Introduction

Over the long development of fluorescence systems, multiple devices and dyes have been created, providing countless solutions to different industry problems. To maximise the effectiveness of the operation, choosing an appropriate UV fluorescent dye along with a UV light becomes a critical process, generating a reliable result from the data.

Application Recommendations

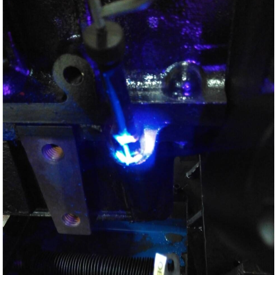

In general, the introduction of a UV fluorescent dye into the engine can be implemented in two ways. First, the engine oil and dye can be premixed and added to the engine before testing. Second, the engine oil can be added to the engine, followed by the dye. By examining the engine with a black light, typically speaking, with a wavelength of 365 nm, the leakage will create a white-yellow fluorescence.

Advantages of UV Fluorescent Dyes

- High sensitivity – Compared with absorbance measurements, fluorescence measurements produce a 1000x sensitivity, achieving a detection limit of parts per trillion (ppt), even with a small sample size.

- Wide linear dynamic range – The fluorescence test is capable to produce an output that is completely proportionally to the sample concentration.

- Low interference – In contrast to spectrophotometric measurements which often result in interference problems due to the great number of materials absorbing light, fluorescence measurements involve a limited number of fluorescent materials, minimizing the extent of interference, and increasing the accuracy of the test.

- High throughput – In a high throughput application, that involves a large area of inspection and contains numerous materials for inspection, fluorometric measurements with a simple and efficient protocol allow automation and cater to diverse needs.

Factors to Consider

- Compatibility with the design of the experiment – Given the enormous number of applications of UV fluorescent dyes, each experiment carries individual requirements and characteristics. Accordingly, the foundation of choosing the right dye lands on its compatibility with the application. In particular, each dye involves various functionality, extinction coefficient, excitation and emission wavelength, band shape and width, and photostability.

- Extinction coefficient – Extinction coefficient is defined as the ability of a medium to absorb or reflect radiation or light at a particular wavelength. In other words, a higher coefficient illustrates a higher ability to highlight the defects or flaws.

- Quantum yield – Quantum yield, calculated by dividing the number of emitted photons by the number of absorbed photons, measures the efficiency of a fluorescence process. A UV fluorescent dye with a high quantum yield can therefore produce a strong fluorescence.

- Avoid photobleaching – Photobleaching refers to a photochemical destruction process that lowers the intensity of fluorescence. To avoid photobleaching, it is recommended to apply photostable fluorophores and reduce the exposure time to the excitation light source.

- Emission spectra – In multicolor experiments, a narrow emission spectrum should be concluded with a broad emission. This can reduce the risk of spectral overlap, and the detection of one fluorophore in another fluorophore’s filter set, leading to confusion in the observation of the experiment results.

- Compatibility with the equipment – Considering the diversity of equipment used, taking the instrument’s sensitivity, dynamic range, stability, throughput, signal-to-noise, and signal-to-blank ratios into account can undoubtedly enhance the matching of emission profile between them.

- Compatibility with other fluorescent materials in the sample – When conducting double or triple labeling experiments, the emission and excitation profile of the dye should be differentiated from other fluorophores, for instance, blood or oil. By doing so, the sign created by the dye can be clearly identified from the background. Taking the SL3200 leak detection fluorescent dye from Sunlonge as an example, specifically designed for oil leakage detection of gasoline and diesel engines, the dye produces an intense white-yellow fluorescence, which can be differed from the natural blue fluorescence found in several oils, providing an effective location.

Conclusion

Thanks to the rapid development of technology, the number of UV fluorescent dyes on the market has been constantly increasing. However, aiming for a reliable and stable result with an uplifted efficiency, the choice of dye has to be thoroughly considered by analyzing the above factors. With the support of a suitable dye, fluorescent leak detection is able to locate both elusive and intermittent leakage that could be easily overseen with traditional methods.

CN

CN