In today’s industrial landscape, identifying leaks quickly and accurately is critical to maintaining operational efficiency and minimizing costly downtime. Whether you’re managing HVAC systems, pipelines, or automotive equipment, leaks can lead to significant losses if not addressed promptly. This is where UV fluorescent dyes become indispensable. These specialized compounds glow brightly under ultraviolet (UV) light, making even the smallest leaks visible in complex systems.

With various types of UV fluorescent dyes available—such as water-based, oil-based, and universal—selecting the right one for your specific industrial application can be challenging. This comprehensive guide will help you navigate the process of choosing the best UV fluorescent dye for leak detection in HVAC, pipeline, and automotive systems. We’ll explore dye types, key selection factors, real-world applications, and more, ensuring you have the knowledge to make an informed decision.

What Are UV Fluorescent Dyes?

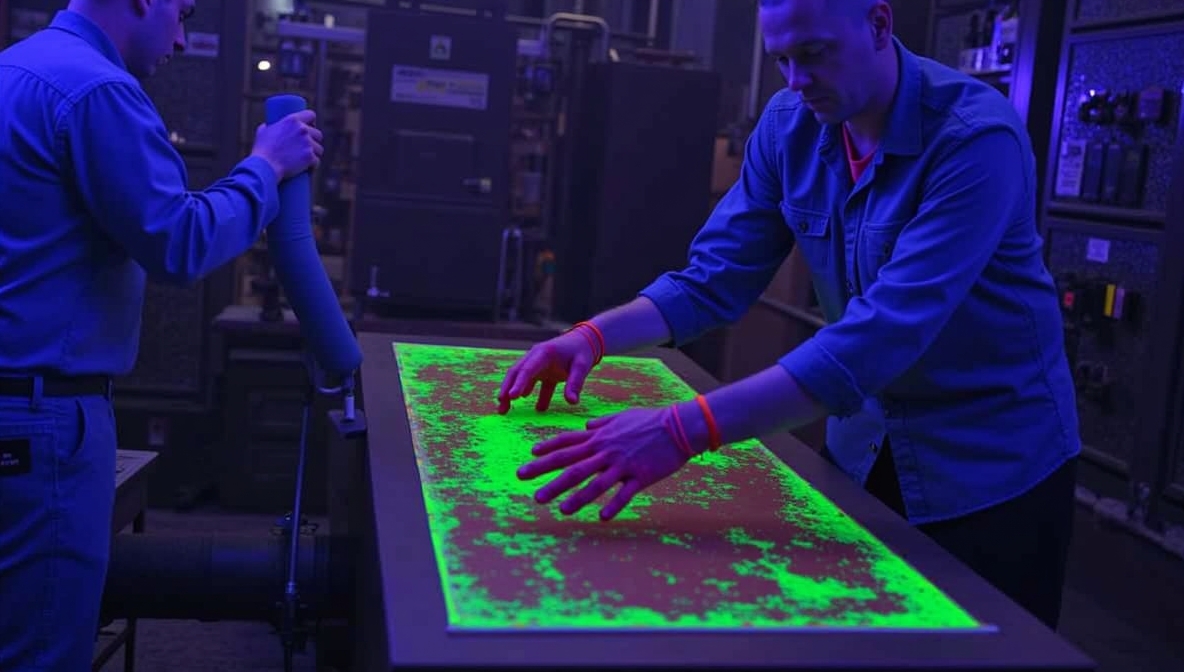

UV fluorescent dyes are chemical compounds that absorb UV light and re-emit it as visible light, creating a glowing effect that highlights leaks. When added to a system’s fluid (e.g., refrigerant, oil, or water), the dye travels with the fluid and escapes at leak points. Shining a UV light on the area reveals the glowing dye, pinpointing the exact location of the leak.

This method is highly effective for detecting leaks that are invisible to the naked eye or difficult to locate with traditional techniques like soap bubble tests or electronic sensors. According to industry studies, UV fluorescent dyes can detect leaks as small as 0.01 ounces per year in refrigerant systems, offering unmatched precision.

Types of UV Fluorescent Dyes

UV fluorescent dyes come in different formulations to suit various industrial fluids and systems. Here are the primary types:

- Water-Based Dyes: Soluble in water or water-glycol mixtures, these dyes are ideal for systems like coolant circuits or water pipelines. They’re often environmentally friendly and non-toxic.

- Oil-Based Dyes: Designed for petroleum-based fluids such as hydraulic oil, engine oil, or lubricants, these dyes are commonly used in automotive engines and oil pipelines.

- Universal Dyes: These versatile dyes work across multiple fluid types but may not perform as well as specialized dyes tailored to specific systems.

Choosing the right dye depends on the fluid in your system. For optimal results, match the dye type to the fluid’s properties to ensure compatibility and visibility.

Choosing the Right UV Fluorescent Dye for Your System

Different industrial systems have unique leak detection challenges. Below, we break down how to select the best UV fluorescent dye for HVAC, pipelines, and automotive applications.

- HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems rely on refrigerants to regulate temperature, and leaks in refrigerant lines can reduce efficiency and increase energy costs. The right dye ensures quick detection without damaging the system.

- Recommended Dye: Oil-based dyes are typically used, as most refrigerants are paired with oil-based lubricants (e.g., polyol ester or mineral oil). For water-cooled HVAC systems, water-based dyes may be appropriate.

- Considerations:

- Compatibility with refrigerants (e.g., R-410A, R-134a) and lubricants is essential. The GlobeNewswire white paper (2015) emphasizes selecting dyes that won’t degrade system components.

- High fluorescence is key for spotting small leaks in intricate refrigerant lines.

- Use dyes that comply with environmental regulations, as refrigerant leaks can release harmful substances.

Sunlonge’s SL3200 UV Fluorescent Dye is an excellent choice for HVAC systems, offering high compatibility with a range of refrigerants and lubricants, plus exceptional fluorescence under UV light (Sunlonge, 2023).

- Pipelines

Pipelines transport diverse fluids—water, oil, or chemicals—over vast distances, making leak detection a complex task. The dye must suit the fluid type and disperse effectively to reach leak sites.

- Recommended Dye:

- Water-based dyes for water pipelines.

- Oil-based dyes for oil or petroleum pipelines.

- Specialized dyes for chemical pipelines (consult manufacturer guidelines).

- Considerations:

- Dispersibility: The dye must mix evenly with the fluid to ensure visibility.

- Concentration: Larger systems may require higher dye concentrations for long-distance detection.

- Environmental Impact: Opt for eco-friendly dyes, especially in sensitive areas.

For oil pipelines, Sunlonge’s SL3200 provides reliable performance, blending seamlessly with petroleum-based fluids to highlight leaks efficiently.

- Automotive Systems

Automotive leaks can occur in engines, transmissions, power steering, or cooling systems, each requiring a dye matched to its fluid.

- Recommended Dye:

- Oil-based dyes for engine oil, transmission fluid, or hydraulic systems.

- Water-based dyes for coolant systems.

- Considerations:

- Fluid Compatibility: Ensure the dye won’t react with the system’s materials or fluids.

- Durability: Automotive systems operate under high pressure and temperature, so the dye must remain stable.

- Precision: Bright fluorescence helps detect leaks in tight engine compartments.

Sunlonge’s SL3100 UV Fluorescent Dye is a versatile option for automotive applications, compatible with both oil- and water-based fluids, making it a go-to solution for mechanics.

Key Factors to Consider When Selecting a Dye

Beyond system type, several factors influence your choice of UV fluorescent dye:

- Compatibility: The dye must integrate with the system’s fluid and materials without causing clogs or corrosion.

- Concentration and Dosage: Too little dye may not glow sufficiently, while excess dye can be wasteful. Follow manufacturer guidelines—e.g., Sunlonge recommends 1 ounce per 4 gallons of fluid for optimal results.

- Environmental and Safety: Choose non-toxic, eco-friendly dyes that meet regulatory standards, especially in HVAC and pipeline applications.

- Cost-Effectiveness: High-quality dyes may cost more upfront but save money by reducing downtime and repair expenses.

- Fluorescence Strength: Brighter dyes improve visibility, especially in low-light or hard-to-reach areas.

Real-World Impact and Statistics

UV fluorescent dyes have proven their value across industries. Here are some compelling figures:

- HVAC Efficiency: A study by ASHRAE found that UV dye-based leak detection reduces refrigerant leak detection time by up to 50%, minimizing energy loss.

- Automotive Savings: The Automotive Service Association reports that UV dyes cut diagnostic time by 30-50%, speeding up repairs.

- Pipeline Protection: Early leak detection with UV dyes can reduce fluid loss by up to 70%, preventing environmental damage and costly cleanups.

These statistics highlight why UV fluorescent dyes are a game-changer for industrial maintenance.

Q&A: Your UV Fluorescent Dye Questions Answered

Q: How do I determine the right dye for my system?

A: Match the dye to your system’s fluid—water-based for water or coolant, oil-based for petroleum fluids. Check compatibility with manufacturer specs.

Q: Can one dye work for all leak types?

A: Universal dyes exist, but specialized dyes (water- or oil-based) offer better performance for specific fluids.

Q: How much dye should I use?

A: Dosage varies by system size and dye concentration. For Sunlonge’s SL3200, use 1 ounce per 4 gallons of fluid, but always consult product guidelines.

Q: Are UV fluorescent dyes safe to use?

A: Yes, when handled properly. Wear gloves and safety glasses, and choose non-toxic dyes to minimize risks.

Table: UV Fluorescent Dye Comparison

| Dye Type | Best Applications | Key Features | Sunlonge Product |

| Water-Based | Coolant, water pipelines | Eco-friendly, water-soluble | SL3100 |

| Oil-Based | Engines, oil pipelines, HVAC | High fluorescence, oil-soluble | SL3200 |

| Universal | Mixed fluid systems | Versatile, moderate performance | SL3100 |

Conclusion

Choosing the right UV fluorescent dye for industrial leak detection is a critical decision that impacts system performance, cost savings, and environmental safety. By understanding your system’s needs—whether it’s HVAC, pipelines, or automotive—and considering factors like compatibility and fluorescence strength, you can select a dye that delivers fast, accurate results.

At Sunlonge, we offer top-tier solutions like the SL3200 and SL3100 UV Fluorescent Dyes, designed to meet the demands of diverse industrial applications. Visit http://www.sunlonge.com to explore our products and elevate your leak detection process today.

CN

CN