In industries like aerospace, automotive, and manufacturing, ensuring the integrity of materials without causing damage is a top priority. That’s where Non-Destructive Testing (NDT) comes in, and one of its most powerful tools is the UV NDT lamp. At the heart of this technology is the excitation light source, a critical component that activates fluorescent dyes to reveal hidden flaws. Whether you’re new to NDT or looking to refine your process, this beginner-friendly guide will explain what excitation light sources are, how they work, and why they’re vital for scientific and industrial applications. Plus, we’ll provide a practical checklist to confirm your UV NDT lamp is ready before every use, ensuring safety and accuracy.

Sunlonge, a trusted name in LED lamp technology, offers high-performance UV NDT lamps like the SL8104 UV LED Lamp, designed to meet rigorous inspection needs. Let’s dive in!

What is an Excitation Light Source?

An excitation light source is a specialized light that energizes fluorescent molecules, causing them to glow. Imagine it as a magic wand that makes invisible details visible under specific conditions. In technical terms, it emits light at a precise wavelength—often ultraviolet (UV) or visible light—to “excite” fluorescent dyes or materials. When these molecules absorb the light, they emit a different color, illuminating cracks, leaks, or structures that would otherwise stay hidden.

In scientific research, excitation light sources power tools like fluorescence microscopes to study cells. In industrial settings, they’re the backbone of UV NDT lamps, helping inspectors detect surface defects in materials without breaking them apart.

How Do Excitation Light Sources Work?

The science behind an excitation light source is both fascinating and straightforward. It’s all about fluorescence—a process where light energy transforms into a visible glow. Here’s how it works in simple steps:

- Light Emission: The excitation light source (e.g., a UV-A LED at 365 nm) shines on a fluorescent dye or material.

- Energy Absorption: The dye absorbs this light, pushing its molecules into an “excited” high-energy state.

- Light Release: As the molecules relax back to their normal state, they release energy as light—usually a brighter, different color than the original source.

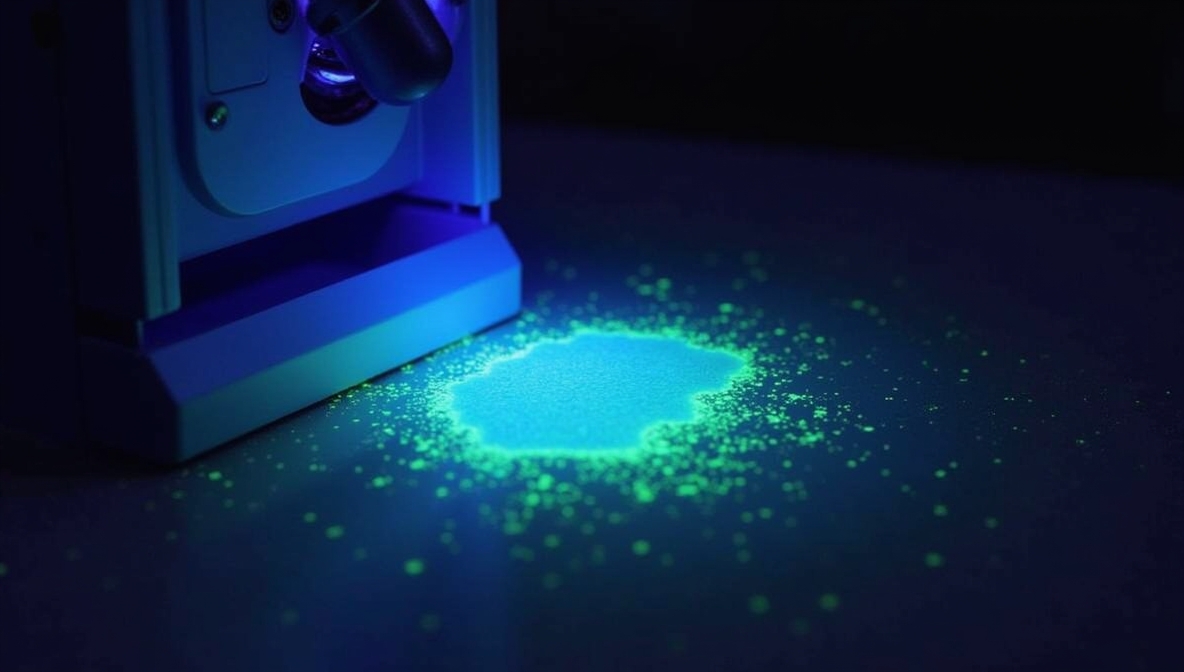

This glowing effect is what makes excitation light sources so valuable. In NDT, for example, a UV lamp’s excitation light reveals defects as glowing spots against a dark background, making them easy to spot. According to Evident Scientific, selecting the right wavelength is key to maximizing this fluorescence effect.

Why Are Excitation Light Sources Critical in UV NDT?

UV NDT lamps rely on excitation light sources to activate fluorescent dyes in methods like Magnetic Particle Inspection (MPI) and Dye Penetrant Inspection (DPI). These techniques are essential for industries that demand precision and safety. Here’s why they matter:

- Non-Invasive Detection: They find defects without altering the material, preserving its integrity.

- High Sensitivity: Fluorescent dyes, when excited, can reveal cracks as small as 0.001 inches, per the American Society for Nondestructive Testing (ASNT).

- Efficiency: LED-based UV lamps, like those from Sunlonge, offer instant-on functionality and long lifespans—up to 30,000 hours—reducing downtime and costs.

In short, the excitation light source is the engine that drives these inspections, ensuring quality and reliability in critical applications.

UV NDT Lamp Inspection Checklist: What to Confirm Before Every Use

To get the most out of your UV NDT lamp’s excitation light source, you need to confirm it’s in top shape before every inspection. Here’s a beginner-friendly checklist to follow:

- Measure UV Intensity

- Use a UV meter to ensure the lamp delivers at least 1,000 µW/cm² at 15 inches (38 cm), the minimum for most NDT standards. Sunlonge’s SL8104, for instance, achieves up to 5,000 µW/cm², exceeding expectations.

- Verify Wavelength

- Check that the lamp emits UV-A light at 365 nm, the ideal wavelength for exciting NDT fluorescent dyes. A mismatch here could weaken fluorescence.

- Assess Battery Life (If Portable)

- For cordless models like the SL8104, confirm the battery is charged for your inspection duration—up to 8 hours on a full charge.

- Clean the Lens and Housing

- Wipe away dust or grime that could block or scatter UV light, ensuring consistent illumination.

- Inspect for Damage

- Look for cracks, dents, or wear on the lamp body and lens. Damage could compromise safety or performance.

- Check Compliance with Standards

- Confirm the lamp meets specs like ASTM E3022 or ISO 3059, guaranteeing reliability. Sunlonge’s products are certified for these benchmarks.

- Test Additional Features

- If your lamp has a white light mode (like the SL8104), test it to ensure versatility during inspections.

Following this checklist ensures your excitation light source performs at its best, delivering accurate results every time.

Q&A: Answers to Beginner Questions

What’s the Difference Between UV-A and UV-B Light?

UV-A (315-400 nm) is safer and better suited for exciting fluorescent dyes in NDT, while UV-B (280-315 nm) is more harmful and rarely used in these applications.

How Often Should I Calibrate My UV NDT Lamp?

Calibration every 6 months is a good rule of thumb, but check your manufacturer’s guidelines or recalibrate after heavy use or damage.

Why Choose an LED UV Lamp Over a Mercury-Vapor One?

LED lamps, like Sunlonge’s SL8104, are more energy-efficient, durable (30,000+ hours vs. 2,000 hours for mercury-vapor), and don’t require warm-up time.

Can Any UV Light Work as an Excitation Light Source?

No, only lamps designed for NDT, with precise UV-A output and compliance with standards, should be used for safety and effectiveness.

Statistics and Figures: The Power of UV NDT

- Market Growth: The global NDT market is expected to hit $24.23 billion by 2025, with a 7.5% CAGR from 2020, driven by demand for reliable inspection methods (MarketsandMarkets).

- Defect Detection: Fluorescent penetrant testing, powered by excitation light sources, detects flaws as tiny as 0.001 inches, making it one of the most sensitive NDT techniques (ASNT).

- Efficiency Boost: LED UV lamps reduce energy use by up to 70% compared to traditional mercury-vapor lamps, per industry studies.

These numbers highlight why UV NDT lamps—and their excitation light sources—are indispensable tools today.

Table: Sunlonge SL8104 UV NDT Lamp Specifications

| Feature | Details |

| Wavelength | 365 nm (UV-A) |

| UV Intensity | Up to 5,000 µW/cm² at 15 inches |

| Battery Life | Up to 8 hours |

| Lifespan | 30,000+ hours |

| Standards Compliance | ASTM E3022, ISO 3059 |

| Extra Features | White light option, lightweight design |

The SL8104 exemplifies how a high-quality excitation light source can enhance NDT inspections.

Conclusion

Mastering the use of UV NDT lamps starts with understanding the power of the excitation light source. By activating fluorescent dyes, these sources reveal critical insights in scientific research and industrial quality control. With the checklist above, you can ensure your lamp is ready for every task, from checking intensity to confirming compliance. Sunlonge’s SL8104 UV LED Lamp combines cutting-edge technology with user-friendly design, making it an ideal choice for beginners and pros alike. Equip yourself with the right tools and knowledge, and you’ll be ready to tackle any inspection with confidence.

CN

CN