can lead to a crack during the service life of the products. On the other hand, fluorescent particle inspection is perfect for detecting shrinkage and porosity.

- Materials of inspection – Similar to the above factor, different materials carry different properties, which create a variance in the most suitable technique to apply. As implied by its name, magnetic particle inspection can only deal with alloys or metals that can be magnetized, for instance, steel. The inspection is completed on both the surface and subsurface. Meanwhile, fluorescent penetrant inspection can be applied to any material with a non-porous surface. Since porous materials tend to hold the penetrant in the non-defect areas, the actual defects cannot be highlighted. Accordingly, in view of the different materials required to undergo inspection, the technique applied should be carefully chosen.

Capabilities of UV Inspection Lamps

After realizing the differences between the two types of inspection techniques, discussing the capabilities of the UV inspection lamps allows an even deeper understanding of their development. The greatest strength of UV inspection lamps is their ability to generate a detailed inspection. Taking the SL6300-UV Adjustable Light Beam UV LED Flashlight from Sunlonge as an instance, it features a powerful UV-A LED light with a wavelength of 365 nm. Its high intensity is ideal for fluorescent magnetic particle and penetrant testing, mining inspection, and a variety of other specialized applications. In addition, it is equipped with a convenient design that allows hands-free operation. The installation of the headlamp also provides ease of adjustment of the focal length. However, despite the countless advantages of UV inspection lamps, there are still several limitations. Since UV light is designed to detect all defects, it is not the solution to all problems. Specifically, UV light cannot be applied to identify defects in a large area. Furthermore, certain materials, for example, dents, are not illuminated under UV light. Therefore, UV inspection lampsare not perfect in all circumstances. However, they are still ideal for numerous applications, ranging from steel gears, engine blocks, connecting rods, and aluminium brackets.

Conclusion

Thanks to the booming technical improvement, the invention of UV inspection lamps has brought plenty of benefits to the modern world. Despite being described as a relatively low-tech product, UV light has been on the market for a long history of time without being eliminated. By learning more about the differences between its two common techniques of inspection, magnetic particle inspection, and fluorescent penetrant inspection, it is much easier to determine which method to apply according to the purposes and materials of inspection. On top of the differences, identifying the abilities and limitations of UV inspection lamps allows users to maximize their effectiveness. All in all, UV inspection lamps are great tools with diverse applications in various fields.

CN

CN