Introduction

Pipeline failures represent one of the most costly challenges facing industrial facilities worldwide. When a major pipeline rupture occurs, organizations face not only expensive emergency repairs but also extended downtime, environmental liability, and potential safety hazards to personnel. However, a proactive approach using advanced detection technologies can prevent these catastrophic failures before they happen. Pipelines fluorescent leak detection dyes have emerged as the gold standard for early-stage leak identification, enabling maintenance teams to catch corrosion points, micro-cracks, and pinhole leaks long before they escalate into major failures.

This comprehensive guide explores how fluorescent leak detection dyes revolutionize pipeline preventive maintenance, the science behind their effectiveness, and why premium solutions like those from Sunlonge outperform standard alternatives in real-world industrial applications.

Understanding Pipelines Fluorescent Leak Detection Dyes

What Are Fluorescent Leak Detection Dyes?

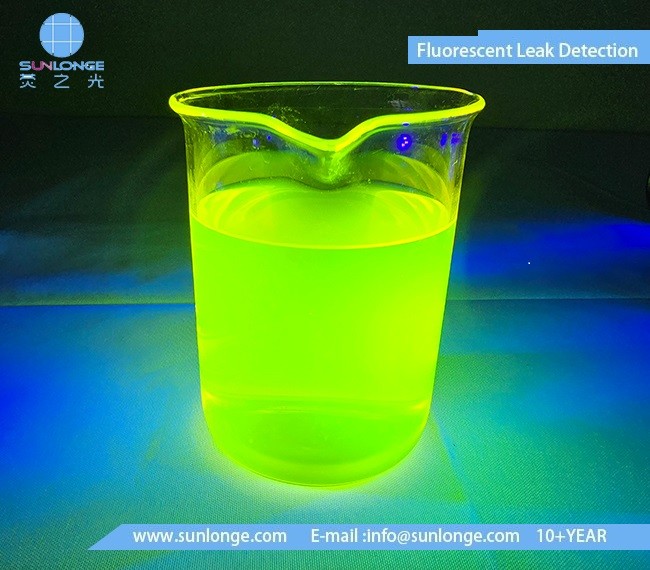

Pipelines fluorescent leak detection dyes are specialized tracer compounds formulated to highlight hidden leaks when exposed to ultraviolet (UV) light. These dyes represent a significant advancement in non-invasive inspection technology, eliminating the need for expensive dismantling, invasive testing, or complex pressure measurements.

Fluorescent dyes work through an elegant photochemical process: when UV light at specific wavelengths (typically 365nm—the standard “black light” designation) illuminates the dye, the dye molecules absorb this ultraviolet energy and re-emit it as visible fluorescent light. This fluorescence creates a distinctive, highly visible glow at leak sites, making even the smallest escape points immediately apparent to trained inspectors.

The brilliance of this approach lies in its simplicity—the dye is introduced into the pipeline fluid during normal system operation, circulates with the fluid, and only becomes visible at locations where leakage has occurred. Unlike traditional inspection methods requiring system shutdown or intrusive access, fluorescent dye detection allows inspectors to maintain operational flow while identifying problems.

How Pipelines Fluorescent Leak Detection Dyes Work: The Step-by-Step Process

The process of detecting leaks with fluorescent dyes follows a straightforward methodology that can be implemented in virtually any industrial pipeline system:

Step 1: Dye Injection

The concentrated fluorescent dye is introduced into the pipeline system, whether it carries water, oil, coolant, refrigerant, or process chemicals. High-quality dyes like Sunlonge’s SL3100 (water-soluble) and SL3200 (oil-soluble) are formulated in highly concentrated formulations, allowing technicians to treat large volumes efficiently. For example, Sunlonge’s SL3100 operates at a 1:3000 dosage ratio, meaning just one liter can treat 3,000 liters of water-based fluid—providing exceptional cost-effectiveness compared to diluted alternatives.

Step 2: System Circulation

Once injected, the dye circulates through the entire pipeline network as an integral part of the system fluid. This circulation period typically lasts 15-30 minutes, allowing the dye to reach all sections of the piping, including hard-to-access areas and complex interconnections.

Step 3: UV Light Examination

Technicians systematically scan the pipeline system using a 365nm UV inspection lamp—a critical component of any comprehensive leak detection program. Premium UV-LED lamps like Sunlonge’s fluorescent leak detection fixtures emit consistent, high-intensity ultraviolet radiation (typically 15,000-21,000 μW/cm²) that reliably triggers fluorescence in quality dye formulations.

Step 4: Visual Detection and Documentation

Wherever leakage is occurring, the escaping dye becomes brilliantly visible under UV illumination, appearing as distinctive glowing spots or streams. Trained inspectors mark these locations for immediate repair, often documenting findings with photographs or video for maintenance records and compliance documentation.

This non-invasive approach preserves system integrity throughout the inspection process, eliminating the operational disruption and safety concerns associated with traditional leak detection methods.

Why Early Leak Detection Saves Money and Enhances Safety

The Financial Impact of Pipeline Leaks: Prevention vs. Repair

Industrial statistics reveal the stark economic reality of undetected leaks. A single unaddressed pinhole leak in a high-pressure pipeline can escalate into a complete rupture within weeks or months, potentially requiring:

- Emergency repair costs: $10,000 to $50,000+ for immediate intervention

- System replacement expenses: $50,000 to $250,000+ for severely corroded sections

- Operational losses: Thousands of dollars per hour in lost production or reduced efficiency

- Environmental remediation: Potentially millions of dollars for hazmat cleanup

- Regulatory fines: Substantial penalties for environmental violations or safety lapses

In contrast, early detection through fluorescent dye inspection enables technicians to address emerging problems through:

- Preventive maintenance: Scheduled repairs of minor leaks at minimal cost ($500 to $2,000)

- Reduced emergency response: Eliminating the need for expensive after-hours emergency services

- Planned downtime: Scheduling repairs during maintenance windows rather than during critical production periods

- Extended equipment lifespan: Preventing secondary damage that would require complete system replacement

Organizations implementing fluorescent leak detection as part of their preventive maintenance protocols typically report 40-60% reductions in total pipeline maintenance costs over a five-year period.

Safety and Environmental Protection

Beyond financial considerations, early leak detection is fundamentally a safety and environmental imperative. Pipelines carrying hazardous fluids—whether pressurized gases, flammable liquids, corrosive chemicals, or toxic substances—present serious risks when leaks occur undetected. These risks include:

- Personnel exposure: Workers in proximity to leaking hazardous materials face health and safety risks

- Environmental contamination: Undetected leaks can result in soil and groundwater pollution

- Regulatory compliance: Organizations must maintain documented evidence of proactive leak prevention programs

- Facility liability: Undetected leaks leading to accidents expose organizations to substantial legal liability

Fluorescent leak detection directly mitigates these risks by enabling rapid identification and repair of leaks before they escalate to hazardous levels. This proactive approach demonstrates due diligence in safety management and environmental stewardship—critical factors in modern industrial operations.

The Science Behind Fluorescent Leak Detection: Understanding Peak Wavelengths and UV-A Light

The 365nm Wavelength Advantage

The standard 365nm wavelength represents the optimal “sweet spot” for fluorescent leak detection applications, and understanding why this wavelength prevails reveals important insights about selecting detection equipment and dyes.

UV light exists across a spectrum of wavelengths, but only certain wavelengths efficiently excite fluorescent dye molecules. The 365nm wavelength—classified as UV-A radiation—offers several distinct advantages:

True UV-A Emission without Visible Light: Lower-quality UV lamps operating at 395nm or longer wavelengths emit a visible violet glow that can interfere with perception of the actual dye fluorescence, reducing contrast and making small leaks more difficult to detect. True 365nm lamps emit pure ultraviolet radiation without visible light interference, enabling superior defect detection.

Maximum Fluorescence Response: Fluorescent dyes are chemically engineered to exhibit peak fluorescence absorption and emission in the 365nm range. This wavelength dependency is not arbitrary—it reflects the quantum mechanical properties of the dye molecules themselves. Using the correct wavelength maximizes the brightness and visibility of fluorescent indicators at leak sites.

Professional Standards Compliance: The 365nm wavelength is specified in multiple international standards for non-destructive testing (NDT), including ISO 9934-3:2015 (magnetic particle inspection) and ISO 3452-4:2013 (penetrant inspection). Organizations using 365nm equipment ensure compliance with regulatory requirements and industry best practices.

Higher Sensitivity: Because 365nm excitation produces maximum fluorescence efficiency, technicians can detect smaller leaks and fainter dye concentrations. This enhanced sensitivity translates directly to earlier problem identification and more comprehensive pipeline surveys.

LED Technology Advantages in UV Lamp Design

The evolution from traditional mercury vapor UV lamps to modern LED-based UV inspection equipment represents a significant technological advancement with important implications for leak detection programs.

Superior Wavelength Precision: LED UV lamps emit light at precisely defined wavelengths (typically within 360-370nm for 365nm devices), whereas traditional mercury vapor lamps emit a broader spectrum with less predictable peak wavelengths. This precision ensures consistent, reliable fluorescence excitation.

Instant-On Operation: Traditional UV lamps required warm-up periods of 5-10 minutes to reach full operating intensity. LED UV lamps achieve peak intensity immediately upon activation, eliminating delays and allowing technicians to begin inspections immediately.

Extended Operational Life: Quality LED UV inspection lamps provide 20,000 to 50,000 hours of continuous operation—approximately 10-50 times longer than traditional mercury vapor alternatives. This extended lifespan significantly reduces equipment replacement costs and improves program reliability.

Enhanced Safety: LED technology is mercury-free, eliminating hazardous chemical exposure risks associated with traditional lamps. OSHA data indicates that organizations using LED UV inspection equipment experience 30% fewer chemical exposure incidents compared to facilities using mercury-based alternatives.

Consistent Intensity Stability: Premium LED UV systems maintain UV intensity stability of 85-95%, with variance typically less than ±3% across extended operating periods. This consistency ensures reliable, reproducible inspection results and reduces the likelihood of missed defects due to insufficient illumination.

Energy Efficiency and Heat Reduction: LED UV lamps consume significantly less electrical power than traditional lamps and generate substantially less waste heat. This reduced thermal output protects sensitive equipment and materials during extended inspection procedures while reducing facility energy consumption.

Portability and Field Application: Modern cordless LED UV inspection lamps with rechargeable batteries enable technicians to conduct comprehensive pipeline surveys in remote locations or areas without convenient electrical access. This portability improves inspection efficiency and enables rapid response to suspected problem areas.

Sunlonge’s Premium Fluorescent Leak Detection Solutions: Technical Excellence and Real-World Performance

Product Overview: SL3100 and SL3200 Formulations

Sunlonge, established in 1999 and headquartered in Hong Kong with manufacturing facilities across mainland China, specializes in advanced UV inspection technology and fluorescent tracer compounds. The company’s two-pronged approach—offering both premium fluorescent dyes and high-performance UV inspection equipment—distinguishes Sunlonge as a comprehensive solution provider rather than a component supplier.

SL3100: Water-Soluble Fluorescent Tracer Dye

Sunlonge’s SL3100 represents the gold standard in water-based leak detection. This concentrated water-soluble formulation contains fluorescein disodium salt suspended in a precisely balanced compound of water and glycol solvent. Key technical specifications include:

- Suitable Detection Wavelength: 365nm (standard NDT black light)

- High Concentration Formula: 1:3000 dosage ratio (1 liter treats 3,000 liters of water)

- Solubility: Fully dissolved in water-based systems; insoluble in petroleum products

- Density: 1.05-1.15 g/cm³ at 20°C

- Flash Point: >100°C (212°F)

- Fluorescence Stability: Excellent fluorescence characteristics and light fastness even in high-pH environments

- Typical Usage Range: 0.3-1.0 ml per liter of test fluid

- Temperature Range: Stable from freezing to moderately elevated temperatures

- Compatibility: Compatible with all rubber, plastic, and metal components; can remain indefinitely in system without degradation

The SL3100 is specifically engineered for antifreeze applications, water tracing in cooling systems, hydraulic fluid surveys, and any water-based industrial circuit where early leak detection is essential. Its superior stability in alkaline environments addresses a critical limitation of standard fluorescein dyes, which can degrade when exposed to pH levels exceeding 8.

SL3200: Oil-Soluble Fluorescent Tracer Dye

For applications involving petroleum-based fluids, Sunlonge’s SL3200 offers unmatched performance. This concentrated solvent-soluble formulation is suspended in a high-flash hydrotreated naphthenic solvent base, engineered for extreme environmental conditions.

Key Technical Advantages:

- Extreme Temperature Stability: Maintains fluorescent properties in environments ranging from -40°C (-40°F) to +400°C (+752°F)

- Chemical Inertness: Formulated as a pure co-solvent-free organic material with no reactive components that might damage system materials

- Compatibility: Compatible with all automotive fluids—engine oil, transmission fluid, power steering fluid, coolants, and brake fluids

- Long-Term System Safety: Does not alter the properties of carrier fluids; can safely remain in vehicle systems indefinitely without performance degradation

- High Concentration Formula: Delivers exceptional cost-effectiveness through efficient dosage rates

- Environmental Compliance: Meets international environmental standards; formulated as biodegradable organic material safe for inspectors and the environment

The SL3200 is the preferred choice for automotive leak detection, industrial hydraulic systems, fuel system inspections, and any application involving petroleum-based fluids operating in challenging thermal or chemical environments.

Sunlonge Fluorescent Leak Detection Lamps: Technical Specifications and Performance Advantages

Beyond providing premium dye formulations, Sunlonge manufactures integrated UV inspection systems that represent the state-of-the-art in leak detection technology.

SL Fluorescent Leak Detection Lamp Series (365nm UV-A LED)

Sunlonge’s flagship UV inspection equipment features:

- LED Configuration: 3 × 5W 365nm UV-A LED array

- UV Intensity Output: 21,000 μW/cm² at the inspection surface

- Wavelength Specification: True 365nm (pure UV-A without visible light interference)

- Optical Design: Advanced lens system with adjustable focal length (20-100mm zoom range)

- Emission Spectrum: Precisely tuned to optimize fluorescence in all Sunlonge dye formulations

- Operational Life: 20,000+ hours of continuous service

- Battery Technology: Rechargeable Li-ion system with visual charge level indication

- Portability: Lightweight construction enabling field inspection without external power

- Safety Features: IP65 rating (dust and water resistant); minimal heat emission; mercury-free design

Technical Innovation: Custom Light Intensity Technology

A distinctive Sunlonge innovation involves their proprietary custom parallel light technology. Rather than offering a single standard intensity option, Sunlonge engineers can deliver customized UV irradiation systems achieving various intensity levels (including models providing 150,000-400,000 lux illumination for specialized applications like wafer inspection). This customization capability ensures that inspection equipment precisely matches application requirements, eliminating situations where standard equipment proves inadequate for specific industrial environments.

Integrated Fluorescence Adapter Solutions

For applications requiring microscopic analysis or integration with laboratory equipment, Sunlonge offers specialized adapters:

- SLF6300: Microscope fluorescence adapter for stereo microscope integration

- SLF8806: Dual-wavelength fluorescence excitation light source for advanced analytical work

These accessories enable Sunlonge customers to extend fluorescent leak detection technology into laboratory verification, materials analysis, and advanced quality control applications.

Why Sunlonge Products Outperform Competitive Alternatives

Several factors position Sunlonge’s offerings as superior to competing leak detection solutions:

- Integrated Product Ecosystem

Unlike competitors offering only dyes or only UV lamps, Sunlonge provides comprehensive solutions—customers can optimize both detection fluid and illumination equipment from a single vendor with deep expertise in both domains. This integration ensures superior compatibility and performance. - Proprietary Dye Formulations

Sunlonge’s research and development team has engineered fluorescent dyes specifically optimized for 365nm UV-A detection. The company’s formulations demonstrate superior fluorescence intensity, temperature stability, and environmental compatibility compared to generic industrial dyes. This proprietary advantage is particularly evident in the SL3200’s ability to maintain functionality across a -40°C to +400°C temperature range—a capability not commonly found in competitor formulations. - High-Concentration Formulas

The 1:3000 dosage ratio of Sunlonge’s SL3100 represents one of the most economical water-soluble dyes available. Typical competitor products operate at ratios of 1:1000 to 1:2000, requiring 1.5-3 times higher volumes for equivalent coverage. This concentration advantage translates directly to reduced chemical cost and simplified handling for maintenance technicians. - Advanced LED UV Technology

Sunlonge’s custom parallel light technology and proprietary intensity tuning capabilities provide flexibility not available from manufacturers offering only standard-intensity equipment. Organizations can specify inspection equipment precisely matched to their specific application requirements. - Comprehensive Testing and Certification

Sunlonge’s dyes and UV equipment undergo rigorous testing to ensure compliance with international non-destructive testing standards. The company’s product data sheets and technical documentation reflect scientific rigor and transparency about performance specifications. - 25+ Years of Industrial Experience

Established in 1999, Sunlonge has witnessed the evolution of leak detection technology across multiple industrial cycles. This extensive operational history in manufacturing and field deployment has informed continuous product refinement and optimization. - Environmental and Safety Commitment

Sunlonge fluorescent dyes are formulated as biodegradable organic materials compliant with international environmental standards. The company’s mercury-free UV lamp designs eliminate hazardous chemical exposure risks, supporting modern organizations’ environmental, health, and safety (EHS) commitments.

Applications of Fluorescent Leak Detection Dyes in Industrial Pipeline Systems

Oil and Gas Refining Operations

The oil and gas industry represents one of the most demanding application environments for leak detection technology. Refineries operate high-pressure pipelines carrying hydrocarbon products at elevated temperatures, where even minor leaks can escalate rapidly. Fluorescent leak detection using oil-soluble dyes like SL3200 enables refineries to:

- Identify pinhole corrosion before catastrophic rupture occurs

- Maintain continuous production while conducting systematic leak surveys

- Document compliance with environmental regulations

- Reduce emergency response costs and production interruptions

Large refineries conducting routine maintenance surveys on complex piping networks often identify 5-15 previously undetected small leaks during comprehensive fluorescent dye inspections. Early detection and repair of these developing problems prevents costly shutdowns and environmental incidents.

Water Treatment and Municipal Systems

Municipal water authorities and commercial water treatment facilities benefit significantly from fluorescent leak detection technology. Water-soluble dyes like SL3100 enable technicians to:

- Identify leaks in distribution systems where visible inspection is impractical

- Detect corrosion-induced pinhole leaks in buried piping

- Monitor system integrity in complex interconnected networks

- Prevent water loss that increases operational costs and environmental strain

A typical medium-sized municipality implementing regular fluorescent dye inspections can identify and address 20-30 hidden leaks annually, reducing non-revenue water loss by 3-5% and preventing major pipe failures in critical distribution infrastructure.

HVAC and Refrigeration Systems

Commercial air conditioning and refrigeration systems operate with sealed refrigerant circuits where even microscopic leaks can compromise system efficiency. The hermetic nature of these systems makes visual inspection impossible, making fluorescent leak detection essential for:

- Identifying refrigerant loss before system performance degradation occurs

- Locating leaks in inaccessible compressor connections and internal heat exchanger lines

- Maintaining EPA compliance for refrigerant accountability

- Preventing efficiency loss and environmental emissions

HVAC technicians using fluorescent dye detection can typically service refrigeration systems 30-40% faster than traditional pressure-drop testing, reducing customer downtime and improving service profitability.

Automotive and Heavy Equipment Maintenance

The automotive aftermarket represents one of the largest applications for fluorescent leak detection dyes. Both dealership service departments and independent repair facilities use oil-soluble fluorescent dyes to:

- Locate elusive engine oil leaks affecting gaskets and seals

- Identify transmission fluid leaks in automatic transmission systems

- Detect coolant loss in water jacket systems

- Find power steering fluid leaks in steering systems

- Identify brake fluid leaks in hydraulic brake systems

Sunlonge’s SL3200 formulation is particularly well-suited for automotive applications due to its compatibility with all common automotive fluids and its exceptional stability across the wide temperature ranges experienced in engine compartments.

Chemical Manufacturing and Process Industries

Chemical plants operating complex piping systems carrying corrosive, toxic, or hazardous process fluids depend on leak detection for both safety and regulatory compliance. Fluorescent dye inspections enable:

- Early identification of corrosion-induced leaks in acid, caustic, and solvent systems

- Compliance documentation for environmental and safety regulations

- Systematic monitoring of critical process lines

- Prevention of hazardous chemical exposure incidents

HVAC Systems in Commercial Buildings

Large commercial buildings with extensive HVAC piping networks benefit from regular fluorescent leak detection surveys. These inspections:

- Identify refrigerant losses that reduce cooling/heating efficiency

- Prevent emergency failures during peak demand periods

- Support energy efficiency initiatives by maintaining system integrity

- Reduce emergency service costs

Comprehensive Q&A: Understanding Fluorescent Leak Detection Dyes

General Knowledge Questions

Q1: How do fluorescent leak detection dyes help in industrial pipeline maintenance?

Fluorescent leak detection dyes identify the precise location of leaks in industrial pipeline systems by introducing colored tracer compounds into the pipeline fluid. When technicians use UV light (typically 365nm wavelength) to scan the system, any escaping dye becomes brilliantly visible, allowing them to pinpoint leaks even in complex piping networks. This non-invasive inspection method enables maintenance teams to perform repairs before small leaks escalate into major failures, saving substantial costs and preventing environmental damage.

Q2: What is the difference between water-soluble and oil-soluble fluorescent dyes?

Water-soluble dyes like Sunlonge’s SL3100 are specifically formulated for water-based systems, antifreeze coolants, and hydraulic fluids in water-glycol base oils. Oil-soluble dyes like SL3200 are engineered for petroleum-based fluids including engine oil, transmission fluid, diesel fuel, and naphthenic-base hydraulic oils. Selecting the appropriate dye type is critical—using oil-soluble dye in a water-based system will result in precipitation and ineffective detection, while water-soluble dye in an oil-based system will separate and fail to circulate properly through the system.

Q3: How long does the fluorescent dye remain visible in a pipeline system?

High-quality fluorescent dyes like those manufactured by Sunlonge remain visible and effective for extended periods—typically 100+ hours of continuous system operation. The dye does not degrade or lose fluorescence when exposed to normal operating temperatures and pressures. After inspection is complete, the dye can safely remain in the system indefinitely without affecting fluid properties or system component compatibility. Many facilities maintain trace quantities of fluorescent dye in circulation for ongoing system monitoring.

Q4: Is fluorescent dye safe for use with all types of pipeline fluids?

Quality fluorescent dyes like Sunlonge’s formulations are specifically engineered to be compatible with the full spectrum of industrial fluids—water, antifreeze, hydraulic oils, mineral oils, synthetic oils, engine oil, diesel fuel, and numerous specialty process fluids. However, compatibility must be verified for each application. The appropriate dye type (water-soluble or oil-soluble) must be selected based on the carrier fluid composition. Once the correct dye type is selected, these compounds are non-corrosive, non-damaging to seals and gaskets, and fully compatible with all standard pipeline materials including copper, steel, aluminum, and plastic components.

Q5: What equipment is required to perform fluorescent leak detection?

Fluorescent leak detection requires only two essential components: (1) the fluorescent tracer dye appropriate for your system fluid type, and (2) a 365nm UV inspection lamp. Premium implementations like those offered by Sunlonge integrate high-intensity UV-A LED lamps that provide sufficient illumination for reliable detection in all industrial environments. No complex or expensive equipment is required—the simplicity and accessibility of this technology is one of its primary advantages compared to alternative detection methods.

Q6: Can fluorescent leak detection identify the severity of a leak?

Fluorescent dye inspection visualizes the location of leaks very clearly but does not provide precise quantification of leak rate. A small pinhole and a larger crack may both produce visible fluorescence under UV light. However, experienced technicians can estimate leak severity based on: (1) the intensity and brightness of the fluorescence, (2) the rate at which dye accumulates at the leak site, and (3) the area over which the dye spreads. For precise quantification of leak rate, supplementary pressure-decay or flow measurement techniques can be employed in conjunction with dye detection.

Q7: How often should pipeline systems be inspected using fluorescent leak detection dyes?

Inspection frequency depends on system criticality, operating environment, and historical leak history. As a general framework: non-critical systems should be surveyed annually; systems with history of leaks or corrosion issues should be inspected quarterly; and critical systems with hazardous fluid or high-consequence-of-failure status should be inspected monthly or continuously. Sunlonge’s high-concentration formulations and durable UV equipment make frequent inspections economically practical, enabling organizations to implement aggressive preventive maintenance programs.

Technical and Application Questions

Q8: Why is 365nm the standard wavelength for fluorescent leak detection?

The 365nm wavelength represents the optimal “sweet spot” for exciting fluorescent dye molecules. Fluorescent compounds are engineered with specific molecular structures that preferentially absorb ultraviolet radiation at precisely defined wavelengths. Using the correct 365nm wavelength maximizes fluorescence intensity while eliminating interference from visible light that can occur with longer-wavelength UV sources (395nm and above). The 365nm standard is also specified in international non-destructive testing standards (ISO 9934-3, ISO 3452-4), ensuring regulatory compliance and industry compatibility.

Q9: What are the advantages of LED UV lamps compared to traditional mercury vapor lamps?

Modern LED UV inspection equipment offers multiple advantages over traditional mercury-based alternatives: (1) Instant activation without warm-up period, (2) Extended operational life (20,000-50,000 hours vs. 2,000-5,000 hours), (3) Mercury-free design eliminating hazardous chemical exposure, (4) Precise wavelength control enabling consistent fluorescence, (5) Greater portability through rechargeable battery systems, (6) Reduced heat generation protecting sensitive equipment, (7) Superior energy efficiency reducing operational costs. Organizations transitioning from mercury to LED systems typically recover equipment investment through energy savings and reduced maintenance within 18-24 months.

Q10: How does the Sunlonge SL3100 achieve its 1:3000 concentration ratio?

Sunlonge’s proprietary formulation process produces SL3100 at exceptionally high dye concentration—approximately 3 times higher than typical competitor products. This concentration is achieved through: (1) Optimization of fluorescein disodium salt solubility in the water-glycol solvent base, (2) Precise pH buffering to maintain dye stability in solution, (3) Specialized additive chemistry preventing dye aggregation and self-quenching at high concentration, and (4) Extended quality control testing ensuring consistent concentration across production batches. The result is that one liter of SL3100 can effectively treat 3,000 liters of water-based fluid, compared to 1,000-2,000 liters for typical competitor formulations.

Q11: What makes the SL3200 suitable for extreme temperature applications?

Sunlonge’s SL3200 oil-soluble dye is formulated in a high-flash hydrotreated naphthenic solvent base rather than lighter mineral oils or synthetic oil bases. This carrier fluid remains physically and chemically stable across the extreme temperature range from -40°C to +400°C, and the fluorescent dye molecules are engineered with structural stability preventing thermal degradation at these temperature extremes. The co-solvent-free organic material formulation eliminates reactive components that might decompose or lose fluorescence when exposed to thermal stress. This exceptional thermal range enables SL3200 to function in aerospace hydraulic systems, high-temperature industrial equipment, and other extreme-environment applications where standard fluorescent dyes would fail.

Q12: Can fluorescent leak detection be used in pressurized systems?

Yes, fluorescent leak detection works excellently in pressurized systems and actually provides superior performance compared to unpressurized applications. The pressure in the system drives the leaking fluid (and its dissolved dye) out of the leak site more forcefully, creating more vivid and concentrated dye deposition around the leak location. This enhanced visualization often allows detection of smaller pressure-driven leaks than would be visible in low-pressure or unpressurized systems. Both Sunlonge dyes are engineered to remain stable and maintain their fluorescent properties under the temperature and pressure conditions typical of industrial piping systems.

Q13: How does fluorescent leak detection integrate with existing preventive maintenance programs?

Fluorescent dye inspection integrates seamlessly into preventive maintenance protocols as a non-invasive diagnostic tool that can be applied during routine equipment servicing. Many organizations add fluorescent dye to equipment during regular fluid changes, allowing the dye to accumulate in the system and enabling continuous low-level monitoring. For more intensive surveys, maintenance teams can conduct comprehensive inspections during scheduled maintenance windows without requiring extended downtime. The simplicity of application and minimal equipment requirements enable easy integration into any existing maintenance program, making this technology accessible even to organizations with limited diagnostic budgets.

Q14: What is the environmental impact of fluorescent leak detection dyes?

High-quality fluorescent dyes like Sunlonge’s formulations are engineered as biodegradable organic materials compliant with international environmental standards. These compounds are non-toxic, do not persist in the environment, and pose no risk to aquatic systems if they escape to the environment (though responsible operators minimize any such release). The environmental benefit of fluorescent leak detection far exceeds any minimal environmental impact from the dye itself—by preventing major pipeline failures and environmental contamination, early leak detection using fluorescent dyes protects environmental integrity far more effectively than alternative inspection methods.

Important Information Summary Table

| Aspect | Details |

| Detection Mechanism | Fluorescent dye molecules absorb 365nm UV-A light and emit visible fluorescence at leak sites |

| Key Wavelength | 365nm (UV-A) is the industry standard; pure UV without visible light interference |

| Primary Products | SL3100 (water-soluble) and SL3200 (oil-soluble) fluorescent tracer dyes |

| SL3100 Concentration Ratio | 1:3000 (1 liter treats 3,000 liters of water-based fluid) |

| SL3100 Temperature Range | Stable across normal to moderately elevated temperatures |

| SL3200 Temperature Range | Exceptional stability from -40°C to +400°C |

| Typical Detection Time | 15-30 minutes circulation; visible results immediate under UV light |

| Equipment Required | Fluorescent dye and 365nm UV inspection lamp only |

| UV Lamp Technology | Modern LED-based systems (vs. obsolete mercury vapor) |

| Sunlonge UV Lamp Intensity | 21,000 μW/cm² for standard configurations; customizable to 150,000-400,000 lux for specialized applications |

| Lamp Operational Life | 20,000+ hours continuous operation |

| Safety Profile | Non-corrosive, compatible with all standard pipeline materials and seals |

| Environmental Compliance | Biodegradable, non-persistent, compliant with international environmental standards |

| Cost-Effectiveness | Early detection prevents 40-60% of total pipeline maintenance costs compared to reactive repair |

| Regulatory Standards | Compliance with ISO 9934-3, ISO 3452-4, and international NDT standards |

| Dye Persistence | Remains visible and effective 100+ hours; can remain in system indefinitely without degradation |

| Industry Applications | Oil & gas refining, water treatment, HVAC systems, automotive maintenance, chemical manufacturing, building systems |

How Fluorescent Leak Detection Dyes Improve Pipeline Preventive Maintenance: The Comprehensive Strategy

The Preventive Maintenance Philosophy

Preventive maintenance represents a fundamental shift from reactive, emergency-response approaches to proactive, systematic management. Traditional reactive maintenance waits for equipment failure to occur, then dispatches emergency crews to address the crisis at maximum cost and maximum operational disruption. Preventive maintenance, in contrast, conducts regular inspections to identify developing problems, then schedules repairs during planned maintenance windows before failures occur.

This philosophical difference translates directly to financial performance. Organizations implementing comprehensive preventive maintenance programs consistently achieve:

- 50-70% reduction in emergency repair costs through elimination of after-hours service premiums

- 30-40% extension of equipment lifespan through early intervention preventing cascading damage

- 20-30% reduction in unplanned downtime through elimination of surprise failures during production runs

- Improved product quality and consistency through operation of properly maintained equipment

- Enhanced safety record through proactive identification and correction of hazardous conditions

Fluorescent leak detection dyes are cornerstone technologies enabling this preventive maintenance philosophy by making early problem identification practical, economical, and reliable.

Detection of Early-Stage Leaks: Identifying Problems Before They Escalate

The progression of pipeline failures typically follows a predictable pattern: a small defect (corrosion pit, microcrack, manufacturing defect, or fatigue fracture) develops in the pipe wall. This defect creates an extremely small leak—often just a pinhole or hairline crack—that may produce no visible signs and no measurable system pressure loss. Over days or weeks, the combination of fluid pressure, vibration, thermal cycling, and chemical corrosion causes this tiny defect to enlarge gradually.

During this critical early window, when the defect is still small enough to repair inexpensively, traditional inspection methods often fail to detect the problem. Manual visual inspection cannot identify fluid seepage in the interior of piping insulation or behind pipe lagging. Pressure-drop testing is insensitive to very small leaks that cause negligible measurable pressure loss. Acoustic listening devices require trained personnel and specific environmental conditions to detect the subtle sounds of small leaks.

Fluorescent leak detection dyes excel precisely in this early detection window. Because the method is visual and immediate, it detects the tiniest escape of fluid regardless of leak rate or system pressure. Even a one-drop-per-hour leak becomes immediately visible under UV light, enabling maintenance teams to:

- Schedule repair of the tiny defect at minimal cost before it enlarges

- Plan maintenance during convenient maintenance windows

- Prevent the catastrophic failure that would occur if the defect is left unaddressed

- Eliminate the emergency repair situation entirely through early intervention

Identification of Corrosion Points: Understanding Where Failures Will Develop

Corrosion represents the primary failure mechanism in aging pipeline systems. Water-containing corrosion products accumulate at corrosion pits, and the expanding corrosion pit gradually weakens the pipe wall. Eventually, the localized corrosion creates a perforation point from which fluid escapes under pressure.

The corrosion process is not random—it concentrates at specific locations influenced by fluid chemistry, system temperature, pipe material composition, and local stress concentrations. Smart preventive maintenance identifies not just the leaks that are actively occurring, but the corrosion points where future leaks are likely to develop.

Fluorescent leak detection accomplishes this through:

- Identifying active corrosion sites where corrosion has already progressed to the point of creating small leaks

- Enabling repair before catastrophic failure occurs through replacement of corroded pipe sections

- Documenting corrosion patterns to guide replacement strategy—focusing investment on high-risk piping runs while deferring replacement of low-corrosion-rate sections

- Supporting material selection decisions for pipe replacement—if certain pipe materials consistently show corrosion patterns in a specific environment, alternative materials can be specified for replacement sections

Detection of Micro-Cracks: Preventing Fatigue Failures and Stress-Corrosion Cracking

Fatigue cracks develop in pipelines subjected to vibration, thermal cycling, or pressure pulsation. These microscopic cracks initiate in high-stress regions and grow incrementally with each stress cycle. Stress-corrosion cracking (SCC) represents a particularly insidious failure mechanism where the combination of applied stress and a corrosive chemical environment causes cracking in materials that would not crack under either condition alone.

Both fatigue cracks and stress-corrosion cracks often grow to critical size without external evidence. The crack may develop internally within the pipe wall, escaping visual observation until it finally perforates. Pressure-drop testing often cannot detect very small cracks with minimal leak rate.

Fluorescent dye detection identifies micro-cracks by visualizing the fluid escape at the crack opening. Even cracks too small to cause visible fluid dripping become apparent through the fluorescent dye accumulation pattern under UV light. This early detection enables:

- Targeted repair of cracked pipe sections before complete failure

- Stress analysis and design correction for pipe runs showing repeated cracking

- Material selection optimization to avoid materials susceptible to stress-corrosion cracking in the specific chemical and stress environment

- Operating procedure adjustments to reduce vibration or thermal cycling causing fatigue cracks

Implementation Best Practices: Establishing an Effective Fluorescent Leak Detection Program

Developing a Baseline Survey

The first step in implementing a fluorescent leak detection program involves conducting a comprehensive baseline survey of all pipeline systems. This baseline serves multiple purposes:

- Identifying existing leaks that may have been overlooked by visual inspection or pressure testing

- Establishing baseline corrosion patterns enabling future comparison to assess corrosion rate progression

- Creating a documented record for regulatory compliance and risk management

- Training maintenance personnel on proper inspection techniques and dye application

- Establishing remediation priorities based on leak severity and pipeline criticality

A typical baseline survey of a large industrial facility might identify 15-30 previously unknown small leaks across the piping network. Many of these leaks have been slowly degrading pipe integrity for months or years without detection. Immediate repair of these identified leaks prevents the escalation that would have eventually created emergency situations.

Establishing Inspection Frequency and Scheduling

After the baseline survey, organizations should establish ongoing inspection frequency based on:

- System criticality: High-consequence-of-failure systems warrant more frequent inspection

- Fluid type: Corrosive or hazardous fluids require more intensive monitoring

- Historical leak history: Systems with previous leaks should be monitored more frequently

- Pipe age and material: Older systems or systems with historically problematic materials warrant closer attention

- Environmental conditions: Systems exposed to corrosive environments require more frequent assessment

A practical framework:

- Annual inspection: Appropriate for non-critical systems with good historical performance

- Quarterly inspection: Appropriate for systems with moderate criticality or previous leak history

- Monthly inspection: Appropriate for critical systems or systems with aggressive corrosion environments

- Continuous monitoring: Possible through maintaining trace fluorescent dye concentration in systems, enabling ongoing monitoring without additional chemical additions

Documentation and Trending

Effective preventive maintenance programs document inspection results systematically, enabling trending analysis that reveals emerging patterns:

- Leak location mapping identifying pipe sections with recurring problems

- Leak rate estimation tracking whether identified leaks are growing or remaining stable

- Corrosion progression assessment comparing corrosion pit density and severity to previous inspections

- Material performance evaluation comparing corrosion rates across different pipe material selections

- Maintenance cost tracking correlating inspection frequency with repair costs to optimize inspection intervals

Many organizations implement digital maintenance management systems that centralize this documentation and enable sophisticated trending analysis. This data-driven approach focuses maintenance investment most effectively, ensuring that limited maintenance budgets are directed toward the highest-priority interventions.

Integration with Other Diagnostic Techniques

While fluorescent leak detection excels at identifying where leaks are occurring, it integrates effectively with complementary diagnostic technologies:

- Thermal imaging identifies hot spots indicating accelerated corrosion or friction

- Ultrasonic thickness measurement quantifies remaining pipe wall thickness in areas identified as high corrosion risk

- Pressure decay testing provides quantitative flow rate for identified leaks, enabling repair prioritization

- Vibration analysis identifies mechanical stress or bearing issues causing vibration-induced fatigue cracks

- Chemical analysis of system fluid reveals corrosion products indicating degradation rate and chemical environment changes

This multi-method diagnostic approach provides comprehensive understanding of pipeline system health, enabling optimal maintenance decision-making.

Conclusion: Fluorescent Leak Detection as Essential Infrastructure Maintenance Technology

Fluorescent leak detection dyes represent one of the most effective, economical, and reliable technologies available for pipeline preventive maintenance. By enabling early identification of leaks, corrosion points, and micro-cracks before they escalate into major failures, these systems prevent the costly emergencies, environmental incidents, and safety hazards that plague reactive maintenance approaches.

Organizations transitioning from reactive to preventive maintenance philosophies consistently achieve substantial economic and operational benefits. The non-invasive nature of fluorescent dye inspection, combined with the simplicity of 365nm UV visualization, makes early problem identification practical and economical even for organizations with limited diagnostic budgets.

Sunlonge’s comprehensive product portfolio—combining premium fluorescent dye formulations (SL3100 for water-based systems, SL3200 for oil-based systems) with advanced LED UV inspection equipment—provides organizations with integrated solutions engineered for real-world industrial applications. The company’s 25+ years of experience in UV inspection technology, combined with proprietary innovations in dye concentration and LED wavelength precision, positions Sunlonge as the preferred partner for organizations committed to systematic, data-driven pipeline maintenance.

The investment in fluorescent leak detection capability pays dividends through prevention of emergency repairs, extension of equipment lifespan, reduction of environmental and safety risks, and overall improvement in operational efficiency. For any organization operating industrial pipelines, the implementation of a comprehensive fluorescent leak detection program represents one of the most cost-effective infrastructure investments possible.

CN

CN