Regarding the current situation of the very competitive industrial environment, everybody is worried about the best level of costs entailed. To increase the bottom line, companies wanting operational efficiency have integrated revolutionary technologies into their businesses that offer maximum performance and economic benefit. Of these solutions, the most advanced is the one known as UV NDT (Non-Destructive Testing) lamps, which make great savings supported by excellent numbers.

The Rising Prominence of UV NDT Lamps

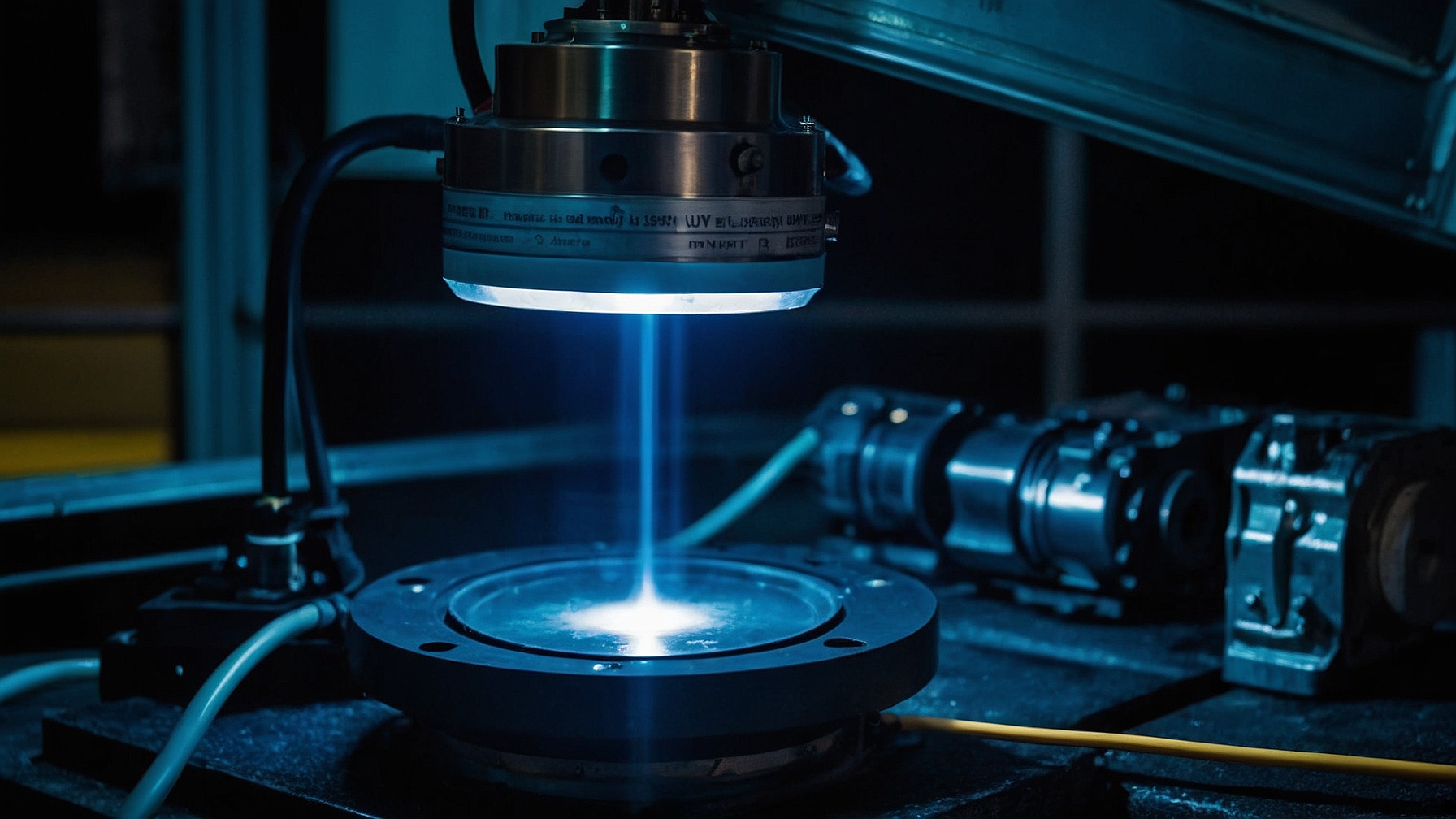

UV NDT lamps have become an effective tool for non-destructive testing and inspection in many sectors: aerospace, automotive, and manufacturing. These lamps work by irradiating ultraviolet light, which interacts with some kind of fluorescent dye or penetrant, thereby giving an indication of defects, cracks, or some irregularity in the materials and parts tested. By being at par with this recent technology, industries can detect precursor problems in time to avoid costly failures and ensure quality and safety.

Statistical Insights: Unveiling the Cost-Saving Potential

Numerous studies and real-world implementations have demonstrated the significant cost savings achieved through the adoption of these lamps across diverse industrial sectors. Let’s delve into the statistical evidence that illuminates their economic impact:

Aerospace Industry

A comprehensive analysis by the National Aeronautics and Space Administration (NASA) revealed that the incorporation of these lamps in aircraft inspection protocols led to a remarkable 27% reduction in maintenance costs. This substantial saving can be attributed to the early detection of potential issues, enabling timely and cost-effective repairs, thereby minimizing the risk of more extensive and expensive interventions.

Automotive Manufacturing

According to a recent report by the Automotive Industry Action Group (AIAG), automakers that embraced the NDT lamp technology experienced an average cost reduction of 18% in their quality assurance processes. This cost-saving stems from the ability to identify and address manufacturing defects early in the production cycle, minimizing the need for costly recalls and warranty claims.

Oil and Gas Sector

A study conducted by the American Petroleum Institute (API) highlighted that the implementation of NDT lamps in pipeline inspection procedures resulted in a 22% decrease in operational costs. By accurately detecting minute cracks, corrosion, and other flaws, these lamps facilitated proactive maintenance, mitigating the risk of costly leaks, environmental incidents, and production downtime.

Power Generation Industry

The Electric Power Research Institute (EPRI) reported that utilities incorporating UV NDT lamps into their inspection protocols for turbine blades and other critical components experienced a 16% reduction in maintenance expenditures. This cost-saving can be attributed to the early identification of potential failures, enabling timely repairs and minimizing unplanned outages, which can incur substantial financial losses.

Manufacturing Sector

A comprehensive analysis by the National Institute of Standards and Technology (NIST) revealed that manufacturers leveraging UV NDT lamps in their quality control processes achieved an average cost saving of 14%. This economic benefit stems from the ability to detect and address defects early in the production cycle, minimizing waste, rework, and the associated labor and material costs.

Beyond the Numbers: Auxiliary Benefits

While the statistical evidence underscores the significant cost savings achieved through the adoption of UV NDT lamps, their benefits extend beyond mere financial considerations. These innovative light sources contribute to enhanced safety, improved product quality, and reduced environmental impact, further solidifying their value proposition.

Improved Safety

By enabling the early detection of potential failures and defects, UV NDT lamps play a crucial role in mitigating safety risks associated with component failures or system malfunctions. This proactive approach not only safeguards personnel but also minimizes the likelihood of costly accidents and liabilities.

Superior Quality Assurance

The precision and accuracy of UV NDT lamps in identifying even the most minute flaws ensure that only products of the highest quality reach the market. This commitment to excellence not only enhances customer satisfaction but also strengthens brand reputation and long-term competitiveness.

Environmental Sustainability

The non-destructive nature of UV NDT lamps eliminates the need for invasive testing methods, reducing the generation of waste and minimizing the environmental impact associated with traditional inspection techniques. This eco-friendly approach aligns with modern sustainability initiatives and contributes to a greener industrial footprint.

Final Thoughts

The statistical evidence presented in this article undeniably demonstrates the significant cost savings achieved through the adoption of UV NDT lamps across various industries. From reduced maintenance costs and extended equipment lifespan to improved productivity and decreased warranty claims, the economic benefits are multifaceted and substantial. As industries continue to prioritize cost-effective solutions without compromising quality and safety, the integration of UV NDT lamps emerges as a strategic investment with far-reaching economic implications. Embracing this innovative technology not only offers immediate cost savings but also paves the way for long-term operational excellence and competitive advantage.

CN

CN