Introduction

In modern industrial manufacturing, quality assurance has never been more critical. From aerospace components to automotive systems, semiconductor wafers to medical devices, the ability to detect microscopic defects can be the difference between a product that meets the highest standards and one that poses safety risks. At the heart of this inspection capability lies a technology that has revolutionized non-destructive testing (NDT): the UV LED lamp, specifically its beam intensity and uniformity characteristics.

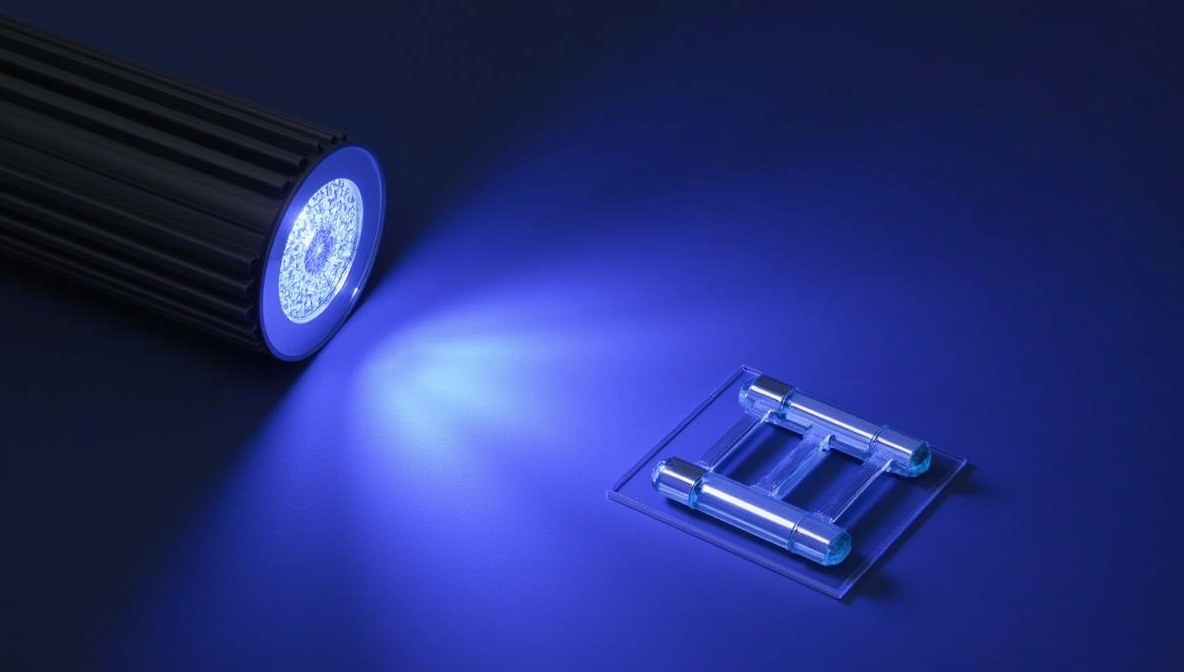

The SL6300 Adjustable UV Flashlight and Sunlonge’s comprehensive UV inspection solutions represent the cutting edge of this technology. But what exactly makes beam intensity and uniformity so critical for industrial inspections? This article explores the physics, applications, and practical advantages of understanding UV LED beam characteristics in fluorescent penetrant testing (FPI), magnetic particle inspection (MPI), quality control (QC), and wafer inspection applications.

Understanding UV LED Beam Intensity: The Foundation of Reliable Inspections

What is UV Beam Intensity and How is it Measured?

UV beam intensity refers to the concentration of ultraviolet radiation energy striking a surface within a specific area, typically measured in microWatts per square centimeter (µW/cm²) or lux. This metric is fundamental because it directly determines the strength of fluorescence that penetrants, magnetic particles, or surface contaminants will emit when exposed to UV light.

The intensity is measured at a standardized working distance, most commonly 15 inches (380mm) or 30cm, which establishes a consistent reference point for all measurements and comparisons. The industry recognizes that intensity is inversely proportional to the square of the distance from the light source—meaning if you double the distance, the intensity drops to one-quarter of its original value.

For example, Sunlonge’s SL6300 UV flashlight delivers 35,000 µW/cm² at 15 inches (380mm), providing substantial irradiance for fluorescent detection applications. In contrast, high-performance wafer inspection systems like the SL8100 deliver up to 400,000 lux at 30cm, enabling detection of particles as small as 1 micrometer.

Why Peak Wavelength Matters for Beam Effectiveness

The effectiveness of UV beam intensity is inseparable from wavelength selection. The industry standard for fluorescent penetrant and magnetic particle testing is 365 nanometers (nm), falling within the UV-A spectrum (360-370nm). This wavelength range was established because:

- Optimal Fluorescence Activation: Traditional penetrant and magnetic particle materials were formulated to fluoresce maximally when excited by 365nm UV light—the emission line of mercury-vapor lamps that dominated the industry for decades.

- Deep Penetration: The 365nm wavelength penetrates deeper into materials compared to shorter UV wavelengths, making it ideal for subsurface defect detection in clear or lightly pigmented materials.

- Minimal Visible Light Contamination: The 365nm wavelength produces minimal visible light (deep violet glow barely perceptible to the human eye), maintaining inspection contrast in dark environments—a critical requirement for sensitive defect detection.

Sunlonge’s UV LED products strictly maintain the 365-370nm peak wavelength, ensuring optimal compatibility with fluorescent materials while minimizing visible light emission (less than 2 FC / 20 lux with black light filters in the SL6300 Standard Version).

Industry Standards and Irradiance Thresholds

The ASTM E3022 standard, the benchmark specification for LED UV-A lamps in fluorescent penetrant and magnetic particle testing, establishes clear irradiance requirements:

- Minimum intensity: 1,000 µW/cm² at 15 inches (required baseline)

- Recommended range: 1,000 to 4,500 µW/cm² at 15 inches

- Upper threshold: Below 10,000 µW/cm² (intensities above this level risk fading fluorescent dyes and reducing inspection effectiveness)

Additional standards that govern UV lamp performance include:

- ISO 3059: Viewing conditions for penetrant and magnetic particle testing

- Rolls-Royce RRES 90061: Aerospace-specific requirements for LED UV sources

- ASTM E1417, E1444, E709, E2297, E3022: Comprehensive NDT testing standards

- Airbus AITM6-1001: Aviation industry testing methods

- AMS2647F: Aerospace material specifications

These standards exist because proper irradiance directly correlates with inspection reliability, repeatability, and safety.

Beam Uniformity: The Often-Overlooked Factor Determining Inspection Quality

Why Uniform Beam Distribution Matters

Beam uniformity describes how evenly UV intensity is distributed across the illuminated surface. This is distinctly different from peak intensity—you can have a very bright light source, but if that brightness is concentrated in a small spot with dark areas around it, inspection quality suffers dramatically.

Non-uniform beams create “shadowing effects”—areas of inadequate irradiance where fluorescent indications become invisible or faint. This directly results in:

- False negatives (missed defects that should have been detected)

- Inconsistent inspection results (the same defect appearing bright in one spot, invisible in another)

- Reduced inspection speed (inspectors must adjust lamp position repeatedly to achieve adequate lighting)

- Higher operator fatigue (constant searching and repositioning leads to inspection errors)

Research published in scientific literature demonstrates that maximum uniformity(measured as standard deviation in irradiance across the illuminated area) occurs at specific working distances, typically 15-20mm for LED arrays. However, industrial NDT applications require working distances of 300-500mm or more, creating inherent uniformity challenges that quality lamp designers must overcome.

Achieving Beam Uniformity: Technical Approaches

Modern UV LED manufacturers employ several techniques to achieve superior beam uniformity:

- Precise LED Array Design: Calculating optimal spacing, number, and arrangement of individual LED elements to create overlapping light patterns that merge into a uniform field at the working distance.

- Advanced Optical Lenses and Diffusers: Using specialized optical elements that shape and distribute the light from individual LEDs, reducing the “holes” in coverage between LED elements.

- Reflective Cup Design: Engineering reflector geometries that capture and redirect light, expanding the illuminated area while maintaining even distribution.

- Working Distance Optimization: Establishing minimum working distances where individual LED beams overlap sufficiently to create uniform coverage.

The Sunlonge SL6300 adjustable zoom feature exemplifies advanced uniformity control, allowing users to adjust the focal length and irradiated area from 30-100mm diameter at 38cm distance. This adjustability ensures that different inspection tasks—from tight aerospace components to large automotive surfaces—can achieve optimal uniformity for their specific requirements.

Industrial Applications Where Beam Intensity and Uniformity Create Competitive Advantage

- Non-Destructive Testing (NDT) in Aerospace

The aerospace industry represents one of the most demanding UV inspection applications. Aircraft components experience extreme stresses, vibrations, and environmental conditions that can create microscopic cracks, corrosion, and material fatigue—defects that could compromise aircraft safety.

Application Requirements:

- Detection of fatigue cracks in landing gear, wing root components, and fuselage panels

- Inspection of bonded joints and adhesive integrity

- Identification of corrosion and stress corrosion cracking in critical structures

Why Beam Characteristics Matter:

- Aerospace components have complex geometries with hard-to-reach areas requiring focused, intense beams

- Regulations (particularly Rolls-Royce RRES 90061) demand precise irradiance and wavelength specifications

- False negatives are unacceptable—missing a structural crack could result in catastrophic failure

Sunlonge Advantage: The SL6300-Aerospace RRES90061 version meets the world’s most stringent aerospace NDT requirements, delivering 3,500 µW/cm² intensity while maintaining Rolls-Royce compliance. The constant current driver ensures UV intensity remains stable even as battery power diminishes, guaranteeing consistent inspection performance throughout a work session.

- Fluorescent Penetrant Testing (FPI) in Automotive Manufacturing

In automotive production, leak detection represents a critical quality control step. Fuel systems, coolant circuits, and hydraulic lines must be absolutely leak-free. Fluorescent penetrant testing, enhanced by high-intensity UV lamps, provides rapid, non-destructive leak detection.

Application Requirements:

- Rapid screening of hundreds of components per production shift

- Detection of micro-leaks (0.5-1mm cracks) that visual inspection might miss

- Consistency across multiple inspection operators and shifts

- Cost-effective inspection that doesn’t damage components

Why Beam Characteristics Matter:

- Uniform, intense light enables rapid scanning of large surface areas

- High irradiance reveals even faint fluorescent indications in good lighting conditions

- Consistent beam quality reduces false positives and false negatives

Inspection Impact: Studies cited by Quality Magazine demonstrate that implementing proper UV inspection in automotive manufacturing can reduce defect rates by up to 30%, directly improving product reliability and safety.

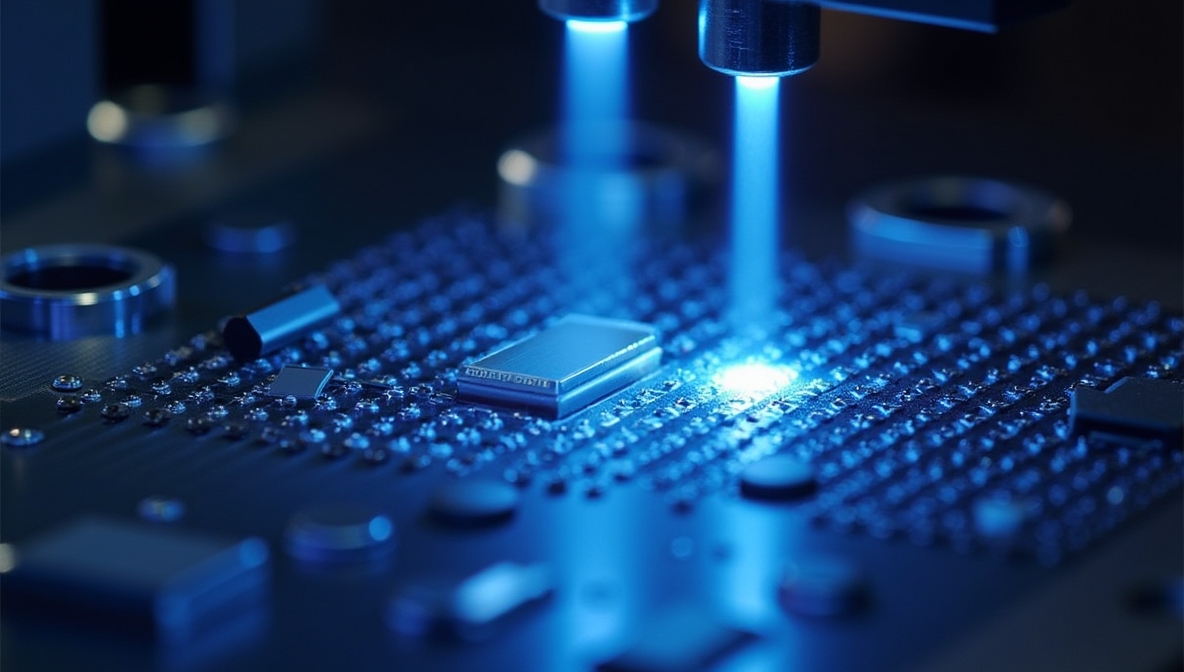

- Wafer and Semiconductor Inspection

Modern semiconductor manufacturing requires detection of increasingly minute defects. Dust particles, residue, scratches, and cracks at the 1-2 micrometer scale can cause chip failures.

Application Requirements:

- Detection of particles as small as 1 micrometer on wafer surfaces

- Inline, real-time inspection during manufacturing flow

- Non-contact, non-destructive analysis (no damage to expensive wafers)

- High throughput to support high-volume fabs

Why Beam Characteristics Matter:

- Extreme irradiance (Sunlonge’s SL8100 provides 150,000-400,000 lux at 30cm) is necessary to make ultra-fine particles visible

- Parallel beam technology (Sunlonge’s core patent) ensures uniform illumination across large wafer surfaces

- Consistent intensity and uniformity enable reliable automated defect detection systems

Competitive Advantage: Sunlonge’s SL8100 wafer inspection lamp outperforms industry standards significantly:

- Industry Standard: 20,000-40,000 lux

- Sunlonge SL8100: 150,000-400,000 lux at 30cm

- LED Lifetime: >30,000 hours

- Wavelength: Optimized 365nm for fluorescence

This represents a 4-10x intensity advantage over conventional systems, enabling faster inspection speeds and detection of defects that would be invisible under standard lighting.

- Quality Control (QC) and Forensic/Security Inspection

Beyond manufacturing, UV LED inspection finds critical applications in forensic analysis, document authentication, and security verification.

Application Requirements:

- Detection of counterfeit security features, hidden markings, and alterations

- Rapid on-site analysis in law enforcement and investigative contexts

- Documentation of evidence in forensic examinations

- Portability and cordless operation for field deployment

Why Beam Characteristics Matter:

- High, consistent irradiance ensures reliable fluorescence detection in varied environments

- Portable, handheld design (like the SL6300) enables rapid investigation without fixed infrastructure

- Long battery life (2.5 hours continuous operation on the SL6300) supports extended field work

Technical Performance Comparison: Sunlonge UV LED Solutions vs. Conventional Alternatives

Mercury-Vapor Lamps vs. Modern UV LED Technology

For decades, mercury-vapor lamps dominated industrial UV inspection. While they achieved adequate irradiance, they presented significant limitations:

| Factor | Mercury-Vapor Lamps | Sunlonge UV LED Solutions |

| Warm-up Time | 5-15 minutes to reach full intensity | Instantaneous—full intensity immediately upon activation |

| Intensity Stability | Decreases gradually as bulbs age | Maintained at 85%+ stability with constant current driver |

| Lifespan | 1,000-3,000 hours | 30,000+ hours (10-30x longer) |

| Power Consumption | 100-400W (mercury systems) | 5-12W (LED handheld units) |

| Environmental Impact | Contains mercury—hazardous disposal required | Mercury-free, environmentally safe |

| Operating Heat | Significant heat emission—requires cooling | Minimal heat, cooler operating environment |

| Shock Sensitivity | Fragile—prone to breakage in harsh environments | Rugged, shock-resistant design |

| Wavelength Precision | Single emission line (365.4nm) | Precisely engineered peak at 365-370nm |

| Efficiency | Lower wall-plug efficiency | Higher energy-to-light conversion efficiency |

Safety and Health Impact: According to OSHA data, chemical exposure incidents in inspection operations decrease by approximately 30% when UV-LED lamps replace mercury systems, primarily because mercury elimination removes hazardous vapor and disposal concerns.

The Physics of Irradiance Strength and Intensity Distribution

Understanding Irradiance as a Critical Quality Metric

Irradiance strength is measured in microwatts per square centimeter (µW/cm²), representing the optical power (energy per unit time) incident on a surface per unit area. This metric is crucial because:

- Fluorescence is a Threshold Phenomenon: Fluorescent dyes require a minimum irradiance to emit visible light. Below the threshold (typically 1,000 µW/cm² for industrial NDT), indications remain invisible.

- Photobleaching Limits Upper Bounds: Excessive irradiance (above 10,000 µW/cm²) can cause rapid fading of fluorescent dyes, reducing the visible lifetime of indications and potentially missing defects if indications fade too quickly.

- Consistency Enables Reliability: Maintaining stable irradiance throughout a battery discharge cycle or operational shift ensures that inspection sensitivity doesn’t vary—the same defect produces the same brightness regardless of when it’s inspected.

Petri Factor and Inspection Uniformity

In scientific and industrial practice, the Petri factor describes the relationship between peak irradiance (measured at the beam center) and average irradiance across the illuminated area. A Petri factor of 1.0 indicates perfect uniformity—all areas receive identical intensity.

In practice, real lamps have Petri factors between 1.2 and 3.0, meaning the center of the beam is 20-300% brighter than the average. Sunlonge’s advanced optical designs minimize Petri factors, ensuring that dim areas of the beam still provide adequate irradiance for reliable defect detection.

Why Sunlonge Products Deliver Superior Performance: Technical Patents and Certifications

Core Technology Innovation: Parallel Light Technology

Sunlonge’s fundamental competitive advantage derives from proprietary parallel light technology, explicitly referenced in company documentation as “core technology” that enables adjustment of UV intensity to meet diverse customer requirements.

This patented approach ensures that:

- Beam divergence is minimized, maintaining intensity across larger distances

- Light distribution is highly uniform, reducing shadowing effects

- Scalability is achieved, allowing Sunlonge to offer products ranging from 150,000 lux to 400,000 lux depending on application requirements

This represents a significant technical achievement because achieving uniformity at extreme intensities is inherently difficult—concentrating 400,000 lux in a defined area while maintaining uniform distribution across the entire illuminated region requires sophisticated optical engineering.

Certifications and Compliance Excellence

Sunlonge products exceed industry standards across multiple domains:

Standards Compliance:

- ✓ ASTM E1417 (Magnetic particle inspection)

- ✓ ASTM E1444 (Penetrant inspection)

- ✓ ASTM E709 (Ultrasonic inspection)

- ✓ ASTM E2297 (Equipment calibration)

- ✓ ASTM E3022 (LED UV-A lamp specifications—the primary standard for modern UV LED inspection)

- ✓ EN ISO 3059 (Viewing conditions for NDT)

- ✓ Rolls-Royce RRES 90061 (Aerospace-specific LED UV source requirements)

- ✓ Airbus AITM6-1001 (Airbus NDT methods)

Aerospace Qualification: The SL6300-Aerospace RRES90061 variant specifically meets Rolls-Royce requirements, the world’s most stringent aerospace UV lamp specification. This certification is extraordinarily difficult to achieve and represents validation by the industry’s most demanding quality arbiter.

Proven Use Cases and Industry Recognition

Sunlonge solutions are deployed across:

- Aerospace Manufacturing: Aircraft component inspection, landing gear testing, wing structure analysis

- Automotive Production: Leak detection in fuel and coolant systems, structural crack inspection

- Semiconductor Manufacturing: Wafer surface inspection, defect detection at micrometer scales

- Electronics Manufacturing: PCB inspection, component adhesion verification

- Forensic and Security Applications: Document authentication, counterfeit detection, evidence analysis

- Medical Device Manufacturing: Quality assurance in sterile component production

The diversity and criticality of these applications underscore Sunlonge’s technical credibility in UV LED inspection solutions.

Practical Selection Criteria: Choosing the Right UV LED Lamp for Your Application

When selecting UV LED inspection equipment, consider these critical factors:

- Wavelength Specification

- Requirement: Peak wavelength between 360-370nm (365nm optimal)

- Why it Matters: Ensures optimal fluorescence activation in all standard penetrant and magnetic particle materials

- Sunlonge Advantage: All products maintain precise 365-370nm specification

- Irradiance and Working Distance

- Requirement: Minimum 1,000 µW/cm² at working distance; 1,000-4,500 µW/cm² recommended range

- Why it Matters: Adequate brightness for reliable defect detection without photobleaching

- Sunlonge Advantage: SL6300 delivers 4,000-35,000 µW/cm² at 15 inches; SL8100 exceeds 400,000 lux

- Beam Uniformity and Distribution

- Requirement: Even coverage of the inspection area; minimal dark spots or dim zones

- Why it Matters: Prevents missed indications due to inadequate local irradiance

- Sunlonge Advantage: Advanced optical engineering minimizes uniformity variance

- Stability and Consistency

- Requirement: UV intensity stability > 85%; variation within ±3% across 30-minute intervals

- Why it Matters: Ensures consistent inspection results regardless of battery state or operational time

- Sunlonge Advantage: Constant current driver technology maintains intensity stability even as battery fades

- Operational Requirements

- Visible Light Emission: Should be minimized (< 2 FC / 20 lux with black light filters)

- Operating Time: Extended battery life (2.5+ hours continuous operation)

- Portability: Lightweight design for field inspection work

- Compliance: Certifications matching your industry requirements

Frequently Asked Questions (Q&A)

Q1: What is the difference between beam intensity and beam uniformity, and why do both matter?

A: Beam intensity measures the brightness (µW/cm²) of the UV light, while beam uniformity describes how evenly that brightness is distributed. Intensity determines whether you have enough light to make defects visible; uniformity ensures that no area of the inspection zone is inadvertently missed due to shadowing. Both are essential—high intensity with poor uniformity still produces inspection blind spots, while uniform but dim illumination may not reveal subtle indications.

Q2: Why is 365nm the standard wavelength for UV inspection lamps?

A: The 365nm wavelength (UV-A range) was selected as the industry standard because: (1) it provides optimal excitation of fluorescent dyes and magnetic particle materials, (2) it penetrates deeper into materials than shorter UV wavelengths, and (3) it minimizes visible light emission, maintaining inspection contrast in dark environments. All standard penetrants and magnetic particle materials are formulated to fluoresce maximally at 365nm.

Q3: Can higher irradiance (beyond 10,000 µW/cm²) improve inspection capability?

A: No—research and industry standards clearly indicate that irradiance above approximately 10,000 µW/cm² causes photobleaching (rapid fading of fluorescent dyes), actually reducing inspection effectiveness. The ASTM E3022 standard recommends maintaining intensity between 1,000-4,500 µW/cm² at 15 inches for optimal performance. Excessive intensity is counterproductive.

Q4: What does “constant current driver” mean, and why is it important?

A: A constant current driver is electronic circuitry that maintains stable UV output as battery voltage decreases during use. Without this, as batteries drain, UV intensity drops proportionally, degrading inspection sensitivity over time. Sunlonge’s SL6300 features a constant current driver, ensuring that a defect detected early in the work shift appears equally bright near the end of the shift—critical for maintaining inspection consistency and reliability.

Q5: How does the SL6300’s adjustable zoom feature improve inspection capability?

A: The SL6300 allows adjustment of the irradiated area from 30-100mm diameter at 38cm distance by adjusting the front lens focus. This enables:

- Large component inspection: Zoomed-out to 100mm diameter for inspecting expansive surfaces rapidly

- Detailed defect analysis: Zoomed-in to 30mm diameter for examining suspected defects with maximum intensity concentration

- Flexible field inspection: Single lamp adaptable to diverse component geometries without requiring multiple tools

Q6: What is “parallel light technology,” and what competitive advantage does it provide?

A: Parallel light technology refers to optical engineering that minimizes beam divergence—the spreading of light as it travels from the source. This proprietary Sunlonge approach ensures that UV intensity remains high and uniform even at considerable working distances. This enables Sunlonge to achieve extreme irradiance values (up to 400,000 lux in the SL8100) while maintaining uniformity—technically challenging and rarely achieved by competitors.

Q7: Why is Rolls-Royce RRES 90061 compliance significant?

A: Rolls-Royce RRES 90061 represents the world’s most demanding aerospace UV lamp specification. Rolls-Royce (a leading aerospace engine manufacturer) imposes this standard to ensure that UV lamps used in aircraft component inspection meet the highest reliability and performance standards. RRES 90061 certification validates that a lamp meets aerospace-grade quality requirements—a distinction most industrial UV lamps cannot claim. Sunlonge’s SL6300-Aerospace RRES90061 variant carries this rare certification.

Q8: How often should UV lamps be calibrated, and why?

A: ASTM E3022 and related standards recommend pre-inspection calibration verification using calibrated UV radiometers before each inspection session or shift. This ensures that irradiance remains within specification (1,000-4,500 µW/cm² at 15 inches). While LED lamps are extremely stable, optical elements can accumulate dust or degradation over time, so periodic verification prevents undetected performance drift.

Q9: Can UV-LED lamps replace mercury-vapor lamps in existing inspection procedures?

A: Yes, with proper validation. Modern UV-LED lamps (particularly those meeting ASTM E3022) are direct replacements for mercury-vapor systems. Key advantages include instant start (no warm-up time), superior efficiency, longer lifespan, and absence of hazardous mercury. However, any equipment change should be validated to ensure irradiance and wavelength specifications are met.

Q10: What is the typical lifespan of UV-LED lamps, and how does it compare to traditional lamps?

A: Sunlonge UV-LED lamps are rated for 30,000+ operating hours, compared to 1,000-3,000 hours for mercury-vapor systems. This represents a 10-30x longer operational life, dramatically reducing replacement frequency and maintenance costs. At typical utilization rates (8 hours per day, 5 days per week), an LED lamp requires replacement approximately once per decade, while mercury systems require replacement every few months.

Recommended Equipment: Sunlonge SL6300 and SL8100 Solutions

SL6300 Adjustable UV LED Flashlight: Versatile Field Inspection

The SL6300 represents Sunlonge’s flagship handheld UV inspection solution, engineered for aerospace, automotive, and general industrial NDT applications.

Technical Specifications:

- Peak Wavelength: 365-370nm (optimal for fluorescence)

- UV Intensity: 4,000-35,000 µW/cm² at 15 inches (380mm)

- Adjustable Beam: 30-100mm irradiated area at 38cm distance (zoom lens)

- LED Configuration: 1 × 5W 365nm UV LED with optical lens and filter

- Battery: 3.7V 2200 mAh 18650 lithium battery

- Operating Time: 2.5 hours continuous

- Stability: > 85% intensity stability with constant current driver

- Visible Light Emission: < 2 FC (20 lux) with black light filters

- Product Dimensions: 150 × 44mm; Weight: 160g without accessories

- Certifications: ASTM E1417, E1444, E709, E2297, E3022; Rolls-Royce RRES 90061; EN ISO 3059

- Standard Package: Flashlight, charger, carry case

Variant: The SL6300-Aerospace RRES90061 version is specifically qualified for aerospace NDT applications with stricter irradiance control and Rolls-Royce compliance validation.

SL8100 Wafer Inspection Lamp: High-Intensity Semiconductor Inspection

The SL8100 addresses the extreme demands of semiconductor wafer inspection, delivering unprecedented irradiance with parallel light technology.

Technical Specifications:

- Peak Wavelength: 365nm (optimized for fluorescence)

- UV Intensity: 150,000-400,000 lux at 30cm (based on configuration)

- Core Technology: Proprietary parallel light technology enabling high uniformity at extreme intensity

- Detection Capability: Particle detection down to 1 micrometer scale

- Non-Destructive: Contact-free analysis ensures no wafer damage

- Competitive Advantage: 4-10x intensity compared to industry standards (20,000-40,000 lux typical)

- LED Lifetime: > 30,000 hours

- Application: Inline, real-time wafer inspection during semiconductor manufacturing

Use Cases:

- Detection of dust particles and organic/inorganic residue

- Surface crack and scratch identification

- Cosmetic defect identification in semiconductor fabs

- High-volume, high-speed inspection in advanced manufacturing

Conclusion: Why UV Beam Intensity and Uniformity Matter for Your Inspection Operations

In an era where manufacturing quality directly determines product reliability, safety, and customer satisfaction, the choice of UV inspection equipment represents a critical investment in quality assurance infrastructure.

UV beam intensity and uniformity are not mere technical specifications—they directly determine:

- Defect detection capability: Whether you catch problematic flaws before they reach customers

- Inspection efficiency: How quickly you can screen components and identify issues

- Operational consistency: Whether inspection results are repeatable and reliable across shifts and operators

- Regulatory compliance: Whether you meet industry certification requirements in aerospace, automotive, and other regulated sectors

- Total cost of ownership: Long-lived LED technology vs. frequent mercury lamp replacement

Sunlonge’s UV LED solutions—from the versatile SL6300 adjustable flashlight to the high-performance SL8100 wafer inspection system—demonstrate how advanced optical engineering, proprietary parallel light technology, and rigorous quality standards converge to deliver superior inspection capability.

When you select a Sunlonge UV LED lamp, you’re investing in:

- Certified performance exceeding ASTM E3022, ISO 3059, and Rolls-Royce RRES 90061 standards

- Proven reliability with 30,000+ hour lifespan, constant current driver stability, and mercury-free operation

- Advanced technology embodied in proprietary parallel light systems enabling extreme uniformity and intensity

- Real-world effectiveness validated across aerospace, automotive, semiconductor, and forensic applications worldwide

The next time you face a critical inspection decision—whether evaluating aerospace component integrity, screening automotive systems for leaks, or inspecting semiconductor wafers for micrometer-scale defects—remember that the quality of your UV light source directly determines the quality of your results. Sunlonge delivers UV inspection technology engineered for industries where precision and reliability are non-negotiable.

Additional Resources and Support

For more information about Sunlonge UV LED inspection solutions, technical specifications, application guidance, or certification documentation:

- Product Information: Visit the Sunlonge website for detailed technical specifications, certifications, and use case documentation

- Consultation Services: Contact Sunlonge technical support for application-specific recommendations

- Training and Calibration: Sunlonge offers training on proper UV lamp operation, irradiance measurement, and inspection best practices

- Standards Compliance: All Sunlonge products include documentation of compliance with relevant ASTM, ISO, and aerospace standards

CN

CN