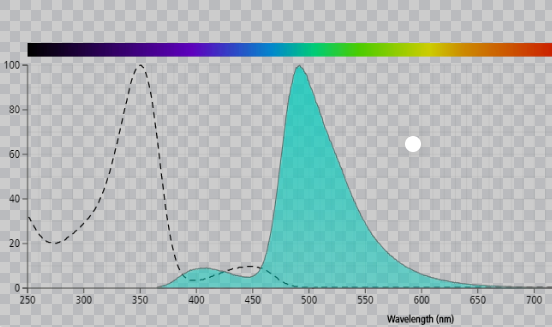

In order for the fluorescent leak detection to work optimally, high-quality crack testing agents with outstanding fluorescence properties are required on the one hand, and state of the art UV LED lamp technology on the other. This is the the only way to carry out fluorescent leak detection efficiently and reliably and to reliably detect leaks.

Fluorescent leak detection is a simple method often used in the field of NDT to safely and cheaply detect leaks in engines, HVAC system and much more. Fluorescent leak detection is suitable in any liquid circuit of machines and systems.

On one hand, leaks can be quickly identified with fluorescent leak detection. Many companies also use the fluorescent leak detection to prevent machine failure, expensive repairs and damage.

The actual process of fluorescent leak detection is quite easy. You add the fluorescent UV dye into the system. Wait several minutes until the dyes are properly distributed in the liquid circuit. Then scan the system with a UV lamps. The leaks can be glowing brightly under the UV lights.

An undetected leaks in an industrial engine and leaking oil can quickly leak to production coming to a standstill or unnoticed pollution of the environment with every drop of lost liquid and at the same time high costs arise in the company. This is exactly where fluorescence leak detection comes in, because it is safe, efficient and cost effective.

Another focus for many companies is in the area of security. Occupational safety and sustainable production are becoming increasingly important and are increasingly in the focus of companies. The forward looking and preventive use of fluorescent leak detection ensures that the products produced are cheaper and more sustainable and can also be marketed accordingly.

Fluorescent leak detection is in most cases a worthwhile investment that pays off on its own. But very important, make sure that you have a well-coordinated leak detection system in use. Otherwise, a deceptive security can arise because there could be leaks are not detected, even though you have established fluorescent leak detection in the company.

The key parts for fluorescent leak detection are fluorescent UV dye and a UV lamp. This makes the fluorescent leak detection easy. Moreover, it depends much on the system to be investigated and the objective of leak detection, which the fluorescent UV dye and the UV lamp you need to buy.

Sunlonge, the leading manufacturer of UV equipment and fluorescent materials, is working with partner in this field for more than 15 years. Now Sunlonge can offer a comprehensive and reliable fluorescent leak detection solution for customer in HVAC and automotive industry. We will be rooted in this industry and offer more reliable and efficient products for our customer in the future.

CN

CN