Introduction

The global shift toward advanced manufacturing technologies has positioned fiber-coupled laser sources as critical components in precision applications across multiple industries. As manufacturing processes demand greater accuracy, efficiency, and reliability, fiber-coupled laser sources systems have emerged as the preferred solution for applications requiring exceptional beam quality and flexible light delivery. These systems represent a fundamental advancement over traditional free-space laser configurations, offering unique advantages that make them indispensable in modern precision manufacturing environments.

Understanding Fiber-Coupled Laser Sources

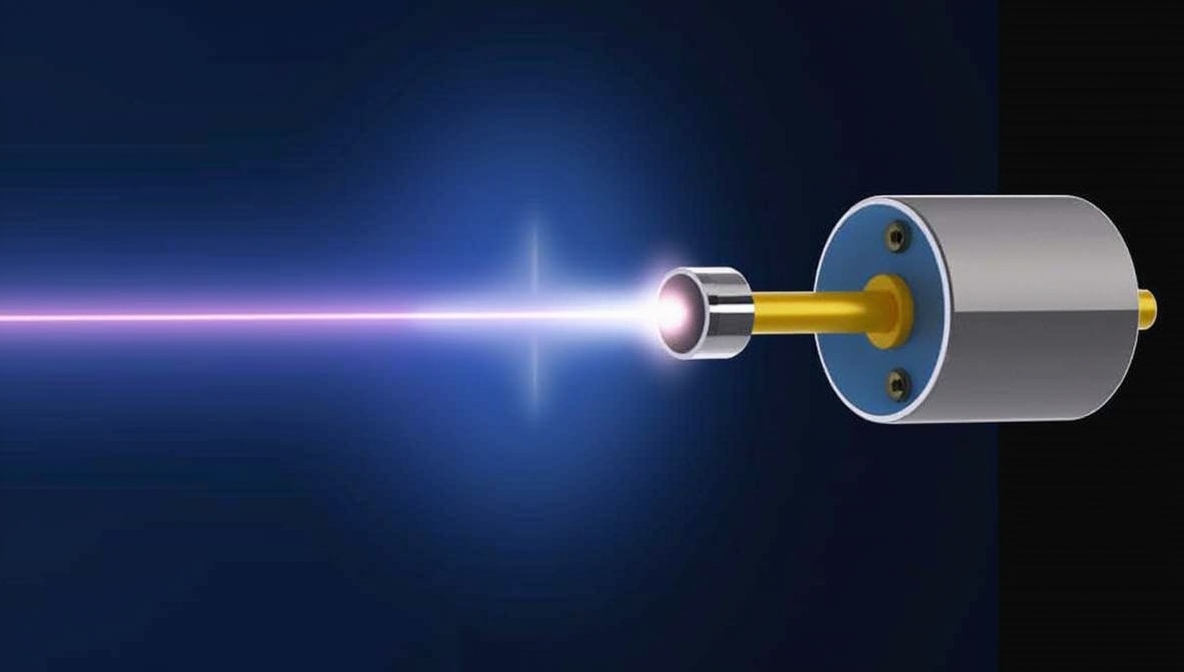

Fiber-coupled laser sources are sophisticated systems where the laser output is precisely coupled into an optical fiber, enabling controlled delivery of laser light to specific locations with exceptional accuracy. Unlike traditional free-space laser systems, these configurations integrate the laser diode or source with optical fiber technology to create a unified system that combines the power and coherence of laser light with the flexibility and precision of fiber-optic delivery.

The core principle involves focusing the laser beam into the optical fiber using specialized coupling optics, including lenses and mirrors, to ensure minimal power loss during the transfer process. This integration creates a system where the light emerging from the optical fiber maintains excellent beam characteristics while providing unprecedented flexibility in beam positioning and delivery.

Superior Beam Quality and Control

Enhanced Beam Characteristics

One of the most significant advantages of fiber-coupled laser sources is their superior beam quality compared to free-space alternatives. Research demonstrates that fiber-coupled detectors provide superior signal levels and image quality in realistic applications, with coupling efficiency improvements from approximately 30% to over 70% when properly implemented. The fiber coupling process results in a circular and homogenized intensity profile with symmetric beam quality characteristics, which is particularly valuable for precision applications requiring consistent beam parameters.

Reduced Beam Divergence

Fiber coupling significantly minimizes beam divergence, allowing laser light to maintain coherence and focus over longer distances. This characteristic is crucial for precision applications where maintaining beam quality across extended transmission paths is essential. Studies show that fiber-coupled systems can achieve M² values as low as 1.15 at power levels exceeding 300 watts, representing a substantial improvement in beam quality optimization.

Improved Coupling Efficiency

Modern fiber-coupled laser systems achieve remarkable coupling efficiencies. Research indicates that properly designed fiber-coupled systems can maintain coupling efficiencies well above 70%, with some configurations achieving even higher performance levels when optimized for specific applications. This efficiency translates directly into improved system performance and reduced energy waste in precision manufacturing processes.

Flexibility and Integration Advantages

Spatial Flexibility

The primary advantage of fiber coupling lies in its exceptional spatial flexibility. Unlike free-space laser systems that require direct line-of-sight alignment, fiber-coupled sources can deliver laser energy to virtually any location accessible by the optical fiber. This capability is particularly valuable in complex manufacturing environments where laser access to the work area may be restricted or where multiple processing stations require laser input from a single source.

Easy System Integration

Fiber-coupled laser sources integrate seamlessly with existing manufacturing systems and can be easily combined with other fiber-optic components. This compatibility extends to automated manufacturing environments where consistent, repeatable laser delivery is essential. The modular nature of fiber-coupled systems allows for easy replacement of defective components without requiring system realignment, significantly reducing maintenance downtime.

Remote Processing Capabilities

The ability to transmit laser energy over extended distances through optical fibers enables remote processing applications that would be impossible with free-space systems. This capability is particularly valuable in hazardous environments, cleanroom applications, or situations where the laser source must be isolated from the processing area for safety or contamination control reasons.

Performance Advantages in Precision Manufacturing

Manufacturing Efficiency Gains

Industry data demonstrates significant efficiency improvements with fiber-coupled laser systems. Automotive manufacturers like BMW have reported production efficiency improvements of 25% when implementing fiber laser cutting machines. Similarly, companies transitioning from traditional CO₂ lasers to fiber-coupled systems have achieved cutting speed increases of up to 40% while realizing substantial energy savings.

Precision Cutting and Processing

Fiber-coupled laser sources excel in precision cutting applications, delivering exceptional edge quality and minimal heat-affected zones. The superior beam quality inherent in fiber-coupled systems enables cutting of complex geometries with tight tolerances, making them ideal for applications in aerospace, medical device manufacturing, and electronics production.

Material Versatility

Modern fiber-coupled laser systems demonstrate exceptional versatility in material processing, effectively handling metals, plastics, ceramics, and composite materials with consistent quality. This versatility is particularly valuable in manufacturing environments that process diverse material types or require rapid changeovers between different materials.

Market Growth and Industry Adoption

Robust Market Expansion

The fiber-coupled laser market is experiencing unprecedented growth, with market valuations reaching USD 1.2 billion in 2024 and projected growth to USD 2.5 billion by 2033, representing a compound annual growth rate (CAGR) of 8.9%. This growth trajectory reflects increasing industry recognition of the advantages offered by fiber-coupled systems.

Industry-Specific Applications

Multiple industries are driving adoption of fiber-coupled laser sources:

Automotive Sector: Applications include precision cutting of body components, battery module production for electric vehicles, and high-speed welding operations. Tesla has utilized fiber laser technology to optimize battery module production, enhancing both performance and manufacturing scalability.

Aerospace Industry: Fiber-coupled lasers enable cutting of high-strength alloys including titanium and Inconel, critical materials in aircraft manufacturing. The minimal heat-affected zones produced by these systems ensure compliance with stringent aerospace quality standards.

Medical Device Manufacturing: The precision and cleanliness of fiber-coupled laser systems make them ideal for manufacturing surgical instruments and implants from biocompatible materials. The non-contact nature of laser processing reduces contamination risk, a critical factor in medical applications.

Electronics Industry: Micro-cutting capabilities enable production of delicate electronic components with the precision required for modern miniaturized devices.

Technical Specifications and Performance Metrics

Power and Efficiency Statistics

Modern fiber-coupled laser systems achieve remarkable performance metrics:

- Coupling Efficiency: Superior systems achieve over 70% coupling efficiency, with optimized configurations reaching even higher levels

- Beam Quality: M² values as low as 1.15 at power levels exceeding 300W demonstrate exceptional beam quality

- Power Scaling: Systems are available across power ranges from low-power applications (under 100W) to high-power industrial applications exceeding 2000W

Manufacturing Speed Improvements

Statistical analysis of fiber-coupled laser implementation shows:

- Cutting Speed: Up to 40% improvement in cutting speeds compared to traditional laser systems

- Production Efficiency: Overall manufacturing efficiency gains of 25% or higher in automotive applications

- Material Utilization: Significant reduction in material waste due to improved cutting precision and reduced kerf width

Comparison with Free-Space Laser Systems

Operational Advantages

| Parameter | Fiber-Coupled Systems | Free-Space Systems |

| Beam Delivery Flexibility | Excellent – can reach any location accessible by fiber | Limited – requires direct line-of-sight |

| Beam Quality | Superior – circular, homogenized profile | Variable – dependent on optical alignment |

| Maintenance Requirements | Low – easy component replacement | High – requires precise optical alignment |

| System Integration | Excellent – compatible with fiber components | Limited – requires custom optical systems |

| Environmental Sensitivity | Low – fiber protects beam path | High – sensitive to vibration and misalignment |

| Installation Complexity | Simple – flexible fiber routing | Complex – rigid optical path requirements |

Performance Metrics

Research comparing free-space and fiber-coupled systems demonstrates clear advantages for fiber-coupled configurations. Studies show that fiber-coupled detectors achieve superior signal levels and image quality in realistic applications, with significant improvements in coupling efficiency when atmospheric or environmental conditions affect free-space transmission.

Cost-Effectiveness and Total Ownership Benefits

Initial Investment Considerations

While fiber-coupled laser systems typically require higher initial investment due to the cost of high-quality optical fibers and precision coupling mechanisms, this investment is offset by several factors:

- Reduced System Complexity: Simplified beam delivery reduces the need for complex free-space optical systems

- Lower Maintenance Costs: Easy component replacement and reduced alignment requirements

- Improved Reliability: Higher system uptime due to reduced sensitivity to environmental factors

Long-Term Economic Benefits

The economic advantages of fiber-coupled systems become apparent over their operational lifetime:

- Energy Efficiency: Higher coupling efficiency translates to lower operational energy costs

- Reduced Downtime: Easy maintenance and component replacement minimize production interruptions

- Scalability: Ability to serve multiple processing stations from a single laser source improves capital utilization

Applications in Emerging Technologies

Industry 4.0 Integration

Fiber-coupled laser systems integrate seamlessly with Industry 4.0 manufacturing environments, supporting real-time monitoring and precision control capabilities. The digital compatibility of these systems enables advanced automation and process optimization that would be difficult to achieve with traditional free-space systems.

Additive Manufacturing

The growing additive manufacturing sector, particularly metal 3D printing, increasingly relies on high-power fiber-coupled laser systems for precision material processing. The excellent beam quality and power stability of fiber-coupled sources make them ideal for the demanding requirements of additive manufacturing processes.

Micro-Manufacturing

The trend toward miniaturization in electronics and medical devices drives demand for precision micro-manufacturing capabilities. Fiber-coupled laser sources provide the beam quality and positioning accuracy required for micro-machining applications that would be challenging with free-space alternatives.

Quality Assurance and Process Control

Consistent Process Parameters

Fiber-coupled laser systems provide exceptional consistency in process parameters due to their inherent stability and reduced sensitivity to environmental factors. This consistency is crucial for quality assurance in precision manufacturing applications where repeatability is essential.

Real-Time Monitoring Capabilities

Modern fiber-coupled laser systems support advanced monitoring and control capabilities, enabling real-time adjustment of process parameters to maintain optimal performance. This capability is particularly valuable in high-volume manufacturing environments where consistent quality is critical.

Future Developments and Trends

Technology Advancement Trajectory

The fiber-coupled laser market continues to evolve with ongoing developments in laser technology, fiber optics, and system integration. Key trends include:

- Higher Power Levels: Development of systems capable of handling increasingly higher power levels while maintaining beam quality

- Improved Efficiency: Continued optimization of coupling efficiency and overall system efficiency

- Advanced Materials: Development of specialized fiber materials for specific wavelengths and applications

- Smart Integration: Enhanced integration with artificial intelligence and machine learning for process optimization

Market Expansion Opportunities

Emerging markets and applications continue to drive demand for fiber-coupled laser systems. The global fiber laser market is projected to reach USD 17.549 billion by 2033, growing at a CAGR of 11.1%, indicating strong continued growth in this technology sector

Frequently Asked Questions

Q: What are the primary advantages of fiber-coupled laser sources over free-space laser systems?

A: Fiber-coupled laser sources offer several key advantages including superior beam quality with circular, homogenized intensity profiles, exceptional flexibility in beam delivery to any location accessible by fiber, easier system integration and maintenance, reduced sensitivity to environmental factors, and the ability to transmit laser energy over extended distances without degradation.

Q: How does coupling efficiency compare between fiber-coupled and free-space systems?

A: Research demonstrates that fiber-coupled systems achieve superior coupling efficiency, with properly optimized systems reaching over 70% efficiency compared to approximately 30% for free-space alternatives under similar conditions. This improvement directly translates to better energy utilization and system performance.

Q: What industries benefit most from fiber-coupled laser technology?

A: Key industries include automotive manufacturing (with efficiency improvements up to 25%), aerospace (for processing high-strength alloys), medical device manufacturing (for biocompatible material processing), electronics (for micro-machining applications), and telecommunications (for high-precision component manufacturing).

Q: Are fiber-coupled laser systems more expensive than traditional alternatives?

A: While initial investment costs are typically higher due to precision coupling mechanisms and high-quality optical fibers, the total cost of ownership is often lower due to reduced maintenance requirements, higher efficiency, improved reliability, and simplified system integration.

Q: What power levels are available in fiber-coupled laser systems?

A: Modern fiber-coupled laser systems are available across a wide power range from low-power applications under 100W to high-power industrial systems exceeding 2000W, with excellent beam quality maintained even at power levels over 300W (achieving M² values as low as 1.15).

Q: How do fiber-coupled systems integrate with automated manufacturing environments?

A: Fiber-coupled laser systems integrate seamlessly with Industry 4.0 manufacturing environments, supporting real-time monitoring, precision control, and automated process optimization. Their compatibility with fiber-optic components and digital control systems makes them ideal for modern automated production lines.

Q: What maintenance advantages do fiber-coupled systems offer?

A: Fiber-coupled systems offer significant maintenance advantages including easy replacement of defective components without system realignment, reduced sensitivity to environmental factors like vibration and contamination, and simplified troubleshooting due to modular design architecture.

Conclusion

Fiber-coupled laser sources represent a fundamental advancement in precision manufacturing technology, offering compelling advantages over traditional free-space laser systems. The combination of superior beam quality, exceptional flexibility, improved coupling efficiency, and seamless system integration makes these systems indispensable for modern precision applications.

The robust market growth, with projections reaching USD 2.5 billion by 2033, reflects increasing industry recognition of these advantages. Statistical evidence from leading manufacturers demonstrates significant performance improvements, including production efficiency gains of 25% and cutting speed improvements of up to 40%.

As manufacturing continues to evolve toward greater precision, automation, and efficiency, fiber-coupled laser sources will play an increasingly critical role in enabling next-generation manufacturing capabilities. The technology’s compatibility with Industry 4.0 initiatives, combined with ongoing developments in laser technology and fiber optics, positions fiber-coupled systems as the preferred solution for precision applications across diverse industrial sectors.

For manufacturers seeking to enhance their precision manufacturing capabilities while improving operational efficiency and reducing total cost of ownership, fiber-coupled laser sources offer a proven pathway to achieving these objectives. The technology’s maturity, combined with continued innovation and market expansion, ensures that fiber-coupled laser systems will remain at the forefront of precision manufacturing technology for years to come.

CN

CN