In industrial pipeline systems, detecting leaks quickly and accurately is critical to maintaining operational efficiency and preventing potential damage. Leaks, whether small or large, can lead to significant operational costs, environmental hazards, and safety risks. Pipelines Fluorescent Leak Detection Dyes offer an advanced, efficient solution for locating leaks, even in the most challenging environments. These dyes, when exposed to ultraviolet (UV) light, exhibit a fluorescence that makes the leaks clearly visible to technicians, enabling faster repairs and minimizing downtime.

In this article, we will explain how fluorescent leak detection dyes work in industrial pipeline systems. This will include the science behind their function, the role of UV light in detecting leaks, and why they are an essential tool for industries that rely on pipelines for transporting fluids and gases.

What Are Pipelines Fluorescent Leak Detection Dyes?

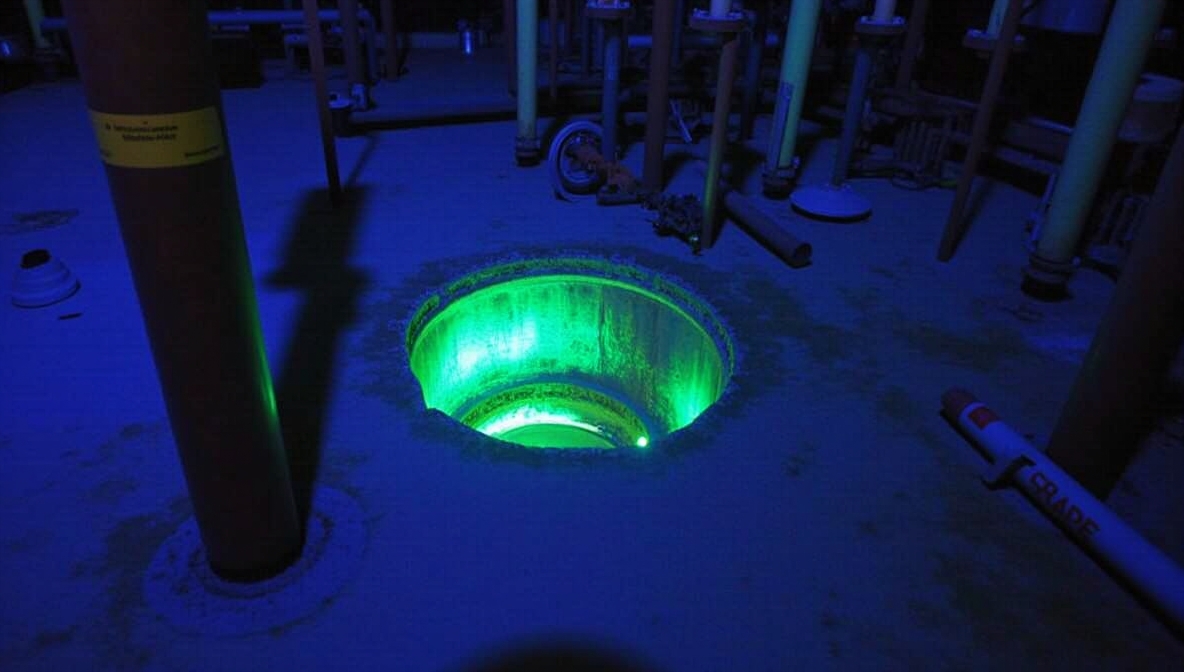

Fluorescent leak detection dyes are specialized chemical compounds added to fluids that flow through pipelines. These dyes are engineered to absorb UV light and re-emit it as visible light, making them highly visible under UV inspection lamps. The application of these dyes in pipeline systems provides an efficient and non-invasive way to detect leaks by marking the locations where fluid is escaping.

When a leak occurs, the dye escapes with the leaking fluid, and under UV light inspection, the dye glows brightly, highlighting the exact location of the leak. This method significantly reduces the time required to identify the leak, saving both time and resources in industrial maintenance operations.

How Do Fluorescent Leak Detection Dyes Work?

The Science Behind Fluorescent Dyes

Fluorescent dyes are typically synthetic organic compounds that have the unique property of fluorescence. Fluorescence is the emission of light by a substance that has absorbed light or other electromagnetic radiation. Fluorescent dyes used in leak detection are designed to absorb ultraviolet (UV) light and re-emit it as visible light, usually in the form of a bright, often neon-like color.

Step-by-Step Process of Leak Detection

- Dye Injection: The fluorescent dye is added to the pipeline fluid, whether it’s water, oil, or gas. This step typically occurs during routine maintenance or prior to a leak detection survey.

- UV Light Exposure: The area around the pipeline is then inspected using a UV light source, such as a UV inspection lamp. When the UV light hits the fluorescent dye, it causes the dye to glow brightly, creating a visible indication of the leak’s location.

- Visual Detection: The technician or engineer uses the UV light to scan the pipeline system. Wherever there is a leak, the dye will be visible under UV light. This provides a clear, quick, and precise indication of the problem area.

- Leak Location: The glowing fluorescence reveals the exact location of the leak, which can then be quickly addressed without needing to dismantle the entire system or conduct invasive tests.

This method is highly effective because it allows for precise leak identification in real-time, even in large or complex pipeline networks.

Why Use Fluorescent Leak Detection Dyes?

- Non-Invasive and Efficient

One of the key advantages of using fluorescent leak detection dyes is their non-invasive nature. Traditional leak detection methods can involve dismantling pipeline sections or conducting expensive and time-consuming pressure tests. With fluorescent dyes, you can identify leaks without disrupting the flow of the pipeline, minimizing operational downtime.

- Fast and Accurate Leak Detection

Leaks can often be small and difficult to detect, especially in large-scale systems. Fluorescent dyes provide a fast and accurate way to pinpoint leaks, even in hard-to-reach areas. This ensures that leaks are detected early, preventing further damage to the system and avoiding costly repairs.

- Cost-Effective Solution

By reducing the need for more expensive or complex testing methods, fluorescent leak detection dyes are a cost-effective solution for industrial pipeline systems. They allow for routine leak inspections and monitoring without the high costs typically associated with pipeline maintenance.

- Improved Safety

In industries dealing with hazardous fluids or gases, detecting leaks promptly is critical for ensuring worker safety and environmental protection. Fluorescent dyes allow for the quick identification of leaks in pipelines, reducing the risk of accidents and environmental damage.

Applications of Fluorescent Leak Detection Dyes

Pipelines Fluorescent Leak Detection Dyes are widely used across various industries, including:

- Oil and Gas: Detecting leaks in pipelines carrying crude oil, natural gas, or refined products.

- Water Treatment: Locating leaks in municipal water supply systems.

- Chemical Industry: Ensuring the integrity of pipelines carrying hazardous chemicals.

- HVAC Systems: Identifying refrigerant leaks in air conditioning and refrigeration systems.

- Manufacturing: Ensuring the safety and efficiency of industrial processes involving fluids and gases.

Each of these industries relies on effective pipeline monitoring, and fluorescent dye technology offers a proven and reliable solution.

Q&A: Fluorescent Leak Detection Dyes

Q1: How do fluorescent leak detection dyes help in industrial pipeline maintenance?

Fluorescent leak detection dyes help identify the precise location of leaks in industrial pipeline systems. By introducing the dye into the pipeline fluid, technicians can use UV light to quickly detect any escaping fluid, allowing them to perform repairs before the problem escalates.

Q2: Are fluorescent leak detection dyes safe to use?

Yes, these dyes are formulated to be safe for use in pipeline systems. They are non-toxic and designed to work within a range of fluids used in industrial processes. However, it’s always important to check the specific safety data sheet (SDS) for the particular dye you are using.

Q3: How long do fluorescent leak detection dyes last in the system?

The duration of the dye’s visibility depends on the type of dye used and the environmental conditions of the pipeline. Most dyes remain visible for a sufficient period to conduct inspections, but the exact lifespan can vary.

Q4: Can fluorescent leak detection dyes be used for all types of pipeline systems?

Fluorescent dyes are versatile and can be used in a wide range of pipeline systems, including those carrying water, oil, gas, and chemicals. However, it’s important to select the appropriate dye for the specific fluid type and system requirements.

Q5: How does UV light aid in detecting leaks?

UV light causes the fluorescent dyes to absorb the radiation and emit visible light. The fluorescence allows technicians to easily spot leaks, as the dye will glow brightly where there is a breach in the pipeline, making it easier to pinpoint the exact location of the leak.

Summary Table: Key Information on Fluorescent Leak Detection Dyes

| Aspect | Description |

| How They Work | Fluorescent dyes glow under UV light when they escape from leaks in pipelines, highlighting leak locations. |

| Key Benefits | Non-invasive, cost-effective, fast, accurate, and enhances safety in industrial pipeline systems. |

| Common Applications | Oil & gas, water treatment, chemical industries, HVAC systems, and manufacturing processes. |

| UV Light Role | UV light causes the dye to fluoresce, making it visible and easy to detect leaks. |

| Safety | Fluorescent dyes are generally non-toxic and safe for use with various pipeline fluids. |

| Cost-Effectiveness | Reduces the need for more expensive and time-consuming leak detection methods. |

Conclusion

Pipelines Fluorescent Leak Detection Dyes provide an essential tool for maintaining the integrity of industrial pipeline systems. With their ability to pinpoint leaks quickly and accurately, these dyes save time, reduce costs, and enhance safety. Whether you’re managing pipelines in the oil and gas industry, chemical manufacturing, or municipal water systems, fluorescent leak detection is a proven and reliable method for ensuring your systems remain leak-free.

At Sunlonge, we specialize in providing high-quality fluorescent dyes for industrial leak detection. Learn more about our products and how they can help improve your pipeline maintenance efforts by visiting Sunlonge’s website.

CN

CN