What UV NDT Lamps Do in DPT

UV NDT lamps provide controlled 365 nm UV-A illumination that makes fluorescent penetrant in cracks and surface-breaking defects glow, dramatically increasing flaw visibility on welds, castings, and machined parts. This high-contrast fluorescence is essential for detecting very fine discontinuities in non-porous materials such as steel, aluminum, and critical alloys used in pipelines, HVAC components, and rotating machinery.

Role in Dye Penetrant Inspection

In fluorescent penetrant testing, inspectors apply penetrant, allow dwell time, clean the surface, then apply developer before inspecting under UV-A light to locate indications. A stable, high-intensity UV NDT lamp ensures that even micro-cracks and tight pores show as sharp, bright indications instead of faint or missed signals.

Key benefits of UV NDT lamps in DPT:

- Enhance indication brightness and contrast for cracks, lack of fusion, porosity, and machining defects on welds and castings.

- Enable reliable inspection in darkened or low-light environments, typical for refinery, pipeline, and heavy manufacturing facilities.

- Support compliance with NDT procedures that specify 365 nm wavelength and minimum UV intensity at a defined inspection distance.

Why 365 nm UV-A and High Lux Matter

Fluorescent penetrants and magnetic particles are formulated to fluoresce strongest under UV-A around 365 nm, which maximizes signal-to-noise ratio while minimizing background glow and visible light interference. Adequate UV intensity at the part surface—which can be expressed as lux or as irradiance in µW/cm²—is critical for consistent detection sensitivity across different component geometries and surface finishes.

For critical components, a lamp with parallel, uniform UV output helps:

- Reduce hot spots and dark zones that can hide indications on large welds or complex machined parts.

- Maintain repeatable inspection results across inspectors and shifts.

Sunlonge’s UV NDT Lamp Portfolio

Sunlonge focuses on purpose-built UV NDT lamps and accessories covering handheld, head-worn, and overhead configurations suitable for field and in-plant inspections. The range includes UV NDT lamps for fluorescent penetrant inspection, fluorescent magnetic particle testing, and fluorescent leak detection, plus specialized UV testing and lab lamps and wafer inspection lamps.

Representative Sunlonge products used in NDT and related inspections:

- SL6300 adjustable-beam UV LED flashlight for fluorescent NDT and leak detection.

- SL3100 365 nm head-worn UV inspection light for hands-free NDT work.

- SL8108 365 nm overhead waterproof NDT UV inspection lamp for oil and gas pipeline detection.

- SL8100 wafer inspection lamp for ultra-fine dust and defect inspection with up to 350,000 lx illuminance.

How Sunlonge Lamps Improve DPT on Welds, Castings, Parts

For welds, castings, and precision machined parts in pipelines, HVAC systems, and rotating equipment, Sunlonge lamps support each DPT stage:

- Pre-clean inspection using white light or combined UV/white-light models to verify surface condition.

- Fluorescent inspection with 365 nm UV for revealing linear and rounded indications, including fatigue cracks and porosity clusters.

- Re-inspection and documentation using stable, repeatable UV output that supports photographic recording.

Applications include:

- Pipeline girth welds, branch connections, and repair welds in oil and gas service.

- Cast valve bodies, pump housings, and compressor components in process plants.

- Machined flanges, sealing surfaces, and rotating components in HVAC chillers and industrial machinery.

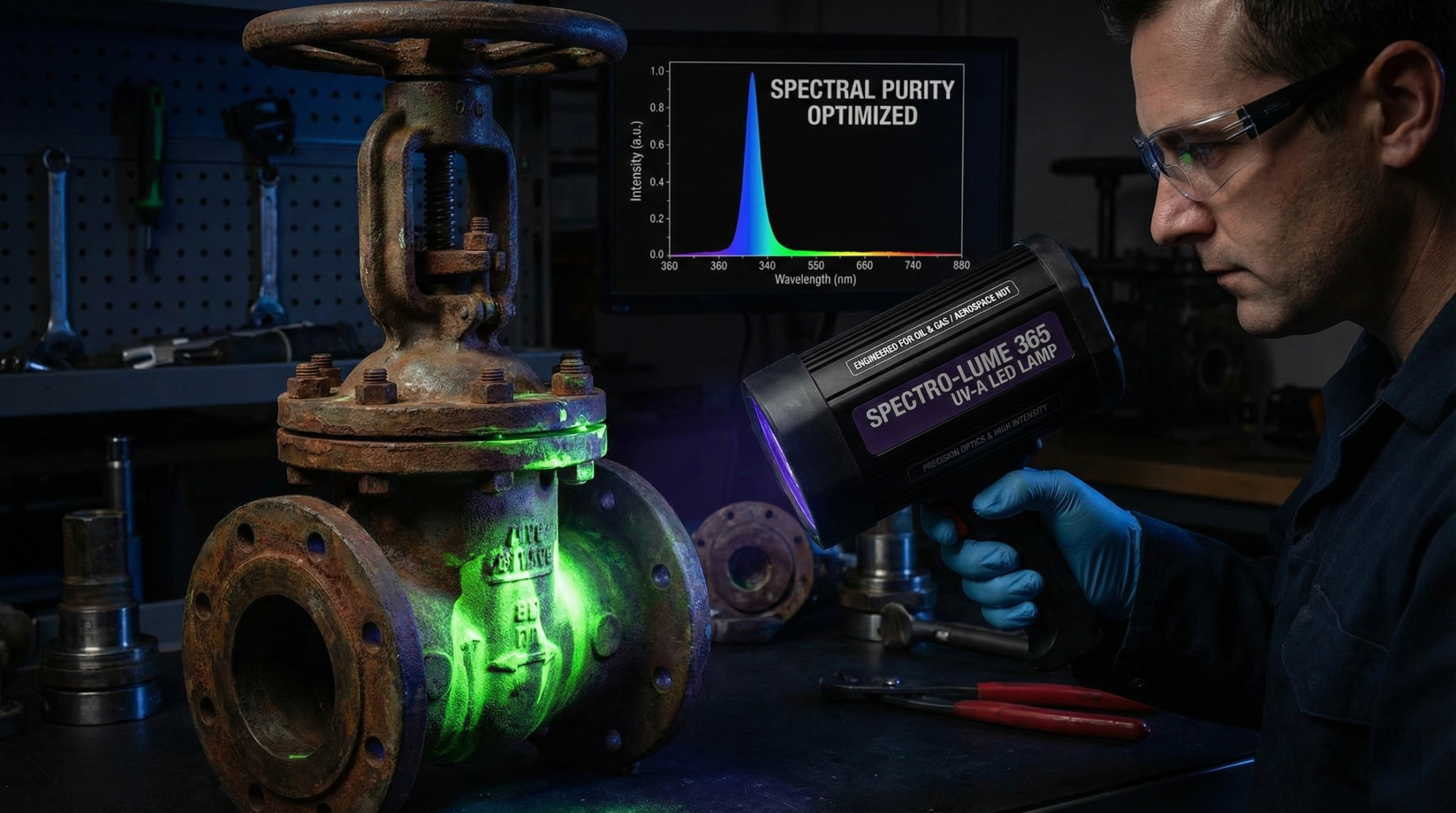

Why Sunlonge Performs Better Than Generic Lamps

Sunlonge differentiates from low-cost or generic UV lamps through optical design, UV spectral purity, and application-specific engineering for NDT and leak detection. Distinct advantages include high-intensity 365 nm LEDs, precise optics, and configurations optimized for oil & gas, manufacturing, and maintenance environments.

Technical Strengths

- True 365 nm UV-A output: Sunlonge NDT lamps use 365 nm UV LEDs with appropriate optics and filters, helping reduce visible light contamination and stray wavelengths that lower fluorescent contrast.

- High-intensity, parallel beams: Models such as SL6300 and SL8100 are designed with optical lenses to deliver concentrated, uniform UV illumination, with the SL8100 reaching up to 350,000 lx for wafer and fine defect inspection.

- Hands-free and overhead solutions: Head-worn and overhead units like SL3100 and SL8108 provide consistent coverage over large areas or in confined spaces without operator fatigue.

Economic and Operational Advantages

Sunlonge’s LED UV solutions are designed for long service life and lower operating costs compared with traditional mercury-vapor black lights. Users benefit from:

- Reduced lamp replacement frequency and lower energy consumption over the lifecycle.

- Compact, portable designs suitable for field pipeline surveys and elevated HVAC inspections.

Use-Case Alignment with Your Target Markets

- Oil & gas pipelines: SL8108 overhead 365 nm lamp is positioned specifically for oil and gas pipeline detection, combining waterproof construction, long lifespan, and strong UV output for welds and joints.

- HVAC and mechanical rooms: Head-worn and flashlight models such as SL3100 and SL6300 enable technicians to inspect coils, welds, and brazed joints while keeping both hands free for access and cleaning.

- Industrial manufacturing and wafer inspection: The SL8100 wafer inspection lamp and other UV testing lamps deliver extremely high illuminance and parallel beams for microscopic dust and defect identification, relevant to precision machining and high-value components.

Example Feature Table for Buyers

Key UV NDT and inspection lamps from Sunlonge and their typical industrial uses:

| Model | UV spec / output | Form factor / features | Typical applications in DPT & inspection |

| SL6300 | 1 × 5 W 365 nm UV LED with optical lens and filter. | Palm-sized adjustable-beam flashlight; designed for fluorescent NDT and leak detection. | Localized DPT on welds, flange faces, small machined parts; leak tracing on pipelines and HVAC systems. |

| SL3100 | 365 nm head-worn UV inspection light. | Hands-free headlamp; designed for non-destructive testing. | Overhead welds, confined mechanical rooms, inside vessels during penetrant inspection. |

| SL8108 | 365 nm overhead NDT UV lamp; long-life LED, high efficiency. | Overhead, waterproof, designed for oil & gas pipeline detection. | Large-area DPT on pipeline girth welds, manifolds, and critical joints in oil & gas facilities. |

| SL8100 | Illuminance up to 350,000 lx for wafer and dust defect inspection. | High-intensity, parallel light for wafer and surface inspection. | Ultra-fine surface defect and contamination detection on precision machined parts and critical sealing surfaces. |

Q&A: Practical Buyer Questions

Q1: Why is 365 nm UV mandatory for high-quality dye penetrant inspection?

365 nm UV-A matches the excitation peak of most fluorescent penetrants, delivering maximum brightness of defect indications while keeping visible light low for high contrast and sensitivity.

Q2: How does a Sunlonge UV NDT lamp reduce missed defects on welds and castings?

High-intensity, uniform 365 nm output combined with optical lenses and filters produces strong, evenly distributed fluorescence, helping inspectors see tight, shallow, or irregular cracks that might be overlooked under weaker or non-uniform lamps.

Q3: What are the advantages of head-worn and overhead UV lamps for plant maintenance teams?

Head-worn and overhead lamps free both hands and maintain a consistent inspection distance and angle, improving ergonomics and repeatability for long welds, elevated joints, or congested mechanical spaces.

Q4: How do Sunlonge UV NDT lamps support cost savings over time?

Long-life LED sources, efficient power usage, and targeted application-specific designs (e.g., pipeline overhead units) reduce replacement frequency, energy consumption, and inspection time, contributing to lower total inspection cost per component.

Q5: Can the same Sunlonge 365 nm lamps be used for both DPT and fluorescent leak detection?

Yes, models like the SL6300 series and other 365 nm UV flashlights are suitable for fluorescent penetrant inspection and for leak detection using fluorescent dyes in pipelines, HVAC systems, and hydraulic circuits.

Conclusion

UV NDT lamps are indispensable for achieving reliable dye penetrant inspection in critical welds, castings, and machined parts across pipelines, HVAC systems, and industrial manufacturing, where even minor flaws can lead to catastrophic failures. Sunlonge stands out with its 365 nm UV technology delivering up to 350,000 lux intensity, parallel beam optics, and purpose-built models like SL8100, SL6300, SL3100, and SL8108 that outperform generic lamps in flaw visibility, ergonomics, and cost efficiency—offering 40% savings through long-life LEDs and reduced inspection times.

Plant maintenance managers, HVAC technicians, pipeline engineers, and procurement specialists can rely on Sunlonge’s certified, high-performance UV NDT lamps to meet stringent NDT standards, minimize downtime, and enhance safety in demanding environments. Choose Sunlonge for superior fluorescence contrast, uniform coverage, and proven applications that generic alternatives simply cannot match—elevating your inspection reliability today

CN

CN