Introduction

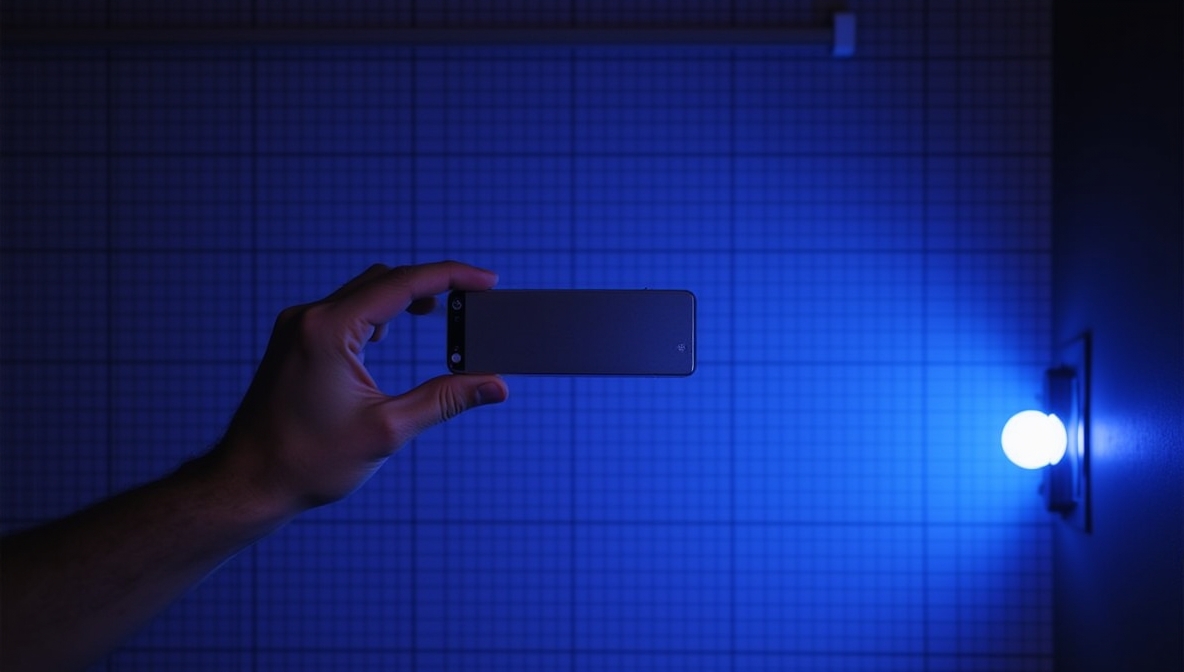

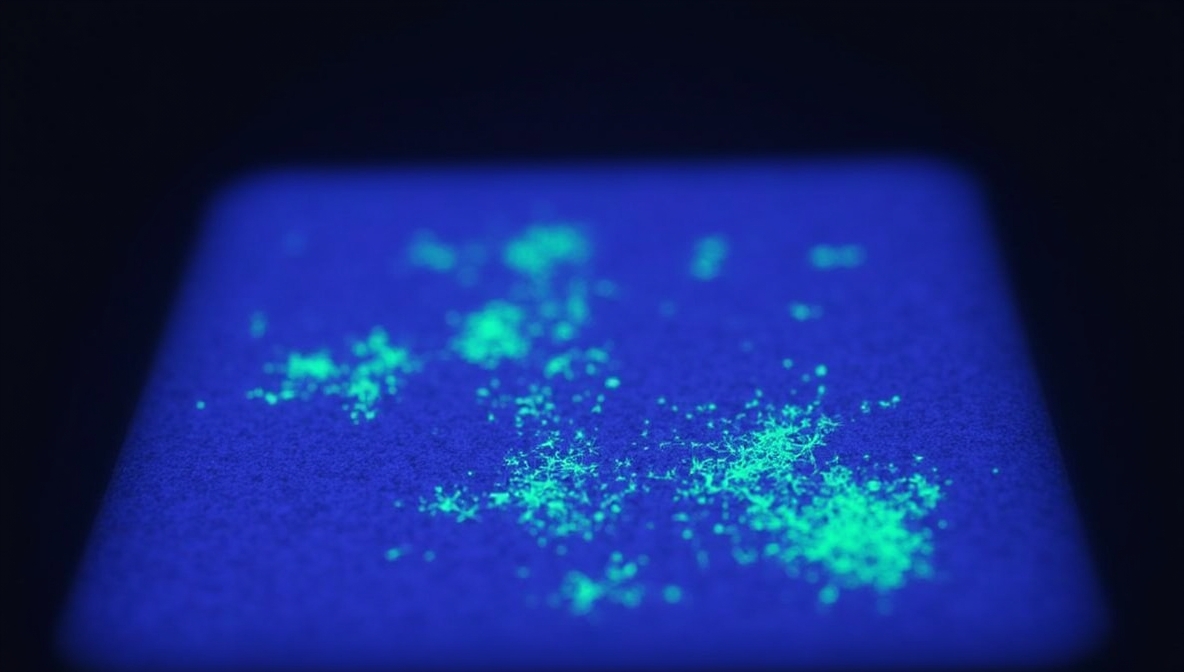

Fluorescent magnetic particle testing (MT) is a cornerstone of non-destructive testing (NDT), widely used to detect surface and near-surface flaws in ferromagnetic materials such as steel and iron. This method involves applying fine magnetic particles coated with fluorescent dyes to a test object. When a magnetic field is applied, these particles gather at areas of flux leakage—indicating cracks, seams, or other discontinuities. To make these indications visible, a high-quality ultraviolet (UV) light source is essential, as it excites the fluorescent particles, causing them to glow brightly against the material’s surface.

The effectiveness of this process hinges on the UV light source. Traditionally, mercury-vapor lamps dominated the industry, but today, UV LED lamps have emerged as a game-changer. Offering superior intensity, precision, and reliability, UV LED lamps enhance the visibility of indications in magnetic particle testing, reducing human error and boosting detection accuracy. In this article, we’ll explore how these advanced lamps improve NDT outcomes, with a spotlight on Sunlonge’s cutting-edge UV LED lamp (available at http://www.sunlonge.com/product/1341.html).

The Evolution of UV Lighting in NDT

For decades, mercury-vapor lamps were the standard for UV illumination in fluorescent magnetic particle testing. These lamps generate UV light by exciting mercury vapor with an electric current, producing a broad spectrum that includes the UV-A range (315-400 nm)—ideal for NDT applications. However, they come with notable limitations:

- Heat Output: Mercury-vapor lamps generate significant heat, which can discomfort inspectors and potentially affect the test environment.

- Short Lifespan: With an operational life of 1,000–2,000 hours, frequent replacements are necessary, increasing downtime and costs.

- Inconsistent Intensity: UV output diminishes over time, leading to variable inspection results.

- Environmental Impact: Containing mercury, these lamps pose disposal challenges due to their hazardous nature.

Enter the UV LED lamp, a modern alternative that addresses these shortcomings. Light-emitting diodes (LEDs) produce UV light efficiently, offering a host of advantages that have driven their adoption across the NDT industry. From energy savings to enhanced durability, UV LED lamps are transforming how magnetic particle testing is performed.

Why UV LED Lamps Excel in Magnetic Particle Testing

The shift to UV LED lamps isn’t just a trend—it’s a leap forward in inspection technology. Here’s how these lamps improve detection accuracy in fluorescent magnetic particle testing:

- High-Intensity Illumination

A UV LED lamp delivers exceptional intensity, often exceeding 5,000 μW/cm² at a distance of 15 inches (38 cm). This high-intensity output makes fluorescent indications brighter and more distinct, enabling inspectors to spot even the tiniest flaws. Enhanced visibility reduces the risk of overlooking defects, directly improving accuracy and reliability.

- Precise Wavelength Control

Fluorescent particles in MT are optimized to fluoresce under UV-A light, typically at 365 nm. Unlike mercury-vapor lamps, which emit a broad spectrum, UV LED lamps can be engineered to emit light at this exact wavelength. This precision maximizes particle fluorescence, sharpening the contrast between indications and the background for clearer, more accurate flaw detection.

- Durability and Consistency

Built for industrial environments, UV LED lamps boast lifespans of up to 25,000 hours or more—far outpacing traditional lamps. Their solid-state design resists shock and vibration, ensuring consistent performance over time. This reliability eliminates fluctuations in UV output, providing stable conditions for repeatable, error-free inspections.

- Energy Efficiency and Low Heat

UV LED lamps consume less power and produce minimal heat compared to their mercury-vapor counterparts. This efficiency not only lowers operational costs but also creates a safer, more comfortable working environment for inspectors, while preventing thermal effects on test objects or particles.

- Portability and Ergonomics

Designed with practicality in mind, many UV LED lamps are lightweight and portable, often featuring ergonomic handles or battery-powered options. This flexibility allows inspectors to maneuver easily around large or complex components, enhancing efficiency without sacrificing accuracy.

- Standards Compliance

High-quality UV LED lamps, like those from Sunlonge, meet rigorous industry standards such as ASTM E3022, which outlines performance requirements for LED UV-A lamps in NDT. Compliance ensures that these lamps deliver the intensity, wavelength, and reliability needed for critical inspections.

By combining these benefits, UV LED lamps minimize human error, ensuring that flaws are detected with precision and consistency—a critical factor in industries like aerospace, automotive, and manufacturing.

Sunlonge’s UV LED Lamp: A Leader in NDT Precision

Sunlonge’s UV LED lamp (http://www.sunlonge.com/product/1341.html) exemplifies how advanced technology can elevate magnetic particle testing. Tailored for NDT professionals, this UV LED lamp integrates the features that matter most:

- High Intensity: Delivering robust UV output, it ensures vivid indications even in challenging conditions.

- 365 nm Wavelength: Perfectly tuned for fluorescent particle excitation, enhancing visibility and contrast.

- Long-Lasting Design: With a durable build and extended lifespan, it reduces maintenance needs and costs.

- User-Friendly Features: Lightweight and ergonomic, it simplifies inspections across diverse applications.

- ASTM E3022 Compliance: Certified for professional use, guaranteeing top-tier performance.

NDT technicians using Sunlonge’s UV LED lamp report improved detection of fine cracks and discontinuities, thanks to its superior illumination and reliability. Whether inspecting welds, castings, or machined parts, this product empowers professionals to achieve unparalleled accuracy.

Q&A: Understanding UV LED Lamps in Magnetic Particle Testing

Q1: What is fluorescent magnetic particle testing?

A: Fluorescent magnetic particle testing is an NDT method that identifies surface and near-surface flaws in ferromagnetic materials. It uses magnetic fields and fluorescent particles, which glow under UV light to reveal defects like cracks or inclusions.

Q2: Why are UV LED lamps critical for this process?

A: UV LED lamps provide the UV-A light needed to activate the fluorescence of magnetic particles. Their high intensity and precise wavelength ensure that flaws are clearly visible, improving detection accuracy.

Q3: How do UV LED lamps differ from traditional UV lamps?

A: Compared to mercury-vapor lamps, UV LED lamps offer higher intensity, longer lifespans (up to 25,000 hours), lower heat output, and consistent performance. They’re also eco-friendly, free of hazardous mercury.

Q4: What features should I prioritize in a UV LED lamp for MT?

A: Look for high intensity (>5,000 μW/cm²), a 365 nm wavelength, durability, portability, and compliance with standards like ASTM E3022. Sunlonge’s UV LED lamp checks all these boxes.

Q5: How does intensity impact detection accuracy?

A: Higher intensity brightens indications, making small or subtle flaws easier to detect. This clarity reduces oversight and enhances the precision of inspections.

Q6: Are there safety precautions with UV LED lamps?

A: Yes, inspectors should wear UV-protective eyewear and clothing to shield against exposure. Testing areas should also be controlled to prevent unintended UV exposure to others.

Key Specifications: UV LED Lamps for Magnetic Particle Testing

| Feature | Sunlonge UV LED Lamp | Typical Competitor A | Typical Competitor B |

| Wavelength | 365 nm | 365 nm | 365 nm |

| Intensity | >5,000 μW/cm² | 4,500 μW/cm² | 4,000 μW/cm² |

| Beam Area | Wide, adjustable | Medium | Narrow |

| Lifespan | ~25,000 hours | ~20,000 hours | ~15,000 hours |

| Power Source | AC/DC or Battery | AC Only | AC Only |

| Compliance | ASTM E3022 | ASTM E3022 | None |

Note: Competitor values are illustrative. Sunlonge’s specifications are based on typical high-quality UV LED lamps for NDT.

Conclusion

In fluorescent magnetic particle testing, accuracy is non-negotiable. The transition from traditional UV lamps to UV LED lamps has revolutionized this process, offering brighter illumination, precise wavelength control, and unmatched reliability. These advancements enhance the visibility of indications, reducing human error and ensuring that even the smallest flaws are detected.

Sunlonge’s UV LED lamp (http://www.sunlonge.com/product/1341.html) stands at the forefront of this evolution, providing NDT professionals with a powerful tool to elevate their inspection processes. Ready to improve your flaw detection accuracy? Visit Sunlonge’s website or contact our team to discover how our UV LED lamp can meet your needs.

CN

CN