Our Chinese space industry has come a long way from the DFH-1, the first artificial satellite. Now the recent extraordinary successes have shifted the immense focus of the world towards these space ventures. However, delivering a successful mission requires intricate attention to structural and other details of launch vehicles, satellites, and other payloads. One of the essential details for space and their payload is quality control of its components utilizing NDT technology.

Utilizing NDT to test spacecraft components and payloads is essential to ensure they perform with full efficiency for the long term without unexpected any maintenance requirements.

Space industries have focused on different ways to improve component quality and cost-effective in every space launch. However, with commercial space tourism on the rise, the stakes to increase spacecraft safety is higher than ever before.

Whenever we think of a spacecraft, we can imagine the low gravity, extreme temperature variations, and immense pressure the launch, vehicle can withstand. Like aircraft, there is also a necessity to keep the craft light yet strong enough to carry the payload. All these pre-and post-launch activities need to be completed without a single flaw in the systems. Although each component is designed at its highest quality standards, flaws can always be a possibility. A singular flaw can mean a catastrophic failure, massive investment loss, or loss of human lives in worst-case scenarios.

Material quality, probable flaws, and their impact on the spacecraft’s performance and payloads can be examined utilizing NDT methods such as MPT and PT methods. Additionally, the advanced probes, instruments, and software help industries fulfill the high NDT standards that the components are adhered to and provide the corrective maintenance opportunity.

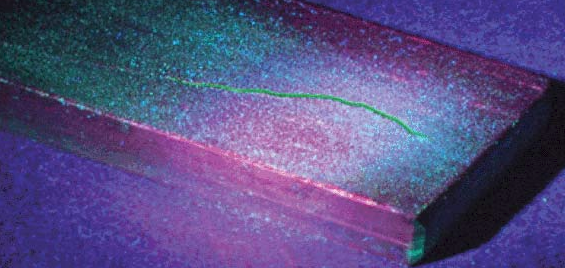

MPT and PT testing of flaws such as cracks and other surface flaws for components like spacecraft frame, turbine or engine and the heat-affected areas of the weld. The MPT and PT can test in complex and difficult to reach sections to detect minor surface and subsurface flaws, thus increasing the probability of flaw detection.

Construction and maintenance of the space shuttle and their various payloads are subjected to stringent inspection requirements. This is due to the immense risk it carries. The inspection should be carried out at greater speed with maximum accuracy and precision for the time and quality bound space missions. With the NDT of MPT and PT, the space industry can easily detect minor flaws at an early stage, saving the project from major catastrophes, with quality components, space industries can venture into successful space missions.

CN

CN