Introduction: Why Lighting Determines What Your Inspectors Can (and Can’t) See

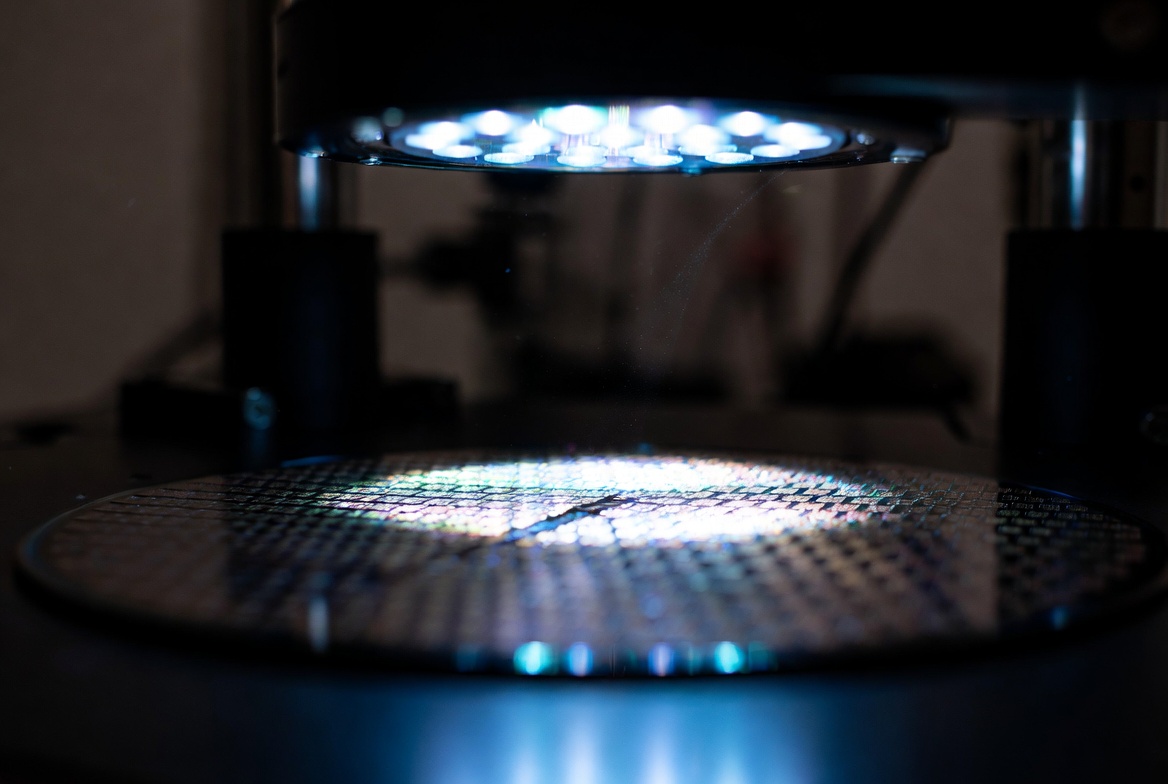

In semiconductor and electronics manufacturing, the difference between a good wafer and a scrap wafer can be smaller than a micron. Yet many fabs still rely on standard cleanroom lighting when asking operators to find dust particles, scratches, and coating defects on wafers, LCD panels, and precision components.

Standard cleanroom lights are designed for compliance, safety, and general visibility—not for ultra‑fine defect detection. By contrast, a wafer inspection lamp uses highly controlled, high‑intensity, wavelength‑optimized illumination specifically engineered to make microscopic defects “pop” to the human eye.

This article explains, in practical engineering terms, why a dedicated wafer inspection lamp like Sunlonge’s SL8900 series delivers far superior defect visibility compared with normal cleanroom lighting. It compares:

- Contrast and wavelength

- Reflection and glare control

- Defect detection accuracy

- Inspection speed and efficiency

It also highlights how Sunlonge’s technology, specifications, and application focus give it a competitive edge over many other lamps in the market.

What Is a Wafer Inspection Lamp?

A wafer inspection lamp is a high‑intensity, narrow‑spectrum LED lighting system designed to reveal extremely small surface defects that are nearly invisible under normal room or cleanroom lighting.

Typical characteristics:

- Specialized wavelength: Usually yellow, green, or yellow‑green (often around 510–590 nm), tuned to maximize human visual sensitivity and defect contrast.

- High illuminance: Light output can reach hundreds of thousands of lux at short working distances, far beyond standard overhead lighting.

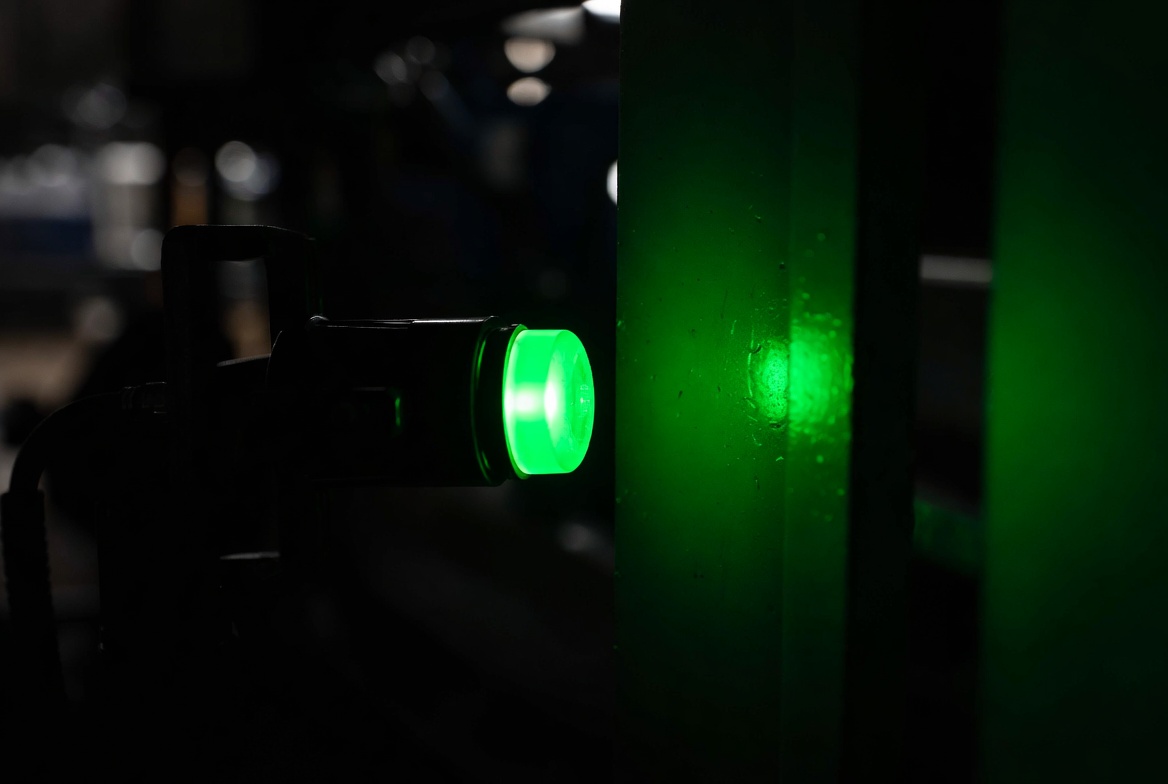

- Collimated/controlled beam: Optics and lenses shape the beam to strike the surface at angles that highlight particles, scratches, and topography.

- Flicker‑free, stable output: For consistent visual inspection and operator comfort.

- Long LED lifespan: 30,000+ hours is common in modern LED inspection platforms.

These lamps are used in:

- Silicon and compound semiconductor wafer inspection

- LCD/FPD glass and micro‑engraving molds

- Sapphire substrates and precision optical surfaces

Sunlonge SL8900: A Concrete Example

Sunlonge’s SL8900 wafer inspection lamp is a desktop, high‑illuminance LED inspection lamp specifically engineered for wafer dust particle and surface defect inspection.

Key characteristics of the SL8900 series include:

- Wavelength options:

- 6000 K white light (model SL8900‑W)

- 510–590 nm green‑yellow light (model SL8900‑GY), with other wavelengths (365 nm, 455 nm, 525 nm, 595 nm, 625 nm) available.

- Illuminance:

- Up to 400,000 lux at 30 cm working distance.

- Around 280,000–290,000 lux at 40 cm.

- Detection capability:

- Can detect dust particles in the 1 µm size range, around 10× more powerful than traditional inspection lamps.

- Optics & stability:

- 1 × 30 W imported LED with customized optical lens.

- Illuminance stability > 90%.

- Longevity & efficiency:

- LED lifespan of about 30,000 hours.

- Mechanical cooling for stable, high‑intensity output.

- Infinite dimming (0–100%) for fast adjustment to different surfaces and operator preferences.

This spec profile is significantly beyond generic task lights or cleanroom ceiling fixtures, and even above many competing surface inspection lamps which often operate around tens of thousands of lux rather than hundreds of thousands.

What Is Standard Cleanroom Lighting Designed For?

Cleanroom lighting’s primary job is to support regulatory cleanliness and safe, comfortable working conditions, not ultra‑high‑contrast defect detection.

Typical priorities for cleanroom luminaires include:

- ISO 14644 compliance: Lighting enclosures must not shed particles, and must integrate with ceilings that meet ISO Class 3–6 environments common in semiconductor manufacturing.

- Sealed, easy‑to‑clean construction: Gaskets, smooth surfaces, and high IP ratings to prevent dust ingress and facilitate wipe‑down.

- Uniform, shadow‑free illumination: To ensure that operators can work safely and read instruments, labels, and screens easily.

- High CRI (Color Rendering Index): For correct color perception in pharmaceutical, biotech, and electronics operations.

- Low heat and EMI: To avoid disturbing airflow, temperature control, or sensitive processes.

Standard cleanroom lights are usually overhead, broad‑spectrum white LEDs with wide beam angles focused on area coverage and comfort. They are not calibrated for:

- Targeted wavelengths that increase defect contrast

- Extremely high local illuminance on a specific small area

- Low‑angle collimated beams optimized for scattering from particles and scratches

This is why so many wafer manufacturers add dedicated wafer inspection lamps to their lines: cleanroom lighting ensures compliance; inspection lighting ensures yield.

Contrast & Wavelength: Why Yellow‑Green Beats White for Defect Visibility

How Human Vision Works in Inspections

The human eye is most sensitive in the green region of the spectrum, roughly around 555 nm. Industrial studies show that green LED task lighting yields substantially higher contrast for subtle surface imperfections compared to white or ambient light. When green or yellow‑green light is used on reflective or translucent surfaces, small protrusions, particles, or scratches scatter light differently, making them far more visible to the inspector.

Industrial vendors of wafer inspection systems confirm this:

- Yellow‑green lamps with 570–580 nm output are widely used because they provide high‑contrast visual wafer inspection without UV and without mercury.

- Defects such as dust, scratches, fingerprints, and oil stains that are almost invisible under normal room or cleanroom light suddenly become clearly visible when illuminated with narrow‑band yellow/green light.

Why Standard Cleanroom Lighting Falls Short

Standard cleanroom lighting typically uses:

- Wide‑spectrum white LEDs tuned for color accuracy, not defect contrast.

- Uniform, overhead illumination that tends to wash out the fine surface scatter signals inspectors need to see.

Under such lighting, subtle wafers defects:

- Blend into the background

- Are easily missed unless the operator moves around and experiments with viewing angles

- Require more time and more operator skill to detect reliably

Sunlonge’s Advantage in Wavelength Engineering

Sunlonge’s SL8900 wafer inspection lamp addresses this at the hardware level:

- The SL8900‑GY model uses a 510–590 nm green‑yellow light source—exactly in the sensitivity sweet spot of the human visual system, similar to high‑end yellow/green wafer inspection lamps from European industrial vendors.

- Other wavelengths (365 nm UV, 455 nm blue, 525 nm green, 595 nm amber, 625 nm red, and 6000 K white) can be tailored to specific processes and substrates, making Sunlonge’s system highly configurable.

Result: much higher local contrast for common wafer and surface defects compared with standard cleanroom lighting, and flexibility to tune the lamp to different materials and process steps.

Reflection & Glare Control: Collimated Beams vs. Ceiling Panels

The Problem with Overhead, Diffuse Lighting

Cleanroom ceiling fixtures are optimized for diffuse, uniform illumination, which is ideal for general work but problematic for fine defect inspection on reflective materials like wafers or glass.

Issues include:

- Specular reflections: White overhead light reflects almost directly back toward the ceiling or the observer, masking small local scattering from particles.

- Low grazing angle: The light approaches the surface at relatively high angles (near normal), reducing the ability to highlight tiny height differences.

- Glare & eye fatigue: Bright white light from many directions can contribute to operator fatigue during extended visual inspection.

How Wafer Inspection Lamps Control Light

Dedicated wafer and surface inspection lamps, including those from multiple specialist vendors, use:

- Low‑angle, collimated beams: Illuminating surfaces at glancing angles enhances the visibility of surface irregularities because small bumps and pits throw sharp highlight and shadow patterns.

- Adjustable optics and dimming: Operators can tune the intensity and angle for each substrate, improving both contrast and comfort.

- Localized, high‑intensity zones: Concentrating light in a small inspection area rather than flooding the whole room reduces stray reflections and focuses attention.

X‑Loupe, for example, notes that sticky dust particles in cleanrooms are often difficult to distinguish under ordinary lighting, but become clearly visible with specific wavelength plus a low‑angle collimated light source. This is exactly the design philosophy behind wafer inspection lamps.

Sunlonge Implementation

Sunlonge’s SL8900 series builds reflection control into its optical design:

- A customized optical lens system shapes and concentrates the beam onto a defined area (e.g., 90–200 mm diameter at typical working distances).

- Infinite dimming (0–100%) allows operators to quickly tune brightness to match surface reflectivity and avoid overexposure or glare.

- Mechanical design and mechanical cooling support stable beam characteristics for long periods of continuous operation.

Combined with wavelength tuning, this means the SL8900 can be set up for high‑contrast, low‑glare inspections that are impossible to achieve with uniform overhead cleanroom lights alone.

Defect Detection Accuracy: What You Can See vs. What You Miss

Evidence from Wafer Inspection Systems

Multiple industrial vendors document that defects which are invisible under standard ambient or room light become clearly visible under specialized wafer inspection lamps:

- Under standard lighting, particles, scratches, dust, fingerprints, and oil stains on wafers are difficult or impossible to see.

- When illuminated with yellow‑green wafer inspection lamps, the same defects stand out sharply, enabling reliable visual inspection before wafers move to cost‑intensive downstream processes.

Other surface inspection lamps for discs and LCD glass report the ability to clearly recognize minute particles and scratches smaller than 10 µm, using tailored LED spectra and optics.

Sunlonge’s Published Detection Capabilities

Sunlonge’s own technical material emphasizes:

- The SL8900 series can detect dust particles in the 1 µm size range, making it around 10× more powerful than traditional inspection lamps.

- Sunlonge’s surface inspection platforms using high‑intensity light (up to 350,000 lux at 30 cm in the SL8100 series) are designed to detect flaws significantly below what is visible under general lighting conditions.

This level of sensitivity is orders of magnitude beyond what is achievable with standard cleanroom ceiling fixtures, which are simply not engineered or specified for micron‑scale visual inspection tasks.

Types of Defects Better Seen with Wafer Inspection Lamps

Using wafer inspection lamps like Sunlonge’s SL8900, operators can more reliably spot:

- Particles and dust at and below 1 µm on wafers and masks

- Scratches, polishing swirls, and micro‑cracks

- Photoresist residues and surface contamination (especially when combined with UV or blue wavelengths)

- Coating uniformity variations and “orange peel” textures on epitaxial layers or thin films

Bright Light Inspection in wafer fabs is widely recognized as a critical complement to automated inspection systems, precisely because a properly set up high‑intensity lamp plus trained human eye can pick up a wide range of macro‑defects quickly and cheaply.

Inspection Efficiency & Yield: Throughput Gains Over Standard Lighting

Manual Inspection Under Ceiling Lights Is Slow and Inconsistent

Relying only on standard cleanroom lighting for visual wafer inspection has several drawbacks:

- Operators must constantly adjust their viewing angle and position to “catch” defects in reflection.

- Many borderline defects are missed entirely, creating rework, scrap, or downstream yield losses.

- Fatigue sets in quickly under high, uniform white light, reducing consistency over long shifts.

Even when automated metrology and inspection systems are in place, manual bright light inspection remains a key line of defense in most wafer fabs. Inefficient lighting directly translates into slower inspections and higher cost.

How Wafer Inspection Lamps Improve Efficiency

Specialized wafer inspection lighting boosts throughput via:

- Faster decision‑making: High contrast plus low‑angle illumination makes defects immediately obvious, reducing the time per wafer.

- Reduced false negatives: Better visibility means fewer missed defects and more accurate go/no‑go judgments.

- Operator comfort: Narrow‑band yellow/green light that is “sensitive but does not harm human vision” supports long inspection sessions with less eye strain compared to harsh broad‑spectrum light.

- Lower total cost of quality: Catching defects earlier in the process avoids sending contaminated or scratched wafers into expensive lithography, deposition, or packaging steps.

Sunlonge’s long‑life LED design (about 30,000 hours), high stability, and flexible optical configurations are expressly built to support high‑volume, continuous inspection with minimal downtime.

Why Sunlonge’s Wafer Inspection Lamps Outperform Many Alternatives

Many companies now offer wafer inspection lamps, but Sunlonge’s SL8900 series has several important strengths:

- Extremely High Illuminance and Stability

- Up to 400,000 lux at 30 cm—significantly higher than many general surface inspection lamps that operate around 50,000 lux.

- Illuminance stability > 90%, supported by customized optical and filter systems and mechanical cooling.

High, stable light output directly improves defect visibility and measurement repeatability.

- Optimized Yellow‑Green Wavelength Range

- The SL8900‑GY uses 510–590 nm green‑yellow light, precisely matching the range that industry experts and competitors highlight as ideal for wafer inspection.

- This dual‑color composition improves visibility for both micro‑scratches and dust particles, especially on LCD screens, micro‑engraved molds, and semiconductor wafers.

- Fine‑Grained Dimming and Optical Control

- Infinite dimming from 0–100% allows inspectors to optimize brightness and avoid glare on highly reflective surfaces.

- Controlled irradiated area (approximately 90–200 mm at typical working distances) helps focus inspection on the critical zone without flooding the entire work area.

- Long Lifespan and Low Maintenance

- Around 30,000 hours LED life, comparable to or better than other industrial surface inspection lamps and much longer than legacy mercury‑vapor systems.

- Mechanical cooling and rugged anodized construction (in related product families) support continuous 24‑hour operation with high reliability.

- Broad Application Coverage

Sunlonge’s wafer inspection lamps are used across:

- LCD screen surface inspection

- Micro‑engraving molds

- Semiconductor wafers

- Sapphire substrates and similar high‑precision surfaces

Having one platform that can adapt to multiple product lines—simply by changing wavelength or configuration—reduces equipment investment and simplifies training.

- In‑House R&D and Customization

Sunlonge has its own R&D team and manufacturing capability in China, with a long history in UV NDT lamps, leak detection, forensic inspection, and surface testing. This background supports:

- Custom wavelength combinations

- Different beam patterns or intensities

- DC models with lithium battery packs for portable use (e.g., SL8900BL variant)

This ability to tailor lamps to specific fabs, substrates, or inspection tasks is a key differentiator versus “one‑size‑fits‑all” lighting products.

Key Comparison Table: Wafer Inspection Lamp vs. Standard Cleanroom Lighting

| Feature / Metric | Wafer Inspection Lamp (e.g., Sunlonge SL8900) | Standard Cleanroom Lighting |

| Primary purpose | Maximize defect visibility on wafers, LCDs, precision parts | Provide safe, comfortable, compliant general illumination in cleanrooms |

| Typical wavelength | Narrow‑band yellow/green (e.g., 510–590 nm) or specific UV/visible LEDs tuned for contrast | Broad‑spectrum white LEDs focused on high CRI and uniform color |

| Illuminance at target | Very high; up to ~400,000 lux at 30 cm in Sunlonge SL8900 | Moderate task lighting levels, optimized for comfort and overall visibility, not specified for micron‑scale inspection |

| Beam control | Collimated or tightly controlled beam, often used at low angles to highlight defects | Wide, diffuse beam from ceiling panels; designed to minimize shadows and glare across the room |

| Defect types best revealed | Micro‑scratches, 1 µm dust particles, veils, contamination, edge defects on wafers and glass | Large‑scale issues (obvious contamination, major cracks) only; many micro‑defects remain invisible |

| Operator experience | High local contrast reduces eye strain and speeds up inspection decisions; wavelength and intensity optimized for eye sensitivity | Comfortable general lighting, but poor contrast for very fine surface irregularities; requires more effort to spot issues |

| Impact on yield | Helps catch defects early, reducing scrap and rework; complements automated inspection tools | Limited direct impact on defect discovery; mainly supports safe, compliant working environment |

| Typical use location | Workstations dedicated to visual wafer/surface inspection | Entire cleanroom or large zones (production lines, assembly areas) |

Practical Q&A About Wafer Inspection Lamps and Sunlonge

Q1: Why can’t standard cleanroom lighting deliver the same defect visibility as a wafer inspection lamp?

Standard cleanroom lights are designed to meet ISO 14644 cleanliness, safety, and visual comfort requirements, not micron‑scale surface inspection needs. They use broad‑spectrum white light, wide beam angles, and uniform distribution to avoid shadows and glare in the general workspace. By contrast, a wafer inspection lamp focuses a narrow wavelength band and very high intensity onto a specific area at carefully chosen angles, which dramatically increases the contrast of tiny particles and scratches. The difference is comparable to using a lab‑grade microscope versus reading glasses—both involve optics, but they serve very different purposes.

Q2: What specific benefits does a Sunlonge wafer inspection lamp offer for semiconductor fabs?

For semiconductor fabs, Sunlonge’s SL8900 series offers:

- Detection down to about 1 µm dust particles, around 10× better than many traditional lamps.

- Up to 400,000 lux at 30 cm, which makes even very small surface irregularities visible.

- 510–590 nm green‑yellow light optimized for visual sensitivity and defect contrast, with options for UV, blue, and other wavelengths.

- Infinite dimming and high stability, giving inspectors fine control over light levels without flicker.

- Long service life (~30,000 hours) and robust mechanical design suitable for 24/7, high‑volume production environments.

These strengths allow fabs to catch more defects earlier and support existing AOI (automatic optical inspection) rather than replacing it.

Q3: Is yellow‑green wafer inspection light safe and comfortable for operators?

Yes. One reason yellow‑green light is popular for wafer inspection is that it aligns with the peak sensitivity of human vision, meaning the eye perceives brightness efficiently without needing excessive power. Industrial case studies highlight that green/yellow inspection light:

- Provides high contrast for dust and scratches

- Is flicker‑free and mild, helping to avoid eye and body stress

- Is commonly used for long‑term visual inspection tasks in cleanrooms and precision manufacturing

Sunlonge’s lamps are designed as cold light sources with mechanical cooling, avoiding the heat and UV/mercury hazards associated with older mercury‑vapor lamps.

Q4: Do I still need automated inspection tools if I invest in wafer inspection lamps?

In modern semiconductor manufacturing, manual bright light inspection complements, not replaces, automated tools.

- Automated systems excel at systematic scanning and quantitative measurement, but they are expensive and configuration‑heavy.

- Wafer inspection lamps enable fast, flexible, human‑driven inspection for:

- Incoming wafer quality checks

- Quick line checks after process changes

- Verification of suspected problem lots

- Cross‑checking suspicious signals from automated tools

Most fabs achieve the best quality and cost balance by combining automated optical inspection with high‑quality wafer inspection lamps and trained operators.

Q5: How does a Sunlonge wafer inspection lamp integrate into an existing cleanroom?

Integration is straightforward:

- The SL8900 is a desktop, AC‑powered lamp designed for continuous 24‑hour operation at 100–240 V input, with its own mechanical cooling.

- It can be installed at dedicated inspection stations adjacent to process tools or QA benches.

- Because it is a local light source, it does not interfere with overall cleanroom lighting or airflow design, and it does not require modifications to cleanroom ceilings or HVAC.

- Dimming and beam control allow operators to adapt lighting to specific wafers, masks, or glass panels without changing room lighting parameters.

This makes Sunlonge lamps an incremental upgrade to defect visibility, not a disruptive retrofit.

Q6: Which wavelength configuration should I choose for my application?

In general:

- Yellow‑green (510–590 nm): Best general‑purpose choice for wafer inspection, micro‑engraving molds, and semiconductor/coating defects—excellent for both dust particles and scratches.

- White light (6000 K): Good for uniform coating evaluation, large‑scale contamination, and applications where color rendering is important.

- Green (~525 nm): Strong for high‑contrast detection of dust on glass, metal, and plastic surfaces.

- UV (365 nm) / blue (455 nm): Useful where fluorescence or specific surface chemistries are involved, or for certain NDT and leak detection tasks.

Sunlonge’s multi‑wavelength options and customization capabilities allow you to match the lamp precisely to your product mix and inspection challenges.

Q7: How does Sunlonge compare to other wafer inspection lamp vendors?

While several vendors provide high‑quality wafer inspection lights, Sunlonge offers a compelling combination of:

- Very high illuminance levels (up to 400,000 lux), surpassing many general industrial surface inspection lights.

- Fine‑tuned yellow‑green spectrum and multiple wavelength options matched to industry best practices.

- Proven detection performance in the 1 µm range and strong track record in UV NDT and surface inspection across multiple industries.

- Cost‑effective, desktop form factors that are easy to integrate into existing lines.

For fabs seeking to upgrade from standard cleanroom lighting or older mercury‑vapor solutions, Sunlonge represents a technically robust and economically attractive path to better defect visibility.

Conclusion: For Real Defect Visibility, Go Beyond Cleanroom Lighting

Standard cleanroom lighting is essential for regulatory compliance, safety, and everyday operations. But when it comes to seeing what actually threatens your yield—micron‑level particles, scratches, residues, and coating defects—it is not enough.

A wafer inspection lamp such as Sunlonge’s SL8900 series delivers:

- Tuned wavelengths (especially yellow‑green) that maximize human visual contrast

- Extremely high, stable illuminance for revealing sub‑micron defects

- Controlled beam geometry that enhances scattering from particles and scratches

- Efficient, long‑life LED operation suitable for 24/7 QC

In direct comparison, wafer inspection lamps clearly outperform standard cleanroom lightingon contrast, reflection control, defect detection accuracy, and overall inspection efficiency. For semiconductor fabs, LCD manufacturers, and precision optics producers serious about yield, adding Sunlonge wafer inspection lamps to key inspection points is one of the most cost‑effective ways to see more, miss less, and protect your margins.

CN

CN