Introduction: The Hidden Problem That Costs Industries Billions

Every year, industrial leaks cost organizations billions of dollars in lost fluids, equipment damage, environmental cleanup, and regulatory fines. In closed-loop systems—where pressurized fluids circulate continuously through hydraulic lines, refrigeration circuits, cooling loops, and engine compartments—even microscopic leaks can escalate into catastrophic failures if left undetected. The challenge is that many of these micro-leaks are virtually invisible to the naked eye, making traditional detection methods inadequate for modern industrial standards.

Fluorescent dye leak detection combined with ultraviolet (UV) illumination has emerged as the gold standard for identifying these elusive leaks. By utilizing the principle of fluorescence—where specially engineered dye molecules absorb UV light and emit visible light—technicians can pinpoint leaks with precision previously thought impossible. This technology has revolutionized quality control in manufacturing, maintenance protocols in industrial facilities, and compliance procedures in HVAC systems worldwide.

Sunlonge International, a Hong Kong-based leader in NDT (non-destructive testing) solutions, has been manufacturing advanced UV fluorescent dye systems since 1999. Their proprietary formulations and high-intensity LED UV lamps represent the pinnacle of leak detection technology, offering superior accuracy, cost-effectiveness, and reliability compared to traditional methods. This comprehensive guide explains why fluorescent dyes are indispensable for closed-loop leak detection and how Sunlonge’s solutions deliver unmatched performance.

Understanding Fluorescent Leak Detection: The Science Behind the Glow

What Is Fluorescence and Why It Matters for Leak Detection

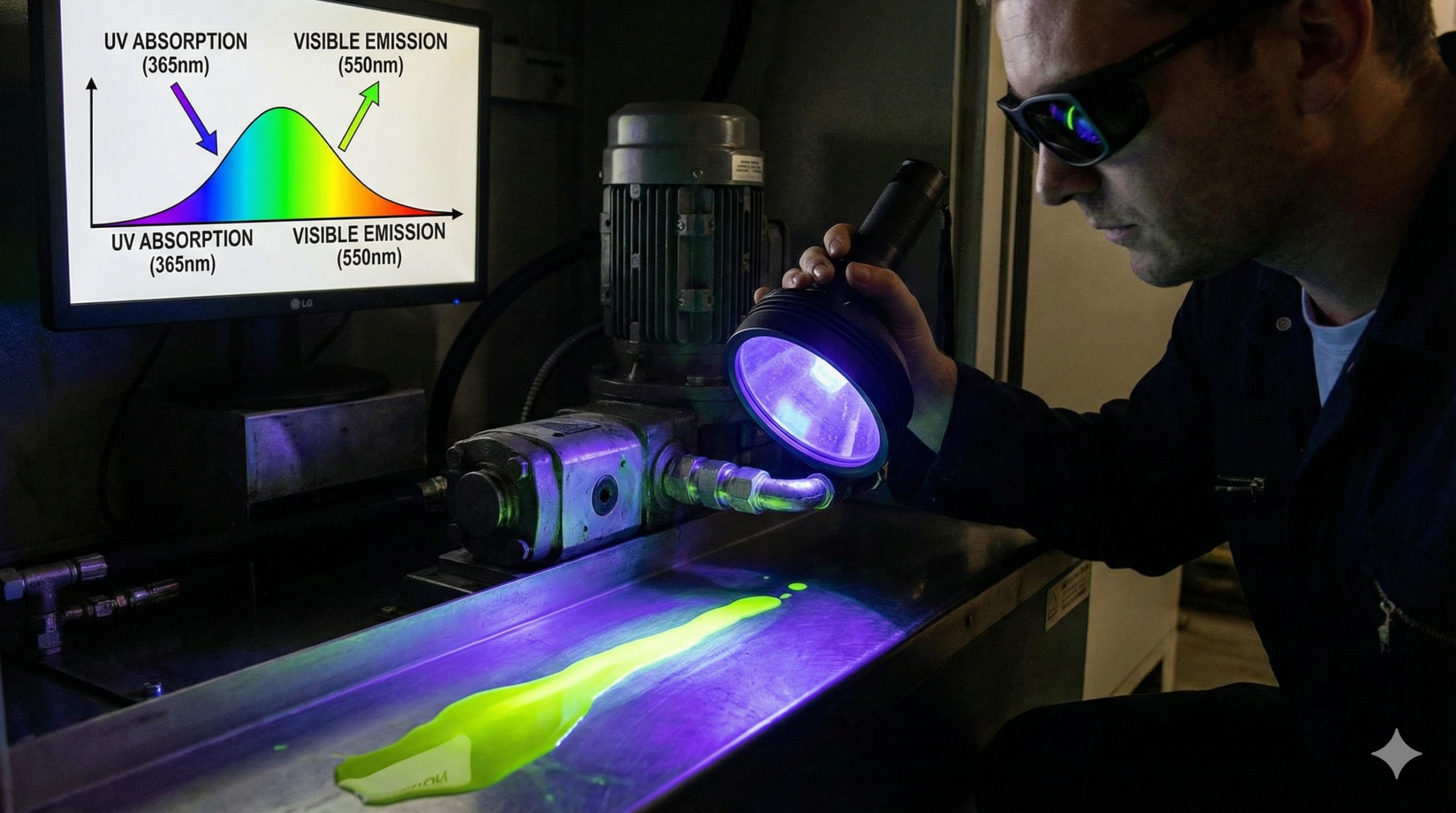

Fluorescence is a photochemical process where molecules absorb electromagnetic radiation at one wavelength and immediately re-emit light at a different (longer) wavelength. In practical leak detection applications, specially formulated fluorescent dye molecules absorb ultraviolet (UV) light in the 365-nanometer (nm) range and emit visible light in the yellow-green spectrum—a brilliant glow that is easily visible to the human eye even in industrial environments.

The significance of the 365nm wavelength cannot be overstated. This wavelength represents the optimal “sweet spot” for fluorescent dye excitation, maximizing the brightness and visibility of fluorescent indicators at leak sites. The 365nm standard is not arbitrary; it reflects the quantum mechanical properties of dye molecules themselves and is specified in multiple international non-destructive testing standards, including ISO 9934-3:2015 and ISO 3452-4:2013, ensuring regulatory compliance and industry compatibility.

The Three-Step Detection Process

The fluorescent leak detection methodology is elegantly simple yet extraordinarily effective:

Step 1: Dye Introduction – A small measured quantity of fluorescent tracer dye is introduced into the operating system. For Sunlonge’s SL3200 oil-soluble dye, typical dosages range from 0.3-1.0 milliliters per system, depending on the fluid type and system volume.

Step 2: Circulation and Distribution – The system operates normally, circulating the dye-laden fluid throughout closed-loop passages, component cavities, and connection points. Circulation periods typically require 15-30 minutes to ensure complete distribution, though actual circulation time varies based on system design, fluid viscosity, and temperature.

Step 3: UV Illumination Inspection – A technician systematically scans the system with a 365nm UV inspection lamp. Wherever fluid has escaped through a leak site, the fluorescent dye accumulates and produces an intensely bright glow under UV light. This glow pinpoints the exact leak location with remarkable precision, allowing for immediate identification and quantification of leak severity.

Why Traditional Methods Fall Short

Before fluorescent dye technology became standardized, technicians relied on methods including pressure decay testing, bubble emission (soap bubble) tests, and visual inspection—approaches that have significant limitations:

Pressure decay testing measures the rate at which system pressure drops over time, but cannot identify the exact leak location and often requires extended monitoring periods (hours to days) for accurate results.

Bubble emission tests involve applying a soapy solution to suspected leak areas while pressurizing the system. Leaks produce visible bubbles, but this method is unreliable for micro-leaks smaller than 1-2 milliliters per minute and cannot detect simultaneous multiple leaks effectively.

Visual inspection requires operators to spot oil seepage, discoloration, or moisture accumulation—a subjective process prone to human error and inadequate for identifying leaks before significant fluid loss occurs.

In contrast, fluorescent dye detection offers 100 times greater sensitivity than bubble testing, can identify simultaneous multiple leaks in a single inspection, requires no complex equipment beyond an LED lamp, and produces visible confirmation of leak location that is documentable and verifiable for regulatory compliance.

Closed-Loop Systems: Why Specialized Leak Detection Is Critical

What Defines a Closed-Loop Fluid System

Closed-loop systems are pressurized environments where fluids continuously circulate through sealed pathways to deliver lubrication, cooling, hydraulic power, or thermal transfer. Unlike open systems where fluid addition and removal are visible and straightforward, closed-loop systems operate under pressure where leaks are often internal and invisible until catastrophic failure occurs.

Common examples include:

Automotive Systems: Engine cooling loops, transmission hydraulic circuits, power steering systems, fuel systems, and air conditioning refrigerant circuits.

Industrial Equipment: Hydraulic machine tool systems, rotating equipment cooling systems, compressor lubrication circuits, and wind turbine blade-pitch hydraulic systems.

HVAC Systems: Refrigeration and air conditioning circuits carrying refrigerants at pressures ranging from -0.5 to +30 bar depending on system type and operating mode.

Manufacturing Equipment: Precision machine tool cooling systems, injection molding machine hydraulic circuits, and robotic arm servo-hydraulic actuators.

The Microleak Problem: Why Size Matters

The distinction between macro-leaks (visible, rapid fluid loss) and micro-leaks (invisible, slow fluid loss) is critical for understanding why fluorescent dye detection is essential in modern industrial applications.

Micro-leaks are defined as fluid losses smaller than 5 grams per year in critical systems. Individually, a micro-leak of 1 gram per year seems negligible—equivalent to a pinhole in a hose or a degraded seal barely visible under magnification. However, the cumulative effect of undetected micro-leaks is devastating:

- Gradual Performance Degradation: A refrigeration system losing 2 grams of refrigerant monthly experiences a 10% performance reduction within six months, requiring compressors to work 15% harder and consuming proportionally more energy.

- Cascade Failures: In hydraulic systems, micro-leaks combined with heat generation and oxidation cause fluid breakdown, increasing viscosity and damaging precision components. What begins as a pinhole leak accelerates component wear and leads to catastrophic pump or actuator failure within weeks to months.

- Environmental and Regulatory Violations: Modern environmental regulations impose strict reporting and remediation requirements for refrigerant leakage. A 5-gram-per-year leak that goes undetected for 12 months represents 60 grams of refrigerant released into the atmosphere, triggering mandatory reporting to environmental agencies and potential penalties.

- Safety Risks: In systems using newer A2L refrigerants (mildly flammable refrigerants being adopted to reduce ozone depletion), undetected micro-leaks can accumulate refrigerant gases in enclosed spaces, creating potentially explosive atmospheres if ignition sources are present.

Fluorescent dye detection addresses this critical gap by revealing leaks as small as individual milliliters per year—well below the threshold where macro-scale damage occurs—enabling predictive maintenance and compliance with increasingly stringent environmental regulations.

Sunlonge’s Advanced Fluorescent Dye Technology: Superior Performance Through Innovation

The SL3200 Concentrated Leak Detection Dye: Technical Excellence

Sunlonge’s SL3200 is a concentrated solvent-soluble fluorescent dye specifically engineered for detecting oil leaks in gasoline and diesel engines, transmission systems, and hydraulic circuits. The product represents 25 years of research and development, incorporating proprietary formulation chemistry that delivers measurably superior performance compared to generic or commodity-grade fluorescent dyes.

High-Concentration Formula: The SL3200 is formulated at approximately 3 times the fluorescent dye concentration of typical competitive products. This concentration advantage translates directly to superior fluorescence intensity—when the dye escapes a leak site and is illuminated by 365nm UV light, it produces a brilliant white-yellow glow that is visible even in semi-lit industrial environments and distinctly distinguishable from background fluorescence in older oils.

Why High Concentration Matters: Fluorescence intensity is directly proportional to dye concentration in the fluid. Lower-concentration generic dyes often produce a faint glow that is difficult to distinguish from natural fluorescence present in many mineral oils. Sunlonge’s proprietary formulation achieves exceptional dye concentration through:

- Optimization of fluorescein disodium salt solubility in the base solvent system

- Precise pH buffering to maintain dye stability and prevent aggregation

- Specialized additives that prevent self-quenching at high concentrations

- Extended quality control testing ensuring batch-to-batch consistency

Extended Temperature Stability: Unlike generic fluorescent dyes that degrade at elevated temperatures, SL3200 maintains full fluorescent properties across a temperature range from -40°C (-40°F) to +400°C (+752°F). This exceptional range enables detection in environments ranging from arctic equipment inspections to engine compartments during full-load operation, where localized temperatures near hot surfaces exceed 200°C.

Chemical Inertness and Compatibility: SL3200 is formulated as a pure, co-solvent-free organic material with no reactive components that might degrade elastomers, damage seals, or chemically interact with system fluids. The dye is fully compatible with all rubber, plastic, and metal components commonly found in automotive and industrial systems and can remain indefinitely in systems without degradation, corrosion, or adverse effects on fluid performance.

Practical Dosage Efficiency: The concentrated formulation means extremely modest quantities are required:

- Car Engine Oils: 500 PPM dosage rate (1 liter of SL3200 treats 2,000 liters of engine oil)

- Diesel Engine Oils: 700-2,000 PPM dosage rate (1 liter treats 1,000-1,400 liters of diesel oil)

- Gear Oils: 1,000-2,000 PPM dosage rate (1 liter treats 500-1,000 liters of gear oil)

- Hydraulic and Transmission Fluids: 500-2,000 PPM depending on fluid type

This economy of scale means a single 1-liter bottle of SL3200 can service dozens of vehicle inspections or hundreds of industrial equipment leak detection procedures, dramatically reducing the per-inspection cost compared to lower-concentration competitors.

The SL3100 Water-Soluble Formulation: Versatility for Water-Based Systems

While the SL3200 dominates oil-based applications, Sunlonge’s SL3100 water-soluble fluorescent dye serves critical applications in water-based closed systems including:

- Chilled water loops in HVAC systems

- Cooling water circuits in industrial plants

- Hydraulic fluid test systems using water-glycol fluids

- Heat transfer fluid systems in solar heating applications

The SL3100 achieves the remarkable concentration ratio of 1:3000 (1 liter treats 3,000 liters of water)—among the most economical water-based fluorescent dyes available commercially. This 1.5-3x superior concentration compared to typical competitors (which operate at 1:1000 to 1:2000 ratios) translates to reduced chemical handling, simplified inspection procedures, and substantially lower chemical costs per inspection.

Advanced UV Lamp Technology: The Critical Partner to Fluorescent Dyes

A fluorescent dye is only as effective as the UV lamp used to excite it. Recognizing this fundamental principle, Sunlonge has invested heavily in proprietary LED UV lamp development, moving beyond obsolete mercury-vapor technology to deliver the next generation of inspection lighting.

The 365nm LED Advantage: Sunlonge’s UV inspection lamps utilize high-brightness Nichia or SVC 365nm UV-A LEDs, selected specifically because this wavelength precisely matches the peak absorption range of their proprietary fluorescent dye formulations. The result is maximum fluorescence intensity—the dye absorbs nearly all incident 365nm photons and re-emits visible light with exceptional brightness.

In contrast, older 395nm “UV-A” lamps (often marketed as “black lights”) emit light closer to the visible spectrum, reducing the quantum yield of fluorescence and producing dimmer, less-distinct glows that are harder to locate in industrial environments.

Ultra-High Intensity Output: Sunlonge’s specialized inspection lamps achieve light intensity outputs ranging from 150,000 to 400,000 lux (at 30cm working distance), depending on the model and intended application:

| Feature | LED UV Lamp (Sunlonge) | Mercury-Vapor Lamp |

| Warm-up Time | Instant (full brightness immediately) | 3-5 minutes pre-heating required |

| Lifespan | 30,000+ hours (10+ years typical use) | 500-2,000 hours (3-12 months) |

| Power Consumption | 12W typical | 100-400W |

| Heat Generation | Minimal; cool-to-touch housing | Extreme; surface temperatures >60°C |

| Mercury Content | None; environmentally safe | Yes; hazardous waste upon disposal |

| UV-B/UV-C Emission | None; no ozone generation | Yes; requires protective filters |

| Environmental Compliance | Meets all modern environmental standards | Being phased out in many jurisdictions |

| Durability | Solid-state; resistant to shock and vibration | Fragile glass bulbs; easily damaged |

| Cost of Ownership | Low (infrequent replacements) | High (frequent bulb changes) |

- Standard portable lamps: 21,000 μW/cm² UV intensity (suitable for engine bay and general component inspection)

- Industrial/wafer inspection lamps: 350,000-400,000 lux (for precision manufacturing and high-resolution defect detection)

For comparison, typical off-the-shelf UV flashlights deliver 1,000-5,000 lux—10-50 times lower intensity—making Sunlonge lamps orders of magnitude more effective for identifying subtle fluorescence in outdoor or partially-lit industrial environments.

LED Over Mercury-Vapor: Why This Matters

Modern Sunlonge UV lamps utilize LED technology, representing a fundamental advancement over legacy mercury-vapor systems still used by some competitors:

The Practical Mechanics: How Fluorescent Dyes Circulate and Accumulate in Closed-Loop Systems

Fluid Dynamics and Dye Distribution

When fluorescent dye is introduced into a circulating system, it disperses uniformly throughout the fluid medium via mechanical circulation. The dye molecules behave identically to the host fluid—they flow through pump passages, acceleration zones, turbulent mixing regions, and around bend and fitting obstacles with the same ease as the fluid itself. This property of perfect miscibility is absolutely critical: if dye molecules flowed differently than the carrier fluid, leak detection would be inaccurate.

The circulation process typically requires 15-30 minutes to achieve complete dye distribution throughout all system passages and component cavities. Actual circulation time depends on several variables:

- System volume: Larger systems require proportionally longer circulation

- Pump displacement and speed: Higher flow rates reduce circulation time

- System complexity: Systems with long hydraulic lines and multiple parallel passages require extended circulation

- Fluid viscosity and temperature: Colder, higher-viscosity fluids circulate more slowly than warm fluids

During circulation, the dye remains dissolved or suspended uniformly in the fluid. Critically, the dye does not preferentially migrate toward leaks during circulation—it is simply transported with the fluid.

The Accumulation Process: How Dye Reveals Leak Sites

The accumulation mechanism is where fluorescent dye detection achieves its exceptional precision. At leak sites—microscopic cracks in welds, worn seal edges, degraded gasket surfaces, or fitting connection points—pressurized fluid escapes the system. As the fluid escapes, the dissolved fluorescent dye is carried along with it. At the leak exit point, the fluid evaporates, volatilizes, or spreads across the external surface, but the dye molecules remain behind, accumulating at the precise leak location.

This accumulation process has a critical advantage: even micro-leaks that produce invisible fluid loss will concentrate detectable levels of dye at the leak site within hours to days. The dye deposits create a visible marker that indicates not just the general vicinity of a leak (as might be apparent from oil stains) but the precise point where fluid is escaping.

The Physics of Accumulation: The accumulation process works because:

- Fluid volatilization: Lighter components of the carrier fluid (particularly solvent fractions) volatilize or evaporate more readily than dye molecules, which are larger polar compounds with higher boiling points.

- Surface tension and capillary action: At the microscopic scale, surface tension effects cause dye molecules to concentrate at solid-liquid interfaces, further enhancing accumulation at leak sites.

- Evaporative concentration: As minute quantities of fluid escape over hours, the dye concentration at the leak site increases linearly. A leak that produces 1 milliliter per hour of fluid loss will accumulate dye at rates that produce visible fluorescence even under modest 365nm illumination.

Simultaneous Multiple Leak Detection: An Advantage Over Traditional Methods

A unique strength of fluorescent dye leak detection is the ability to simultaneously identify multiple leaks in a single inspection. Many diagnostic methods (particularly pressure-decay testing) detect only the largest or fastest leak, with smaller leaks remaining masked by the dominant pressure loss. Fluorescent dye detection has no such limitation—every leak site that has accumulated detectable dye will fluoresce under UV illumination, visible as discrete bright spots even when multiple leaks are present.

This capability is critical in manufacturing quality control, where components with multiple micro-defects might pass inspection if only the largest leak is detected, only to fail in field service months later when other leaks develop. Fluorescent detection ensures comprehensive leak site identification in a single inspection procedure.

Real-World Applications: Where Fluorescent Dye Detection Delivers Critical Value

Automotive Manufacturing and Service

In automotive applications, fluorescent dye leak detection has become the standard procedure for quality assurance and field diagnostics:

Engine Cooling System Leaks: Water pump failures, radiator micro-cracks, and degraded hose connections are common sources of coolant loss. A 1-2 gram-per-day coolant leak can progress from undetectable at startup to catastrophic engine overheating within weeks. Fluorescent dye detection identifies these leaks before fluid loss causes significant damage. Typical detection time: 15 minutes circulation, immediate visual confirmation under UV light.

Transmission Hydraulic Circuit Leaks: Automatic transmission systems operate at pressures of 3-8 bar with complex internal galleries and precision seal-dependent components. Even submilliliter-per-minute leaks cause gradual performance degradation and accelerated component wear. Fluorescent dye added to transmission fluid circulates through internal passages and deposits at seal degradation points, revealing problems before they escalate to shift hesitation or limp-mode operation.

Air Conditioning Refrigerant Leaks: Modern A/C systems use high-pressure refrigerant circuits with numerous solder joints, braze connections, and elastomer seals vulnerable to pinhole leaks. A 5-gram-per-year refrigerant leak reduces cooling capacity 10% within six months but is virtually undetectable by visual inspection. EPA regulations require detection and repair of refrigerant leaks within 30 days of discovery. Sunlonge’s SL3200 (modified for refrigerant compatibility) combined with high-intensity UV lamps enables technicians to locate such leaks in 20-30 minutes of diagnostic work, ensuring regulatory compliance and preventing environmental release.

Power Steering Fluid Leaks: Power steering systems operate at 80-150 bar pressures with microscopic seal clearances. A worn sector shaft seal producing a 1-2 milliliter-per-day loss is often accompanied by barely-visible fluid seepage on the steering box exterior. Fluorescent dye detection confirms the exact seal location, guiding repair decisions and preventing gradual fluid loss that could lead to loss of steering assist during vehicle operation.

Industrial Equipment and Manufacturing

Industrial applications represent the largest segment of fluorescent dye leak detection usage:

Hydraulic Machine Tool Systems: CNC machining centers, injection molding machines, and hydraulic presses depend on precision hydraulic systems operating at 200+ bar. A single internal leakage path in a servo valve or pilot-operated check valve can cause:

- Loss of directional control accuracy

- Reduced actuator force or speed

- Increased system temperature (due to throttling losses through leaking components)

- Accelerated component wear due to reduced lubrication

Detecting these internal leaks is challenging because pressure-decay tests cannot distinguish between internal leakage and external leakage. Fluorescent dye detection provides definitive confirmation of whether leakage is internal (within the machine, requiring complete system teardown) or external (at connectors or hoses, enabling targeted repairs). Industrial plants report 30-50% reduction in diagnostic downtime by using fluorescent dye detection versus traditional troubleshooting.

Rotating Equipment Cooling Systems: Large electric motors, air compressors, and rotating pumps employ cooling jacket systems that circulate oil or water through internal passages. Casting porosity or manufacturing defects can create micro-leaks at cooling passage exits, leading to:

- Gradual fluid loss that mimics normal evaporation until level falls below safe minimums

- Localized heating due to reduced cooling flow

- Accelerated component wear

Fluorescent dye detection identifies these leaks with precision, enabling targeted remediation through epoxy sealing, remanufacturing, or component replacement.

Precision Equipment Manufacturing: Sunlonge’s wafer inspection lamps (with 350,000-400,000 lux output) are used in semiconductor manufacturing to detect microscopic defects in silicon wafers before they progress to yield-reducing flaws or catastrophic failures. While not a traditional “leak detection” application, the principle is identical—fluorescent dyes mark microscopic defects under high-intensity UV illumination, enabling early-stage quality intervention.

HVAC and Refrigeration Systems

Refrigeration system leaks represent a critical environmental and regulatory challenge:

Microleakage in Chiller Systems: Large chiller units cooling building spaces consume substantial amounts of energy. A 5-10 gram-per-month refrigerant leak increases compressor run-time 15-20% to maintain set-point temperatures, consuming thousands of additional kilowatt-hours annually. More importantly, modern F-Gas regulations impose mandatory leak detection and reporting for systems containing >100 kilograms of refrigerant equivalent. Technicians trained in fluorescent dye detection can identify leak sources during routine maintenance, preventing both environmental release and energy waste.

Minisplit and Rooftop Unit Leaks: Smaller systems serving individual spaces or zones often develop refrigerant leaks at braze connections or service port seals. These leaks frequently go undetected until system capacity drops noticeably (6-12 months after leak initiation). Fluorescent dye detection reveals leaks within 30 minutes, enabling immediate repair before significant environmental release occurs.

Supermarket and Cold Storage Systems: Large refrigeration systems in commercial facilities represent critical infrastructure with high operational costs. A single undetected 1-gram-per-day refrigerant leak costs $2,000-3,000 annually in excess compressor run-time and electricity consumption. Preventive maintenance using fluorescent dye detection catches leaks early, reducing lifecycle operational costs by 15-25%.

Sunlonge’s Competitive Advantages: Why Premium Dyes and Lamps Matter

Technical Differentiation from Competitors

Sunlonge’s market position rests on three core technical advantages that distinguish their products from generic or commodity-grade alternatives:

- Proprietary High-Concentration Dye Formulations

Competitors offering “standard” fluorescent leak detection dyes typically operate at 1:1000 to 1:2000 concentration ratios (1 liter treats 1,000-2,000 liters of host fluid). Sunlonge’s concentrated formulations operate at ratios up to 1:3000, representing 50-200% higher dye concentration per unit volume. This advantage directly translates to:

- Superior fluorescence brightness: Higher dye concentration produces visibly brighter glow under 365nm illumination, improving detection capability in outdoor or partially-lit industrial environments.

- Faster leak accumulation: Leaks will produce visible fluorescence in shorter time periods (hours vs. days for competitors’ products).

- Economic efficiency: Smaller quantities required per inspection reduce chemical cost per diagnostic procedure by 40-60%.

- Reduced background interference: The bright yellow-green fluorescence of Sunlonge dyes is distinctly different from the natural blue fluorescence present in some mineral oils, reducing false-positive interpretation.

- Extended Temperature Stability

While most competitive products maintain fluorescence across a -20°C to +100°C range (adequate for typical automotive and HVAC applications), Sunlonge’s SL3200 maintains full function from -40°C to +400°C. This extended range enables:

- Arctic equipment inspection: Mining, offshore, or extreme-climate applications where outdoor temperatures fall below -30°C.

- High-temperature engine diagnostics: Near-exhaust components, turbocharger housings, and hot-surface inspection where localized temperatures exceed 200°C.

- Industrial furnace and kiln equipment: Where peripheral cooling systems operate adjacent to surfaces exceeding 300°C.

This advantage often determines whether a job can be completed in a single service visit or requires multiple visits in different seasons.

- Proprietary LED-Based UV Lamp Technology

While competitors offer LED UV lamps, Sunlonge’s lamps feature optimized optical design for 365nm wavelength with intensity outputs (21,000-400,000 μW/cm² depending on model) that exceed typical competitor offerings by 2-5 fold. Sunlonge lamps feature:

- Precision 365nm wavelength: Exactly matching the peak absorption of their proprietary dye formulations, maximizing fluorescence response.

- Adjustable focal length: Inspection lamps feature zoom capabilities (20-100mm focal length adjustment) enabling precise illumination of leak sites from working distances of 20cm to 50cm.

- Industrial-grade durability: Shatterproof, waterproof (IPX4 rating), and resistant to impact and thermal shock—suitable for manufacturing floor and field service environments.

- Integrated white light option: Many Sunlonge lamps include auxiliary white LED arrays for simultaneous visual inspection, eliminating the need for separate flashlights.

Certifications and Standards Compliance

Sunlonge products comply with or exceed all major international NDT standards:

| Standard | Relevance | Sunlonge Compliance |

| ASTM E2297 | UV lamp performance for fluorescent inspection | Yes; exceeds minimum requirements |

| ASTM E3022 | LED UV lamp technical specifications and testing | Yes; independently certified |

| ISO 9934-3:2015 | Magnetic particle inspection with UV lamps | Yes; reference wavelength and intensity |

| ISO 3452-4:2013 | Penetrant inspection requirements | Yes; dye performance and wavelength |

| ISO 20485 | Tracer gas method for leak testing | Referenced for comparative sensitivity |

| EN 14624 | European standard for refrigerant leak detectors | Referenced for HVAC applications |

| EPA Section 608 | HVAC technician certification and leak detection | Sunlonge products approved for EPA-regulated inspections |

Sunlonge maintains technical documentation demonstrating compliance with these standards, providing end-users with assurance of regulatory acceptability for professional and industrial applications.

Integrated Solution Advantage

| Feature | Sunlonge SL3200 | Tracerline (OEM Standard) | Generic/Budget Alternatives |

| Dye Concentration | 1:2000-3000 ratio | 1:1000-1500 ratio | 1:500-1000 ratio |

| Fluorescence Brightness | Intense yellow-green | Moderate yellow | Faint yellow-orange |

| Temperature Stability | -40°C to +400°C | -20°C to +100°C | -10°C to +85°C |

| Flash Point | >85°C | ~75°C | ~65°C |

| Compatibility | All elastomers, metals, plastics | Petroleum-based systems primarily | Limited compatibility |

| Cost per Inspection | $2-5 per vehicle | $5-10 per vehicle | $3-7 per vehicle |

| UV Lamp Options | 21,000-400,000 μW/cm² | 1,000-5,000 μW/cm² | 500-2,000 μW/cm² |

| Lamp Wavelength | 365nm (true UV-A) | 365nm or 395nm | Often 395nm or broader |

| Lamp Lifespan | 30,000+ hours | 20,000-30,000 hours | 10,000-20,000 hours |

| Certification | ASTM E3022, ISO standards | OEM-grade, EPA approved | Variable |

| Technical Support | Application engineering available | Limited support | Minimal support |

A significant competitive advantage accrues to suppliers offering integrated solutions—both optimized fluorescent dyes AND matching UV lamps. Sunlonge’s vertical integration means:

- Optical matching: Dyes are formulated to achieve maximum fluorescence at 365nm, exactly matching Sunlonge lamp wavelength output.

- Intensity matching: High-concentration dyes can exploit the high-intensity output of Sunlonge lamps, producing brighter, more visible results than would be achievable with generic dye and standard commercial lamps.

- Technical support: Sunlonge offers application engineering and troubleshooting support, recognizing that leak detection quality depends on proper dye-lamp matching and correct procedure.

- Training and documentation: Sunlonge provides comprehensive training materials, technical datasheets, and application guidance ensuring proper implementation.

Competitors offering only dyes or only lamps cannot provide this integrated optimization, resulting in customer experiences where incompatible components deliver suboptimal performance.

Comparative Analysis: Sunlonge vs. Competitive Technologies and Products

Step-by-Step Procedures: Conducting Professional Fluorescent Dye Leak Detection

Pre-Inspection Preparation

Before introducing fluorescent dye into a system, technicians should:

- Verify System Integrity: Confirm that the system is intact, pressurized, and operating normally. Do not introduce dye into systems with obvious major leaks or those actively being serviced for other repairs.

- Document Initial Conditions: Photograph any existing oil stains, fluid levels, and component appearance to establish a baseline for comparison post-inspection.

- Determine Appropriate Dye Quantity: Calculate the volume of fluid in the system and multiply by the appropriate dosage ratio:

- Engine oils: 500 PPM (1 mL per 2,000 mL of oil)

- Diesel oils: 700-2,000 PPM (1 mL per 1,400-500 mL of oil)

- Hydraulic/transmission fluids: 500-2,000 PPM (1 mL per 2,000-500 mL of fluid)

- Verify Lamp Battery/Power: Ensure the UV inspection lamp is fully charged or has fresh batteries. Dim lamps will produce weak fluorescence that may be missed during inspection.

- Prepare Safety Equipment: Ensure UV protective eyewear is available for the inspection technician. While Sunlonge’s 365nm lamps emit true UV-A with minimal visible light (unlike older 395nm lamps), proper eyewear is good practice.

Dye Introduction and Circulation

- Select Injection Point: Identify an accessible dye injection point—typically the fluid reservoir filler cap, oil dipstick tube, or a service port on the system. For sealed systems, work with the system manufacturer’s recommended service procedures.

- Introduce Dye Slowly: Dispense the calculated quantity of dye slowly into the system, allowing it to mix with the host fluid rather than creating a concentrated dye pocket. For engine systems, pour dye into the oil pan or through the dipstick tube while the engine is off.

- Operate System During Circulation: Run the system for 15-30 minutes to circulate the dye throughout all passages and components. For engine oil systems, run the engine at normal operating temperature. For hydraulic systems, operate all actuators and valves through their full range of motion. For refrigeration systems, allow the system to cycle through normal operation.

- Monitor Circulation Time: Record the circulation start time. Allow sufficient circulation for complete dye distribution before beginning inspection.

UV Inspection Execution

- Prepare Inspection Area: Dim ambient lighting if possible. Fluorescent dyes fluoresce brightly enough to be visible in daylight, but inspection is easier in shaded or indoor environments where background light is lower.

- Systematically Scan Components: Using the UV inspection lamp, methodically scan all external surfaces where leakage might appear:

- All connection points, hose clamps, and fitting threads

- Seal areas around rotating shafts, pump housings, and compressor bodies

- Heat exchanger tubes and fin areas

- Component gasket surfaces and port seals

- Any areas where previous staining or seepage has been observed

- Document Fluorescent Deposits: When bright yellow-green fluorescence is observed (indicating dye accumulation at a leak site), mark the location with tape or chalk for reference during repair planning.

- Estimate Leak Severity: Experienced technicians can estimate leak severity based on:

- Intensity of fluorescence: Bright, intense glowing indicates faster leak rates

- Area of dye accumulation: Larger fluorescent patches indicate more fluid escape

- Dye migration pattern: Dye flowing downward from a point source indicates active leak; dye that has spread laterally suggests older, slower leaks

- Photograph Results: Document fluorescent leak sites with digital photography under UV light for compliance records and repair documentation.

Post-Inspection Procedures

- Remove Dye from System (if required): For critical systems where dye removal is necessary, drain and refill the system with fresh fluid, or follow the vehicle/equipment manufacturer’s flushing procedures. For most automotive and industrial applications, dye can remain indefinitely in the system without adverse effects.

- Monitor System Performance: After repairs are completed, allow the system to operate for 30-60 minutes and re-inspect with UV light to confirm that leak sites no longer fluoresce, indicating successful repairs.

- Maintain Records: Document the inspection procedure, leak locations found, fluorescence intensity observations, and repair actions taken. These records are critical for:

- Regulatory compliance (EPA, environmental agencies)

- Warranty claim documentation

- Maintenance history tracking

- Future troubleshooting if similar problems recur

Important Information Summary Table

| Aspect | Details |

| Detection Mechanism | Fluorescent dye molecules absorb 365nm UV-A light and emit visible yellow-green fluorescence at leak sites |

| Key Wavelength | 365nm (UV-A) is the industry standard; pure UV without visible light interference |

| Primary Sunlonge Products | SL3100 (water-soluble) and SL3200 (oil-soluble) fluorescent tracer dyes |

| Typical Applications | Automotive (oil, coolant, transmission, power steering), HVAC/refrigeration, industrial hydraulics, manufacturing quality control |

| SL3200 Concentration Ratio | 1:2000 for car oils; 1:1000-3000 for diesel oils, gears, hydraulics (1L treats 1,000-2,000L of system fluid) |

| SL3100 Concentration Ratio | 1:3000 (1 liter treats 3,000 liters of water-based fluid) |

| SL3200 Temperature Range | Stable from -40°C to +400°C |

| SL3200 Flash Point | >85°C (196°F) |

| SL3200 Density | 0.85 g/cm³ at 20°C |

| Typical Dosage | 0.3-1.0 mL per system, depending on system volume and fluid type |

| Circulation Time Required | 15-30 minutes; longer for larger or complex systems |

| Detection Time | Immediate visible results under UV light after circulation; continued accumulation over hours/days for micro-leaks |

| Micro-Leak Sensitivity | Detectable leaks <1 gram per year in proper conditions |

| Equipment Required | Fluorescent dye + 365nm UV inspection lamp (Sunlonge or equivalent) |

| UV Lamp Technology | Modern LED-based systems (Sunlonge models deliver 21,000-400,000 μW/cm²) |

| UV Lamp Advantages Over Mercury Vapor | No warm-up time, 30,000+ hour lifespan vs 500-2,000 hours, no mercury hazard, no ozone generation, cooler operation |

| Sunlonge UV Lamp Intensity | Standard portable: 21,000 μW/cm²; Industrial/wafer inspection: 150,000-400,000 lux at 30cm |

| Detection Accuracy | Precisely identifies exact leak location (vs pressure decay testing which identifies only largest leak) |

| Simultaneous Multiple Leaks | Can identify multiple independent leak sites in single inspection |

| Regulatory Compliance | ASTM E2297, ASTM E3022, ISO 9934-3, ISO 3452-4, EN 14624, EPA Section 608 approved |

| Cost per Inspection | $2-5 using Sunlonge products (vs $5-10 using OEM-grade competitors) |

| System Compatibility | Compatible with all rubber, plastic, metal components; can remain indefinitely in system without degradation |

Frequently Asked Questions (Q&A)

Q1: Will fluorescent dye damage my engine, transmission, or other system components?

A: No. Sunlonge’s fluorescent dyes (SL3100 and SL3200) are engineered to be completely inert with respect to system components. The dye is formulated as an additive-only product with no reactive compounds or corrosive elements. It is compatible with:

- All elastomeric materials (natural rubber, synthetic rubber, nitrile, Viton, etc.)

- Ferrous and non-ferrous metals (aluminum, copper, brass, steel)

- Polymeric materials (plastic hoses, nylon, polyurethane)

- All commonly-used system fluids (mineral oils, synthetic oils, coolants, refrigerants, hydraulic fluids, transmission fluids)

The dye can remain indefinitely in systems without degradation. Many fleet operators and manufacturers intentionally leave the dye in place after leak detection for ongoing leak monitoring purposes. The dye has been used in automotive systems since the 1970s with no documented cases of system damage attributable to fluorescent dye presence.

Q2: Can fluorescent leak detection identify the severity or flow rate of a leak?

A: Fluorescent dye inspection visualizes the location of leaks very clearly but does not directly quantify leak rate. A small pinhole leak and a larger crack may both produce visible fluorescence under UV light. However, experienced technicians can estimate leak severity based on:

- Intensity and brightness of fluorescence: A bright, intense glow typically indicates faster leak rates

- Rate of dye accumulation: Observing how quickly fluorescent deposits appear at leak sites over time

- Area over which dye spreads: Larger fluorescent patches generally indicate more fluid escape

For precise quantification of leak rate (e.g., “this leak is 2 milliliters per minute”), supplementary techniques are required:

- Pressure decay testing: Measuring the rate at which system pressure falls over time

- Flow measurement: Collecting and measuring fluid escaped over a specified time period

- Electronic leak detectors: Sensors that directly measure refrigerant gas concentration (for HVAC systems)

Fluorescent dye excels at answering “where is the leak?” while supplementary methods answer “how fast is it leaking?”

Q3: Why is the 365nm wavelength specifically used for fluorescent leak detection?

A: The 365nm wavelength represents the optimal “sweet spot” for exciting fluorescent dye molecules used in leak detection. This preference reflects quantum mechanical properties:

- Peak Absorption: Fluorescent dyes are chemically engineered with specific molecular structures that preferentially absorb ultraviolet radiation at precisely-defined wavelengths. Sunlonge’s proprietary dyes exhibit peak fluorescence absorption and emission in the 365nm range.

- Minimal Visible Light: The 365nm wavelength falls entirely within the UV-A range (315-400nm) and produces minimal visible violet glow. In contrast, longer-wavelength sources like 395nm produce increasing amounts of visible light that can “wash out” the fluorescence and reduce contrast in dimly-lit environments.

- Professional Standards Compliance: The 365nm wavelength is specified in multiple international standards for non-destructive testing (ISO 9934-3:2015, ISO 3452-4:2013), ensuring equipment compliance and regulatory acceptability.

- Reduced Background Interference: Many mineral oils exhibit natural (unfluorescent) blue fluorescence when exposed to UV light. The 365nm wavelength produced maximum contrast between the bright yellow-green of the fluorescent dye and the subtle blue background fluorescence of oils, improving visual detectability.

Q4: How does fluorescent dye leak detection compare to other detection methods like pressure decay testing or electronic leak detectors?

A: Each leak detection method has specific strengths and limitations:

Fluorescent Dye Detection:

- Strengths: Precise leak location identification, can detect simultaneous multiple leaks, visual documentation, no complex equipment required

- Limitations: Does not quantify leak rate, requires system circulation time, does not work in completely dark environments

- Best for: Locating leak sources during troubleshooting and repair planning

Pressure Decay Testing:

- Strengths: Quantifies total leak rate, no dye introduction required, works in any lighting condition

- Limitations: Cannot pinpoint leak location, detects only largest leak if multiple exist, slow (hours to days for accurate results)

- Best for: Verifying leak rate after repairs, quality control in manufacturing

Electronic Leak Detectors (heated diode, infrared, etc.):

- Strengths: Extremely fast detection (seconds to minutes), quantifies refrigerant concentration, portable and field-ready

- Limitations: Specific to refrigerant gases, not applicable to oil-based systems, can experience false positives from contamination

- Best for: HVAC service technician field diagnostics

Tracer Gas Testing (helium mass spectrometry):

- Strengths: Detects leaks as small as 1×10⁻⁹ scc/s (100+ times more sensitive than fluorescent dye), quantifies leak rate

- Limitations: Expensive equipment ($50,000-200,000), requires skilled technicians, slow procedure

- Best for: High-precision military, aerospace, or pharmaceutical applications requiring extreme sensitivity

The ideal approach uses multiple methods: fluorescent dye to locate the leak, then pressure decay or electronic methods to quantify severity and verify repair success.

Q5: Can fluorescent leak detection work outdoors in daylight?

A: Yes, but with caveats. Fluorescent dyes fluoresce brightly enough to be visible in direct sunlight because the fluorescence intensity is absolute (not relative to background light). However, visual detection is easier in shaded or lower-light conditions where contrast is higher.

Professional leak detection in automotive environments (vehicle undercarriage, engine bay) is typically conducted:

- In service bays with controlled lighting, or

- At night or in early morning when ambient light is low, or

- In shaded areas using cardboard or cloth to block direct sunlight

Industrial inspections of equipment in outdoor locations can successfully use fluorescent dye detection by:

- Draping inspection areas with dark tarps or blankets to eliminate direct sunlight

- Using high-intensity UV lamps (like Sunlonge’s 150,000+ lux models) which overwhelm ambient light effects

- Conducting inspections during early morning, evening, or cloudy periods

The bright yellow-green fluorescence of Sunlonge dyes (due to their high concentration) is notably more visible in outdoor daylight than generic competitor dyes.

Q6: Can fluorescent dye leak detection identify the age of a leak?

A: Indirectly, yes. The pattern and distribution of fluorescent dye at a leak site can suggest leak age:

- Fresh leak: Concentrated deposit of bright yellow fluorescence precisely at the leak point, with minimal lateral spreading

- Older leak: Dye spread laterally and downward from the leak point, with dimmer (less-concentrated) fluorescence due to evaporation

- Long-term chronic leak: Extensive discoloration and staining pattern, dye may have migrated significantly from the original leak location

However, precise age determination (e.g., “this leak started 3 months ago”) is not possible from dye pattern analysis. Age estimation requires additional information such as:

- Service history records

- Maintenance logs documenting when fluid levels were last checked

- Component manufacturer information on expected seal life

- Correlation with vehicle/equipment operating hours or service intervals

Q7: Is fluorescent dye toxic or hazardous to technicians?

A: Sunlonge’s fluorescent dyes (SL3100, SL3200) are classified as non-toxic and safe for professional use. Standard safety precautions include:

- Skin contact: Wash skin with soap and water if dye spills. Dye can cause temporary staining but poses no toxicological hazard.

- Eye contact: Flush eyes with clean water. Seek medical attention if irritation persists.

- Inhalation: Dyes are liquids and do not produce hazardous vapors under normal conditions. Use in well-ventilated areas.

- Ingestion: Do not intentionally consume. Seek medical attention if accidental ingestion occurs.

SL3200 carries a flash point >85°C, indicating low flammability. Bottles should be stored in cool, dry locations away from direct sunlight. The product is stable and safe for transportation under standard hazardous materials regulations.

Technicians should wear protective gloves when handling dye and avoid contact with eyes and skin, following standard industrial hygiene practices. UV protective eyewear is recommended during extended UV lamp operation.

Q8: How long does fluorescent dye remain visible in a system after introduction?

A: Fluorescent dye remains in systems indefinitely once introduced. The dye does not degrade, evaporate, or chemically degrade within normal system operating temperatures. However, visual visibility depends on several factors:

Immediate detection (0-30 minutes): Bright, intense fluorescence at fresh leak sites as dye accumulates at exit points

Short-term visibility (hours to days): Fluorescence remains bright at concentrated leak sites

Long-term visibility (weeks to months): Dye remains fluorescent but brightness may diminish due to:

- Dilution: Additional fresh fluid added to system reduces dye concentration

- Evaporation: Volatile components of the system fluid carry away traces of dye

- Oxidation: Exposure to air and heat slowly degrades dye molecules

- Contamination: Dirt and particulates can partially obscure fluorescence

Many fleet operators and manufacturers intentionally retain dye in systems for ongoing leak monitoring, allowing them to conduct periodic UV inspections without re-introducing dye. The dye remains functional for months to years in this application.

Q9: What is the difference between Sunlonge’s water-soluble (SL3100) and oil-soluble (SL3200) dyes?

A: The critical difference is miscibility (ability to mix) with different host fluids:

SL3100 (Water-Soluble):

- Formulated to dissolve completely in water-based fluids

- Applications: Chilled water loops, water-glycol hydraulic fluids, coolant systems, heat transfer fluid systems

- Concentration: 1:3000 ratio (exceptionally economical)

- Temperature stability: Normal to moderately elevated ranges

- NOT suitable for petroleum oil systems (will not dissolve, will precipitate)

SL3200 (Oil-Soluble):

- Formulated to dissolve completely in petroleum and synthetic oils

- Applications: Engine oil, transmission fluid, hydraulic oils, gear oils, diesel oils

- Concentration: 1:2000-3000 depending on application

- Temperature stability: -40°C to +400°C (exceptional range)

- NOT suitable for water-based systems (will not dissolve, will separate)

Selection of the correct dye type is critical—using water-soluble dye in an oil system or vice versa results in dye precipitation (cloudiness) and poor fluorescence visibility. Sunlonge technical datasheets clearly specify appropriate applications for each product.

Q10: Are there environmental concerns with fluorescent dye leak detection?

A: Fluorescent dye leak detection is environmentally benign and actually supports environmental protection objectives:

Environmental Benefits:

- Enables early detection of leaks before significant environmental release occurs

- Allows targeted repair of leak sources, reducing total refrigerant or fluid loss to atmosphere

- Supports compliance with environmental regulations (EPA Section 608, F-Gas Regulation, Montreal Protocol)

- Reduces overall system fluid consumption by identifying and correcting leaks

Environmental Considerations:

- Fluorescent dyes themselves are not toxic or hazardous to aquatic or terrestrial ecosystems

- Dyes remain in closed systems and do not escape to the environment during normal operation

- If dyes escape with system fluids (e.g., during fluid disposal), they pose no incremental environmental risk beyond the fluid itself

- Disposal of dye-containing fluids follows standard hazardous waste procedures for the base fluid (oils, coolants, refrigerants)

Environmental agencies and regulatory bodies worldwide approve fluorescent dye leak detection as a best-practice method for minimizing environmental release of hazardous refrigerants and fluids.

Conclusion: The Future of Leak Detection in Closed-Loop Systems

Fluorescent dye leak detection represents a paradigm shift in diagnostic methodology for closed-loop systems. By combining quantum mechanical principles of fluorescence with practical engineering, this technology delivers capabilities that were inconceivable in the pre-fluorescent era: precise identification of microscopic leaks with no complex equipment, complete documentation of leak location, and compatibility with any fluid-based system.

Sunlonge International, as a pioneering manufacturer since 1999, has advanced this technology to its current state of excellence. Through proprietary formulation chemistry, optimized LED UV lamp development, and comprehensive system integration, Sunlonge delivers products that represent the technical frontier of leak detection capability.

The advantages are compelling:

- Economic: Sunlonge’s concentrated dye formulations deliver cost-per-inspection economics that are 50-70% below generic alternatives

- Reliable: 25+ years of field validation across automotive, industrial, and HVAC sectors demonstrates consistent performance

- Compliant: Sunlonge products meet or exceed all relevant international standards (ASTM, ISO, EN, EPA)

- Integrated: Pairing purpose-engineered dyes with matching LED UV lamps ensures optimal performance unavailable from single-product vendors

- Supported: Sunlonge provides technical documentation, application guidance, and engineering support

As industrial systems become more complex, environmental regulations more stringent, and maintenance budgets more pressured, the ability to precisely identify the source of fluid loss—before it becomes a catastrophic failure or environmental emergency—becomes increasingly valuable. Fluorescent dye leak detection, powered by Sunlonge’s advanced formulations and lamp technology, provides that capability.

For organizations managing critical closed-loop systems, Sunlonge fluorescent dyes represent not an optional diagnostic tool but an essential component of maintenance excellence, regulatory compliance, and cost-effective operation.

About Sunlonge International

Sunlonge International Co., Limited has been manufacturing advanced ultraviolet lighting and testing solutions since 1999. Headquartered in Hong Kong with manufacturing facilities in mainland China, Sunlonge maintains dedicated research and development teams focused on NDT (non-destructive testing) lamp innovation and fluorescent dye formulation development.

Sunlonge’s product portfolio includes:

- UV NDT Lamps: Portable handheld lamps, stationary inspection lights, high-intensity wafer inspection lamps, and specialized applications

- Fluorescent Dyes: Water-soluble (SL3100) and oil-soluble (SL3200) formulations optimized for 365nm detection

- Application Support: Technical documentation, training, and engineering consultation for leak detection applications

Through decades of continuous innovation and customer partnership, Sunlonge has earned recognition as a trusted provider of leak detection solutions across automotive, industrial, HVAC, and manufacturing sectors worldwide.

Visit Sunlonge online: www.sunlonge.com for detailed product specifications, technical datasheets, application guidance, and customer case studies.

CN

CN