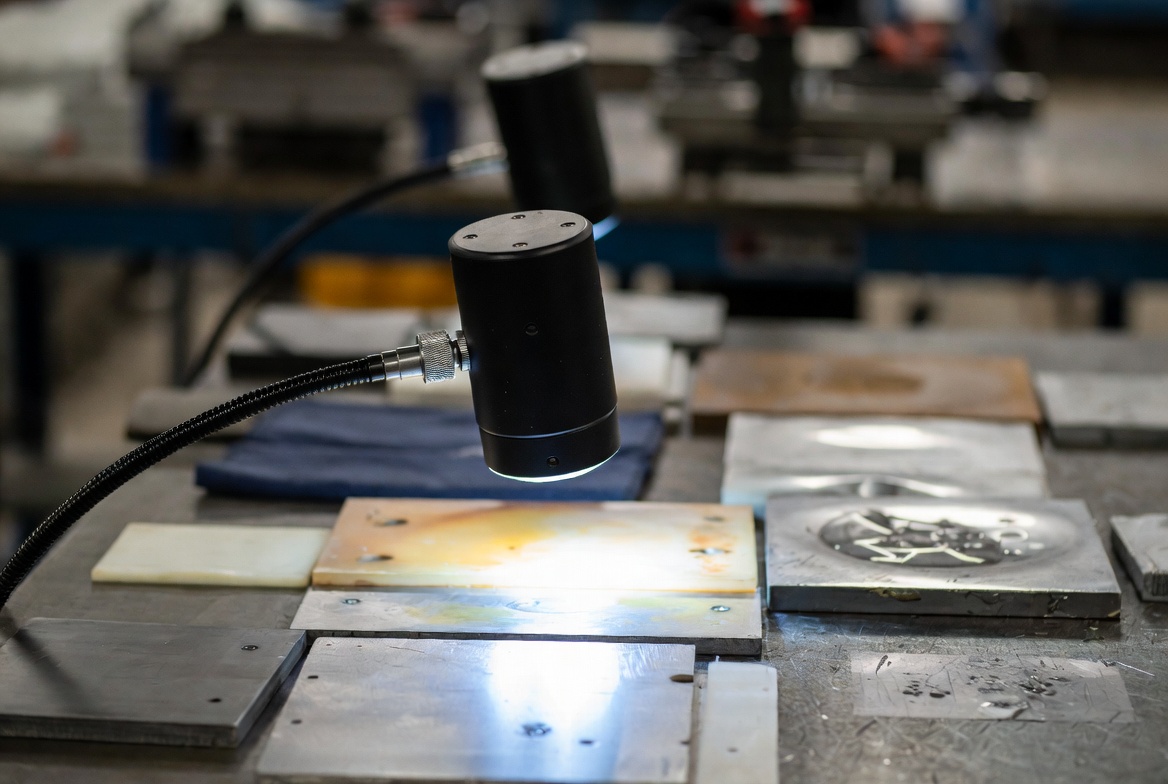

In modern high‑precision manufacturing, the difference between a perfect part and a reject can be a scratch you can barely see, a speck of dust, or a slight coating non‑uniformity. A Surface Inspection Lamp is a specialized high‑intensity LED light source, engineered to make those barely visible defects stand out clearly so operators can catch them in seconds instead of missing them for months. Used correctly, it dramatically improves defect detection on wafers, semiconductors, LCD panels, coated metals, glass, automotive parts, and more.

This article explains what a surface inspection lamp is, how it works, which types of defects it reveals, and how it integrates into visual and automated inspection workflows. It then shows, in practical terms, how Sunlonge’s SL8500 desktop wafer inspection lamp and its related series are designed to outperform typical inspection lights in illuminance, stability, wavelength engineering, and compliance culture—helping you find more defects, faster, with lower operating cost.

What Is a Surface Inspection Lamp?

A surface inspection lamp is a high‑intensity LED lighting device engineered to reveal defects that are difficult—or impossible—to see under normal room or overhead lighting. Unlike generic work lights, these lamps use:

- Carefully selected wavelengths (white, green, yellow, yellow‑green, or UV)

- Customized optical lenses and filters

- High illuminance (lux) at defined working distances

- Optimized beam shape and low‑glare diffusion

to maximize contrast between “good” surface areas and defects such as scratches, dust, pits, coating voids, fingerprints, and micro‑cracks.

Manufacturers use surface inspection lamps in:

- Semiconductor and wafer fabs

- LCD, OLED, and touch panel inspection

- Precision glass and optics

- Coated metals, automotive parts, and painted surfaces

- Ceramic, sapphire, and micro‑engraving molds

In these industries, even a 1 µm particle or hairline scratch can cause downstream failures, yield loss, or visible cosmetic defects in high‑end products. A purpose‑built Surface Inspection Lamp makes those problems obvious, repeatably, and quickly.

How Does a Surface Inspection Lamp Work?

-

High‑Intensity LED Illumination

Modern inspection lamps use powerful LEDs instead of halogen or mercury‑vapor bulbs. This delivers:

- Very high illuminance at close working distances—Sunlonge’s high‑end wafer inspection lamps, for example, reach up to 350,000 lux at 30 cm

- A stable, repeatable light output over thousands of hours of operation

- Cool operation and no hazardous materials (unlike mercury‑vapor bulbs)

High lux levels are essential because they:

- Highlight tiny topographical changes (micro‑scratches, pits)

- Make low‑contrast contamination (dust, fingerprints, oil) clearly visible

- Allow operators to inspect larger areas without moving the workpiece constantly

-

Optimized Wavelengths for Defect Contrast

Different defects “pop” under different wavelengths. Leading manufacturers, including Sunlonge, offer:

- White light (≈6000 K): Excellent for general surface appearance, scratches, overall coating uniformity, and color consistency.

- Green light (≈500–550 nm): Very effective for slight scratches and dust on LCD screens and glass; many defects look darker and sharper against green illumination.

- Yellow / yellow‑green light (≈510–590 nm): Highly effective for micro‑engraving molds, semiconductor wafers, and coatings, where specific scattering and reflection characteristics make defects stand out.

- UV light (365 nm): Used for NDT and fluorescent dye penetrant or magnetic particle testing; cracks and porosity fluoresce strongly under UV.

For example, surface inspection lights like the LUYOR‑3318 series offer yellow, white, green, and UV variants to match different defect profiles across wafers, LCD filters, ceramics, metal surfaces, lenses, and automotive paint. Sunlonge follows the same engineering principle—offering white and green‑yellow versions to tailor detection to your specific materials and defect types.

-

Beam Geometry and Low‑Angle Illumination

Beyond brightness and color, illumination angle is crucial:

- Low‑angle light casts long shadows from tiny height variations, making scratches, pits, and surface waves 10× more visible.

- Even beam profiles prevent bright hotspots and dark zones where defects could hide.

- Dedicated inspection lights for sanding and finishing tasks, like SurfPrep’s LED inspection lights, use low‑angle beams to make surface imperfections extremely easy to see and correct before finishing.

Industrial stroboscopic systems for metals use advanced cross‑light illumination to freeze motion and enhance contrast on fast‑moving steel strips. While Sunlonge’s SL8500 is a continuous lamp rather than a strobe, the underlying principle is the same: the right angle and intensity of light maximize visible contrast between defects and the surrounding surface.

-

Stability and Dimming Control

For reliable inspection and repeatable results, surface inspection lamps must provide:

- High stability: Sunlonge’s wafer inspection series offers light stability greater than 90–95%, minimizing drift over time.

- Infinite dimming: 0–100% dimming lets operators balance contrast and comfort and adjust irradiated area size.

Fine dimming is particularly valuable when switching between highly reflective surfaces (like polished metal or glass) and more absorptive materials (like coatings or ceramics).

What Defects Does a Surface Inspection Lamp Reveal?

A high‑quality Surface Inspection Lamp is designed to expose multiple defect types across many materials:

-

Scratches and Mechanical Damage

- Long and short scratches from handling, slicing, or polishing

- Surface abrasions after sanding, grinding, or lapping

- Micro‑cracks and crazing in glass, coatings, or plastics

Low‑angle, high‑intensity lighting makes these scratches stand out as sharp bright or dark lines because they alter how light is reflected and scattered from the surface.

-

Contamination and Particles

- Dust particles, fibers, and micro‑debris on wafers, LCDs, and optics

- Fingerprints, oil, and smudges

- Foreign matter embedded in coatings or films

Green and yellow‑green surface inspection lamps specifically target dust and contamination on LCD and glass surfaces; photos in competing product literature show dust, fingerprints, and scratches becoming clearly visible under green inspection light. High‑intensity wafer inspection lamps like Sunlonge’s SL8100 can detect dust particles down to 1 µm, making them up to 10× more powerful than traditional inspection lamps.

-

Coating and Paint Flaws

- Uneven coating thickness (thin spots, thick spots, runs)

- Pinholes and voids in coatings

- Color and texture non‑uniformity in automotive paint and decorative finishes

In finishing applications, inspection lights let operators see high and low spots, cracks, splits, and surface imperfections before parts enter the finishing room, reducing rework and customer complaints.

-

Structural and Sub‑Surface Indicators

While a Surface Inspection Lamp is primarily an appearance tool, it plays a key role alongside more advanced inspection systems:

- AOI (automated optical inspection) systems detect scratches, dust, and wiring failures.

- PL (photoluminescence) systems can detect internal wafer defects and emission wavelength variations.

- High‑intensity surface illumination ensures these systems—and human inspectors—start from a clean, high‑contrast visual baseline.

Combining strong surface inspection lighting with PL or image‑based inspection significantly improves the ability to identify micro‑defects that affect performance, such as color unevenness in micro‑LED displays.

Where Are Surface Inspection Lamps Used?

Typical application areas include:

- Semiconductor & wafers: detecting particles, scratches, and coating defects on wafers and photoresist layers

- LCD, OLED, touch panels: highlighting dust, fingerprints, and pixel‑area defects on display glass and filters

- Optics & glass lenses: checking for scratches, chips, and contamination on lenses and photomasks

- Automotive paint and coatings: verifying finish quality and spotting sanding or polishing marks before clear‑coat or delivery

- Metals (steel, aluminum, copper): supporting manual inspection of strip, bar, or coil surfaces, often alongside automated camera‑based systems

- Micro‑engraving molds and precision tooling: ensuring engraved features and edges are free from burrs, chips, dust, and coating anomalies

Sunlonge’s own product lines specifically call out applications in LCD screens, micro‑engraving molds, semiconductors, wafers, sapphires, and coatings—exactly the kind of environments where 1 µm‑scale defects translate into significant yield loss.

Why Sunlonge Surface Inspection Lamps Stand Out

Many vendors offer generic surface inspection lights. Sunlonge differentiates itself in several key areas: illuminance performance, wavelength engineering, optical design, reliability, and compliance mindset.

-

Higher Illuminance for Finer Defect Detection

Many desktop surface inspection lamps on the market deliver around 30,000–60,000 lux at 30 cm. While that’s a big step up from normal room lighting, it can still leave ultra‑fine defects marginally visible.

By contrast:

- Sunlonge’s SL8500 desktop wafer inspection lamp is designed to deliver very high illuminance (up to around 150,000 lux at 30 cm) in a compact desktop form factor, far exceeding typical competing lights in the same size class.

- The larger SL8100 wafer inspection lamp achieves 350,000 lux at 30 cm and 210,000 lux at 40 cm, while maintaining light stability above 95%.

This kind of intensity allows inspectors to:

- Reliably detect 1 µm‑scale dust particles, up to 10× better than traditional inspection lamps.

- Catch faint, shallow scratches and micro‑defects even on highly reflective surfaces.

- Increase working distance or inspect larger areas while still maintaining strong defect contrast.

-

Tailored Wavelengths (White, Green‑Yellow, and More)

Sunlonge’s wafer inspection series, including the SL8500/SL8100, uses:

- 6000 K white light versions for general scratch, coating, and contamination inspection

- 510–590 nm green‑yellow light versions that are highly sensitive to human vision and optimized for dust, micro‑scratches, and fine surface irregularities on LCDs, wafers, and micro‑engraving molds

These wavelengths mirror what leading competitors use for surface inspection (white, yellow, green, UV) for wafers, filters, ceramics, automotive paint, and metal surfaces—but Sunlonge combines them with much higher illuminance and stability.

For customers needing specialized solutions, Sunlonge offers additional wavelength options such as 365 nm, 455 nm, 525 nm, 595 nm, 625 nm, and 6000 K white, making it possible to tune the lamp to particular materials and defect signatures.

-

Customized Optical and Filter Systems

A powerful LED alone does not guarantee effective defect detection. The lens, optical path, and filters determine:

- How evenly the field is illuminated

- How much glare reaches the operator’s eyes

- Whether certain wavelengths are blocked or enhanced

Sunlonge invests in customized optical lenses and filter systems that:

- Deliver a controllable irradiated area (e.g., around 120–200 mm at 40 cm for the SL8100, adjustable by dimming)

- Maintain high illuminance stability (>90–95%) so every inspection shift sees the same image quality

- Focus the light where it’s needed while minimizing wasted spill and reflections

This level of optical engineering is comparable to that seen in advanced automated surface inspection systems that pair line‑scan cameras with high‑intensity linear lights for real‑time defect detection.

-

Longer Life and Lower Total Cost of Ownership

Key reliability and cost advantages of Sunlonge surface inspection lamps include:

- LED lifespan of around 30,000 hours—an order of magnitude longer than mercury‑vapor lamps and comparable to or exceeding many competing LED systems.

- Cool, mechanical cooling designs with no fan, improving stability and reducing maintenance needs.

- Low power consumption (e.g., around 20–35 W for a single high‑power LED source in desktop units)

These factors translate directly into:

- Less downtime for lamp replacement

- Lower power bills, especially in 24/7 operations

- Stable light output from shift to shift, which is critical for quality control and traceability

-

Compact Desktop Design with Continuous 24‑Hour Operation

Sunlonge’s SL8500 is designed as a compact desktop wafer surface inspection lamp, with:

- A small footprint and lightweight body suited for workbench and microscope‑adjacent setups

- Continuous 24‑hour operation capability on standard AC power (100–240 V), thanks to efficient LEDs and robust power electronics

- Simple, infinite dimming control from 0–100% for quick adjustment between different samples and operators

This allows quality engineers and operators to integrate the lamp at multiple points:

- Incoming material inspection

- In‑process control (e.g., after polishing, cleaning, or coating)

- Final outgoing quality checks

without needing large, expensive, camera‑based systems for every station.

-

Compliance Culture: ASTM E3022 and ISO 3059 for UV NDT Lamps

Although the SL8500 itself is a visible‑light surface inspection lamp, Sunlonge’s broader product portfolio includes UV NDT lamps designed for fluorescent penetrant and magnetic particle inspection. These UV lamps are:

- Fully compliant with ASTM E3022, the standard for LED UV‑A lamps used in NDT

- Manufactured to align with checklists that emphasize meeting specifications like ASTM E3022 and ISO 3059 for reliability and regulatory adherence

This matters because it demonstrates a company‑wide culture of standards compliance and traceability—not just one‑off marketing claims. Customers benefit from:

- Confidence that Sunlonge designs around internationally recognized benchmarks

- Easier qualification and documentation for aerospace, automotive, and industrial audits

- Consistent manufacturing quality across both UV and visible surface inspection product lines

Key Comparison Table: What Sets Sunlonge Apart

The table below summarizes how a high‑performance Surface Inspection Lamp from Sunlonge compares with a typical generic inspection light, based on published specifications from multiple vendors.

| Parameter | Typical Generic Surface Inspection Lamp | Sunlonge High‑Intensity Wafer Inspection (SL8500/SL8100 Series) |

| Light source | Mid‑power white LED, limited wavelength options | High‑power imported LED (20–35 W) with customized optical and filter system |

| Illuminance at 30 cm | ≈30,000–60,000 lux | ≈150,000 lux (SL8500 class) and up to 350,000 lux (SL8100) |

| Detectable particle size | Small dust and scratches, limited at low contrast | Dust particles down to about 1 µm; ≈10× more powerful than traditional lamps |

| Wavelength options | Often white only; some models offer single green or yellow version | White (6000 K), green‑yellow (510–590 nm), plus optional 365, 455, 525, 595, 625 nm variants |

| Light stability | Not always specified; can drift noticeably over time | >90–95% stability with dedicated optical and filter system |

| LED lifespan | Around 50,000 hours in some units | Around 30,000 hours with very high output and continuous 24‑h operation capability |

| Dimming and beam control | Basic dimmer or fixed output | Infinite 0–100% dimming; irradiated area adjustable via dimming |

| Applications | General surface inspection across few materials | Optimized for wafers, semiconductors, LCDs, micro‑engraving molds, sapphire, coatings |

| Compliance mindset | Limited reference to formal NDT standards | UV lines compliant with ASTM E3022 and aligned with ISO 3059 checklists |

Practical Benefits: How Sunlonge Lamps Improve Your Defect Detection

By upgrading to a Sunlonge Surface Inspection Lamp such as the SL8500 series, quality teams can expect:

- Higher defect capture rate: 1 µm contamination and very fine scratches become clearly visible instead of marginally detectable.

- Faster inspection: High illuminance and larger effective beam area allow inspectors to see more of the part at once, reducing handling time.

- More consistent judgments: Stable, calibrated light output and tuned wavelengths reduce operator‑to‑operator variation.

- Lower cost per inspected part: Long LED life, low power consumption, and minimal maintenance lower total cost of ownership versus mercury‑vapor or generic lights.

- Easier integration with automated systems: Strong, even illumination improves camera image quality in AOI and smart inspection systems.

For organizations working with wafers, flat panels, and precision optics, these benefits directly translate into:

- Higher yield per batch

- Fewer expensive downstream failures

- Stronger customer satisfaction and fewer returns

Q&A: Common Questions About Surface Inspection Lamps

Q1: What exactly is a Surface Inspection Lamp?

A Surface Inspection Lamp is a high‑intensity LED light, engineered with specific wavelengths, optics, and beam shapes to reveal small surface defects—scratches, dust, coating flaws, and structural irregularities—that normal lighting cannot show reliably. It’s used across semiconductors, electronics, metals, glass, and coatings to support both human and automated inspection.

Q2: How is it different from a normal LED work light?

Standard work lights focus on general visibility and comfort. Surface inspection lamps prioritize defect contrast:

- They provide much higher illuminance (often 100,000+ lux at 30 cm)

- They use specialized wavelengths (white, green, yellow, UV) tuned for particular defect types

- Their optics and beam geometry are designed to highlight height and texture differences rather than just flood the area with light

As a result, subtle defects that look invisible under normal light become obvious under an inspection lamp.

Q3: Why are green and yellow‑green lights often used for defect detection?

Human eyes are most sensitive in the green region of the spectrum. Green and yellow‑green wavelengths:

- Make small changes in reflectivity and scattering more visible

- Cause dust, fingerprints, and fine scratches on LCDs, glass, and wafers to stand out sharply

That’s why both Sunlonge and other specialist vendors offer green and yellow‑green surface inspection lamps for high‑precision applications.

Q4: Can a Surface Inspection Lamp replace automated optical inspection (AOI)?

No, they are complementary:

- Surface inspection lamps provide strong, uniform, contrast‑enhancing light that benefits both human inspectors and cameras.

- AOI systems and PL‑based inspection systems analyze captured images and can detect patterns, internal defects, and wavelength variations at scale.

In most advanced manufacturing lines, AOI is paired with high‑quality surface illumination to maximize detection accuracy and throughput.

Q5: Are Sunlonge Surface Inspection Lamps safe for operators’ eyes?

Sunlonge’s visible‑light inspection lamps are designed to be highly effective yet comfortable, using wavelengths that are sensitive to human vision without being harmful when used as directed. Green‑yellow light, for example, offers strong defect contrast while minimizing eye strain compared to overly blue or UV‑rich spectra.

For UV NDT lamps, Sunlonge follows ASTM E3022 and related checklists that emphasize safe UV‑A ranges and low visible light leakage, along with appropriate protective eyewear and procedures.

Q6: Where does the SL8500 fit among Sunlonge’s product range?

The SL8500 is a desktop wafer surface inspection lamp, ideal for:

- Benchtop and microscope‑adjacent inspection

- Small and medium‑sized wafers, LCDs, and precision parts

- Quality labs and in‑line sampling stations

For applications requiring even higher illuminance and wider coverage (e.g., large wafers, full‑panel inspection), the SL8100 provides up to 350,000 lux while preserving similar wavelength options and stability.

Q7: How should I choose the right Sunlonge Surface Inspection Lamp for my application?

Consider:

- Material and defect type

- Scratches and general appearance: start with white light.

- Dust and fine particles on glass/LCD/wafer: choose green or green‑yellow.

- Fluorescent NDT (cracks, porosity): choose UV‑A with ASTM E3022 compliance.

- Required illuminance and working distance

- Small parts at close range: SL8500 class desktop lamps are ideal.

- Larger panels, wafers, or more distant mounts: SL8100 class lamps with higher lux and wider irradiated area.

- Inspection method

- Purely manual inspection: prioritize ergonomics and dimming flexibility.

- Camera‑based or AOI: prioritize uniformity, stability, and mechanical integration options.

A Sunlonge representative can match specific models and wavelengths to your process steps based on your defect map and material stack‑up.

Conclusion: Turning Invisible Defects into Visible Quality

A Surface Inspection Lamp is far more than a bright work light. It is a precision tool that transforms how easily and reliably your team can see micro‑defects that impact yield, reliability, and customer perception. By combining high‑intensity, carefully chosen wavelengths, customized optics, and stable, controllable output, a well‑engineered lamp turns invisible or borderline defects into clear, actionable information.

Sunlonge’s SL8500 desktop wafer inspection lamp, together with its higher‑power siblings like the SL8100 and a full line of UV NDT lamps, delivers:

- Market‑leading illuminance up to 350,000 lux at 30 cm

- Detection capability down to approximately 1 µm dust particles—around 10× stronger than traditional lamps

- Tunable wavelengths (white, green‑yellow, and more) for different defect classes

- Proven stability, long life, and a compliance mindset rooted in standards like ASTM E3022 and ISO 3059 for UV applications

For semiconductor, electronics, optics, and precision manufacturing facilities that want to push yield higher and defects lower, integrating Sunlonge Surface Inspection Lamps into critical inspection points is one of the most straightforward, high‑ROI upgrades available.

If you share specific target industries (semiconductor line, LCD fab, metal coating, automotive, etc.), a tailored content version can be created around your flagship model (SL8500) to align perfectly with those customer segments and their search intent.

CN

CN